PLA printing yields in pancake

Hey there,

for the first time I've been trying myself on TPU printing with my Prusa. However, no matter what I do, my prints end up as flat as a pancake even though they go through the whole printing progress and show up as 100% done with no errors.

Switching to PLA yields in perfect prints again without me chaning anything.

This is what it is supposed to look like.

Appreciate any input!

PLA of TPU?

Hi Alex,

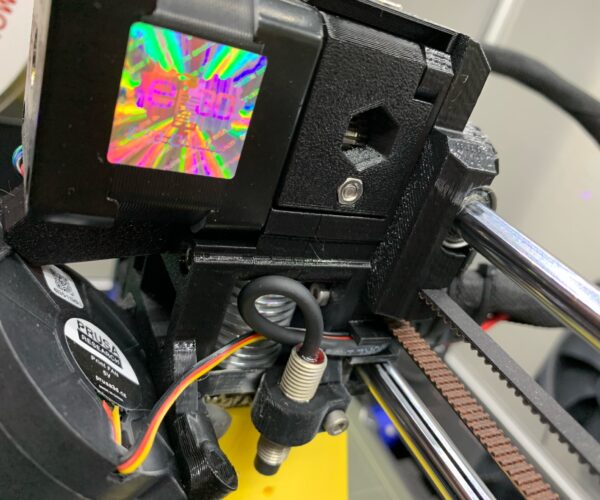

did I understand correctly that the mess happens when using TPU? (Your post title suggests PLA and the image also looks like PLA to me).

But anyhow, TPU is a nasty beast to print with until you got it sorted out. Your learning curve will be a long and flat one, but once sorted you can do really nice things with flexible filaments.

Instead of going through everything that has been written about printing with flexible filaments, I rather recommend you look around the web for what all the smarter people have written about it.

But for your specific print, it looks to me as if the printer stopped extruding at some point and was just going through the xyz motions without anything coming out of the nozzle. One of the main differences between flexible and more rigid materials is that you need almost no extruder idler door pressure. A lot of people (including myself) unscrew the thing completely and then screw it back in until it just about catches the thread of the nut.

Too much pressure on the gears either make it slip (yes sounds counter intuitive but the teeth just chew the filament instead of transporting it) or even worse grab the filament and wind it nicely around the gears instead of pushing it through the tube.

That was my first attempt at printing this beautiful Kermit green TPU 😉

The other thing that you might want to consider is temperature. The above green filament should be printed at 190-220 degrees. This temp contributed a lot to the slow flow that increased the pressure in the extruder which ultimately contributed to the filament winding around the gears. Without a temp tower, just try and error I ended up at 240 degrees for the first layer and 235 degrees for the rest. Can't remember how exactly I arrived at those numbers but the stuff now prints nicely (if I don't forget to dry it before printing).

hth

Hansjoerg

The basic rule with all flex printing is absolute minimal extruder pressure as @hawai writes and print it slooowly; no, slower than that.

Your picture suggests your settings are close but when you get to the point that the filament must stop and start, which means retraction, the pressure fluctuations in the hot end are not given enough time to even out...

So slower.

That said I am finding it difficult to relate the failed print to the slicer output; please save your project as a .3mf, zip it, and post it here so we can review the settings.

Cheerio,

agree with hawai

Exactly that thing happened to me the very first time I tried to print tpu. I got the tpu wrapped around the extruder gear 4 times, requiring disassembly each time, before I figured it out.

Generally to have success with TPU.

1. Loosen idler bolt. I find that having the idler bolt's tip flush with the hex nut surface(just below the hex window) works for tpu and rigid filaments and I don't have to mess with it.

2. Tpu is hygroscopic. That means it absorbs moisture. You might invest in a filament dryer if you're going to be doing a lot of tpu printing. I had two spools of ninjaflex recently, black and red, that I had to print with a higher temperature than usual(248) to get solid results, or else it stopped extruding just like yours. The higher temp prevents the back pressure in the nozzle.

3. SLOW print speed. This is generally taken care of if you pick a filament profile that is FLEX. My best success is to start with the Semiflex Flexfill 98a profile and adjust the temp for the particular tpu I'm printing with. PS magically slows down the printspeed to like 35 percent when the type of filament is FLEX and generally you don't have to mess with the speeds under the print settings.

4. If printing on the smooth sheet, you should put a release agent down like glue/layerneer/magigoo since TPU tends to stick REALLY well.

That's all.

You did reslice

Probably being pedantic here but "Switching to PLA yields in perfect prints again without me chaning anything" except reslicing for PLA right?

very good question

@towlerg

Yes, that's a great question. if one doesn't reslice for tpu and pla, I could see pla settings causing the under-extrusion and the speed would be too high also. Hopefully OP answers