Re: PLA Filament problem - extruder stops extruding filament

I know you've done a lot of this, but here's my standard list of things to check:

During my troubleshooting I've gone over each of these things, and have made sure everything is how it should be to no avail. I even reduced the volumetric speed to less than 11.5mm/s (using Slic3r PE). However, every single one of my PLA prints fail regardless of material. My issues are exactly like gerardo.w and neil.f3 describe: material will flow just fine during loading or when manually pushing material through, but a few hours into a print it suddenly stops as if there was a complete jam. I will say that when I unload filament from the extruder, there is a slight "glob" at the end of the material, but I always assumed that was normal. I'll post a photo later today if I can.

Overall, I would have expected that doing extensive troubleshooting would have resolved the issue, but it looks like this may be either a design or software flaw. I've been starting to see more and more people with this problem too (both here and on the Prusa3D subreddit) so the Prusa team should really be looking into this.

Re: PLA Filament problem - extruder stops extruding filament

I agree on what written by @bobstro.

The issues seems all the same. I'm in doubt if thats a temperature problem as well, even if srtange that some PLA works, other not...

BTW the next days I'll upgrade to R3 parts, hoe that helps.

As soon the weather outside is better (cold), I'll try another print.

The stepper motor becomes really hot, maybe because it's not able to push the filament.

Simon

Re: PLA Filament problem - extruder stops extruding filament

There's something going on with some printers. I did a 7 hour print during a warm day here (77F/25C ambient room temp) with a bit of rigid.ink PLA taped to my extruder as a test since I don't have a better thermometer. rigid.ink has a very low melt temp. All the way through, the extruder stayed warm but I was quite comfortable with my fingers on it. The filament was curved upwards and never softened. The extruder motor getting that hot is definitely not normal. The problem with simply cooling is that it doesn't fix the underlying problem.

[...] The stepper motor becomes really hot, maybe because it's not able to push the filament.

Can you share one of the problem STLs? Might be interesting to look it over. Maybe your gcode file too?

Re: PLA Filament problem - extruder stops extruding filament

Pardon my noobeté... Jes' spitballin' here. Has anyone looked at this from the other end? Some of these symptoms sound like they could be from the extruder end or from the spool hanging up(?)

That's "MISTER Old Fart" to you!

Re: PLA Filament problem - extruder stops extruding filament

Personally, I use the standard setup that the newest version of the MK3 spool holder (double sided nylon spool holder). When I put spools of filament on, they both rotate freely. Besides, if it was the spools of material causing the failure, I think it would happen to every material that is used, not just PLA.

Personally, I think my next step is going to be either buying a filament from a different company to see if it's a manufacturing problem, or contacting Prusa tech support directly. I really don't like the idea of having to buy new material though, because the ones I bought came from Prusa!

Re: PLA Filament problem - extruder stops extruding filament

I have found this link that might help to understand what I think we are talking about:

http://www.sublimelayers.com/2016/10/some-musings-on-retracts.html

From my point of view it explains the physical background of the issue.

Since PLA is one of the most popular filaments used on FDM printers, the market offers a wide range of PLA grades. But how do they differentiate from each other? Just by the color and price? Definitely not! And can all printers process all kinds of PLA´s? I don´think so.

As stated before, I can print until now any geometry with the PLA deliverd with the kit. As soon as I replace it against the local grades from JANBEX, the jamming issue starts. And I am comparing exactly the same print, with the same gcode at the same printer conditions.

The PLA grade itself plays an important factor here.

@bobstro: thank you for taking your time to help us.

Re: PLA Filament problem - extruder stops extruding filament

Personally, I use the standard setup that the newest version of the MK3 spool holder (double sided nylon spool holder). When I put spools of filament on, they both rotate freely. Besides, if it was the spools of material causing the failure, I think it would happen to every material that is used, not just PLA.

Could be the spool, the holder, the wind, or other... If, for example, Mfr. A had a batch of spools with burrs (or flat spots, or whatever...) on them, and they all wound up on the PLA line...

Like I said, I was jes' spitballin'. If you can definitively rule out things from the spool end...

Whatever the cause, I hope you folks can solve it.

That's "MISTER Old Fart" to you!

Re: PLA Filament problem - extruder stops extruding filament

Things I've replaced so far in the extruder assembly alone:

-Thermistor

-Heat block

-Nozzle

-Heat break

-extruder pulley set screw

-Printed components

-ptfe tube at top of filament load

Things I've yet to replace:

-extruder pulley gears

-extruder motor

-heat sink

-fans

-ptfe inside heat sink

I'm running out of things to replace that could cause this issue, annoyingly. But I still have the issue.

Re: PLA Filament problem - extruder stops extruding filament

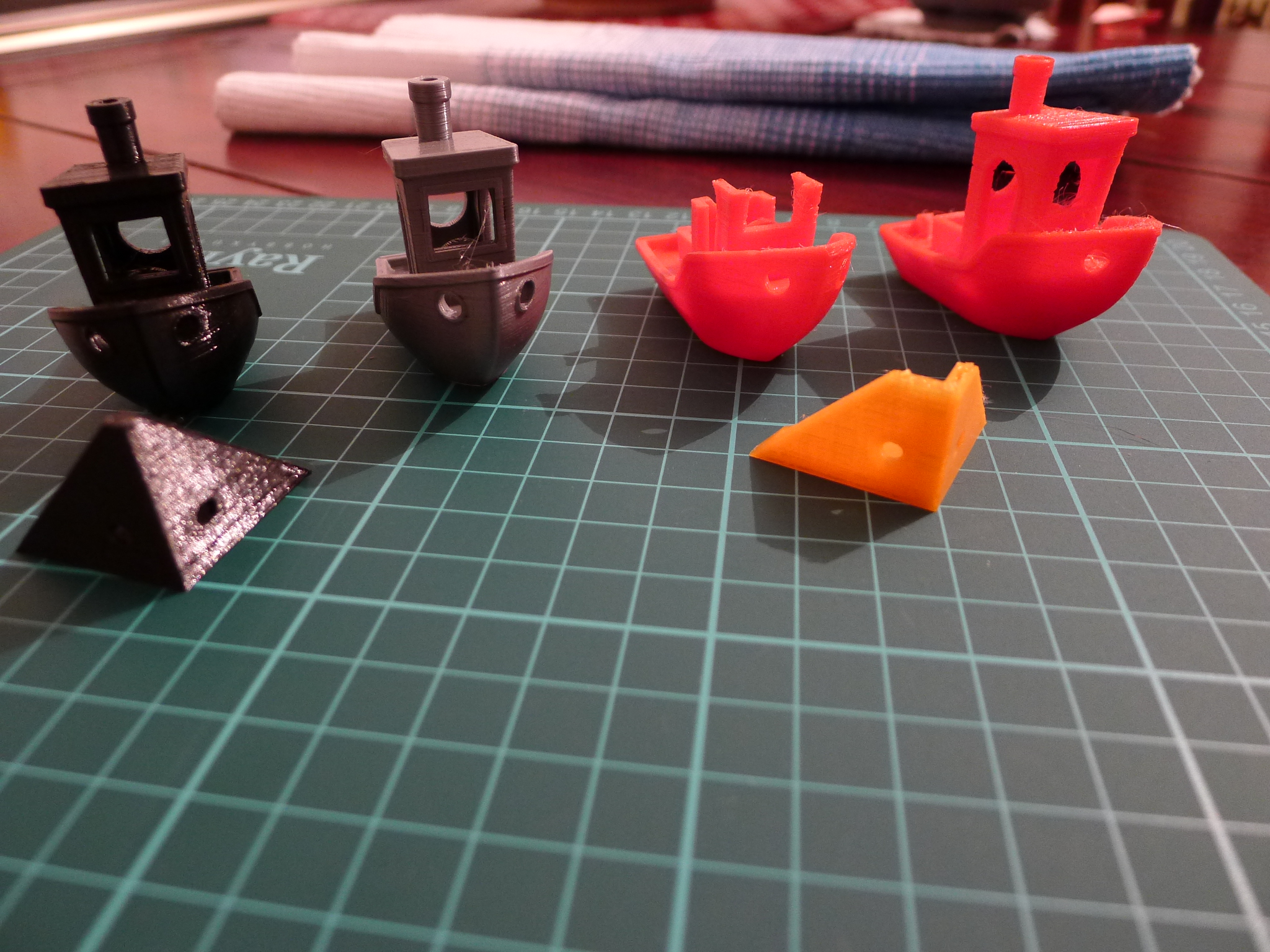

I've got some photos of what my failed prints and filaments are looking like:

You can see in the first picture that a large chunk gets taken out of the filament by the gears to the point where it's no longer able to push material downwards. After what @gerardo.w posted about retraction though, it looks like the glob at the end of the filament could be caused by retraction settings and thus creates a kind of blockage in the nozzle. This might make sense, because based on the failed print, it looks like the amount of material being extruded becomes less and less until eventually nothing comes out.

I used the article to change my retraction to .6mm at 50mm/s and the detraction to only 20mm/s instead of 35mm/s both ways. Printing a test now to see if this has any affect. Wish me luck!

Re: PLA Filament problem - extruder stops extruding filament

@Timothy: good luck!

All the filaments unloaded from failed prints by extruder blockage had exactly the same shape as the picture you posted by Timothy. On side is "bitten out" by the extruder motor gears, the other side (hot end/heat break) shows a local increase on the diameter.

I will make some more tests by reducing the z-hight in order to squeeze less material against each other (PLA).

Today I started printing for the very first time with PET. Looks pretty much good. Let´s see how it performs with the larger prints 🙄

Re: PLA Filament problem - extruder stops extruding filament

UPDATE

No good news so far. I attempted to print the same model as before, but with better retractions. No effect. Print failed after about an hour. So, just to make sure the model wasn't the issue, I tried printing out a 3DBenchy using all default Slic3r settings and my .25mm nozzle at .05mm layer height. And I set a new record! Print failure after only 21 minutes! Same failure method as before: tell-tale clicking followed by diminished extrusions until the nozzle is just floating in the air not extruding.

I'm going to try again with a different nozzle, layer heights, and redried material, but for now, would somebody mind looking at my configuration and gcode? I might just be missing something in there.

My Slic3r configuration: https://drive.google.com/file/d/1zO46tv37rbf9uICJiXRFFJs5oyZBumxb/view?usp=sharing

My 3DBenchy Gcode: https://drive.google.com/file/d/13AnZHrfcC0ydfjT8mkdIw41K-INkDB94/view?usp=sharing

And the stl I used just for kicks and giggles: https://drive.google.com/file/d/1L8RVeUE2iRmvRLmIu9uBRmFTMYrPtSm-/view?usp=sharing

Thanks for the helpful suggestions so far. I'm back off for some more troubleshooting. Might try tearing apart my hotend and cleansing it soon.

Re: PLA Filament problem - extruder stops extruding filament

Hello!

Maybe I've some good news (I hope).

Someone - Somewhere has written that the NEMA17 used to load the filament gets hot and it's possible via "M" codes to reduce the voltage.

Reducing voltages means (I think!) reducing accurancy.

Could be possible that in some last update the voltage was increased and now the NEMA17 gets too hot?

Mine too, but I wont to reduce in accurancy, so I've tried to reduce the temperature.

I was thinking that the problem on the filament was not the hobb-goblin and it's strong on the filament, but it's temperature instead. All pictures are same as mine first post, so assuming the hobb-goblin is tighten more or less good, what happens if the NEMA17 gets too hot?

Well, the hobb-goblin gets hot as well, the filament starts to became soften and then it's not more able to have a grip on it and push it down.

As result, the filament stays in place, the end on the extruder increase the diameter of the filament due it's stopped there without extrusion.

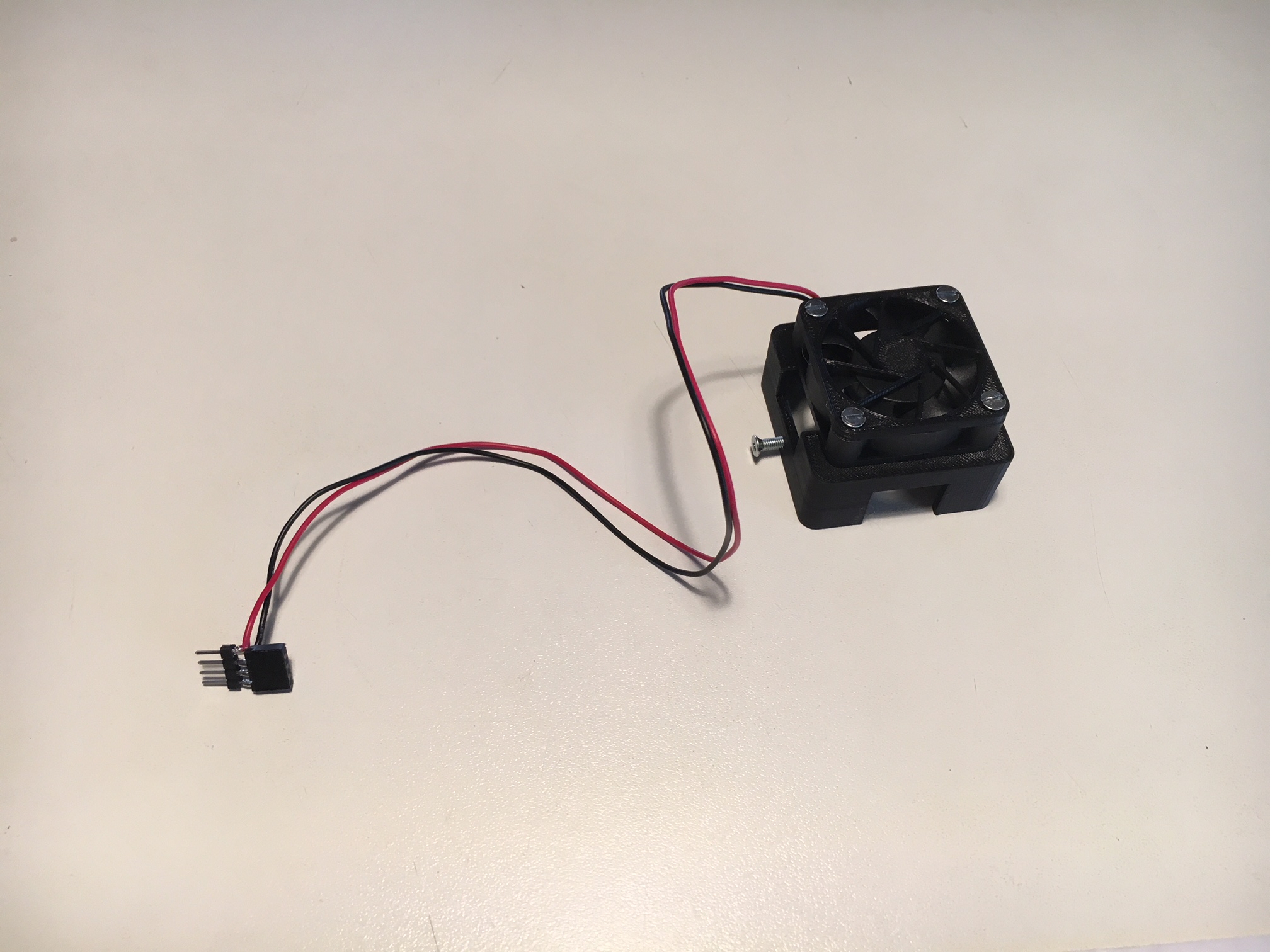

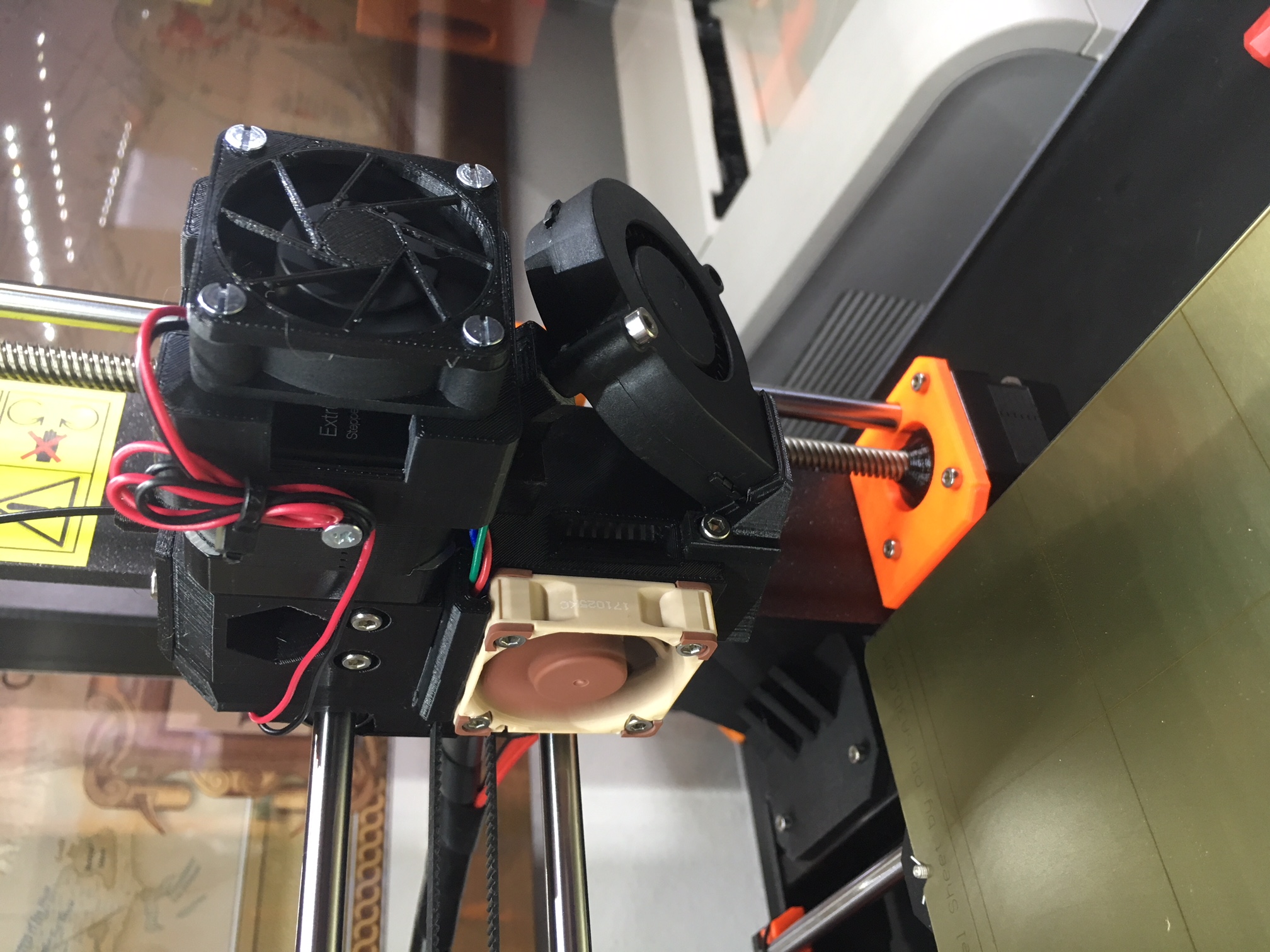

So, I've tried this ( https://www.thingiverse.com/thing:29572 ):

And here mounted:

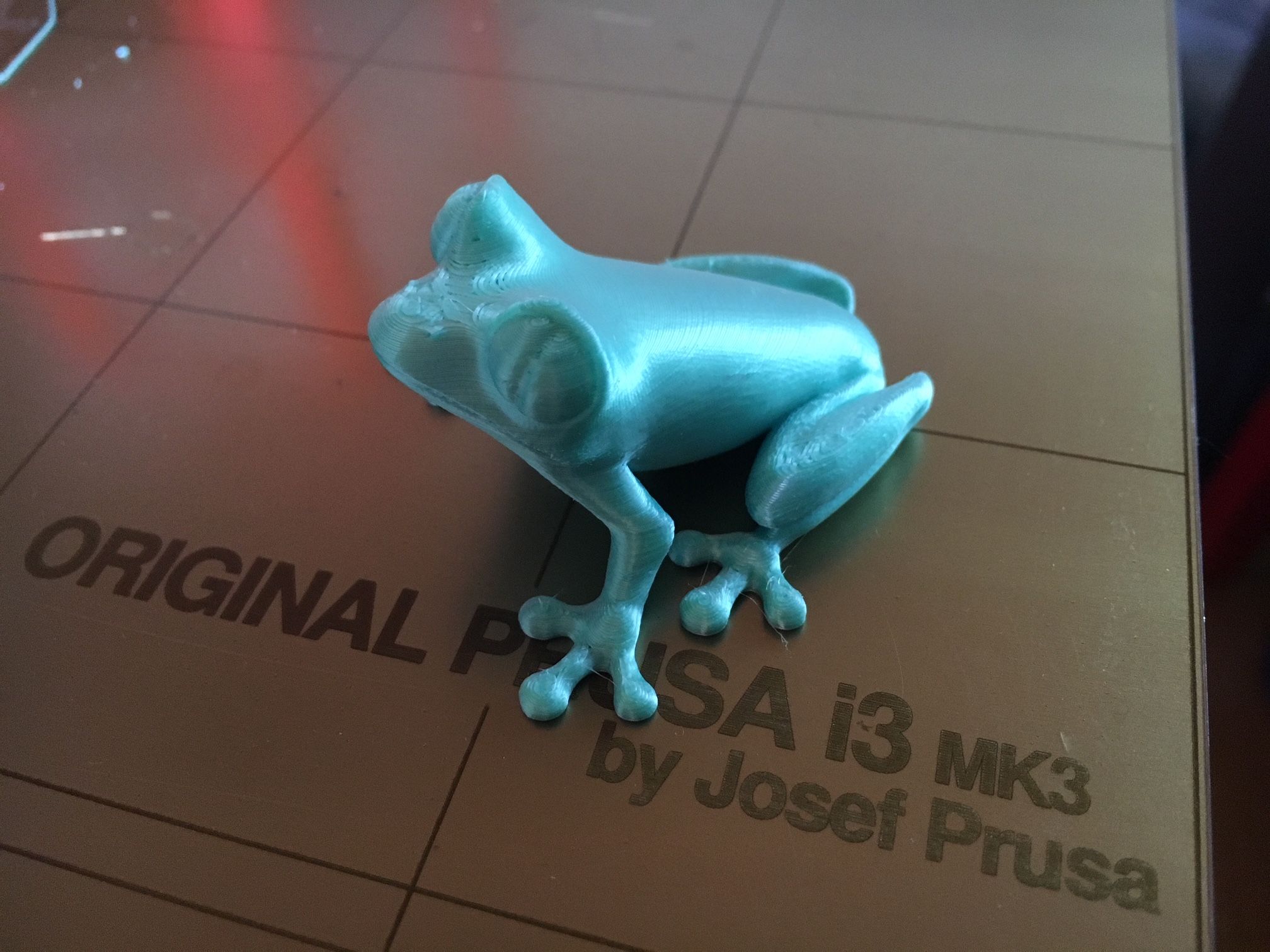

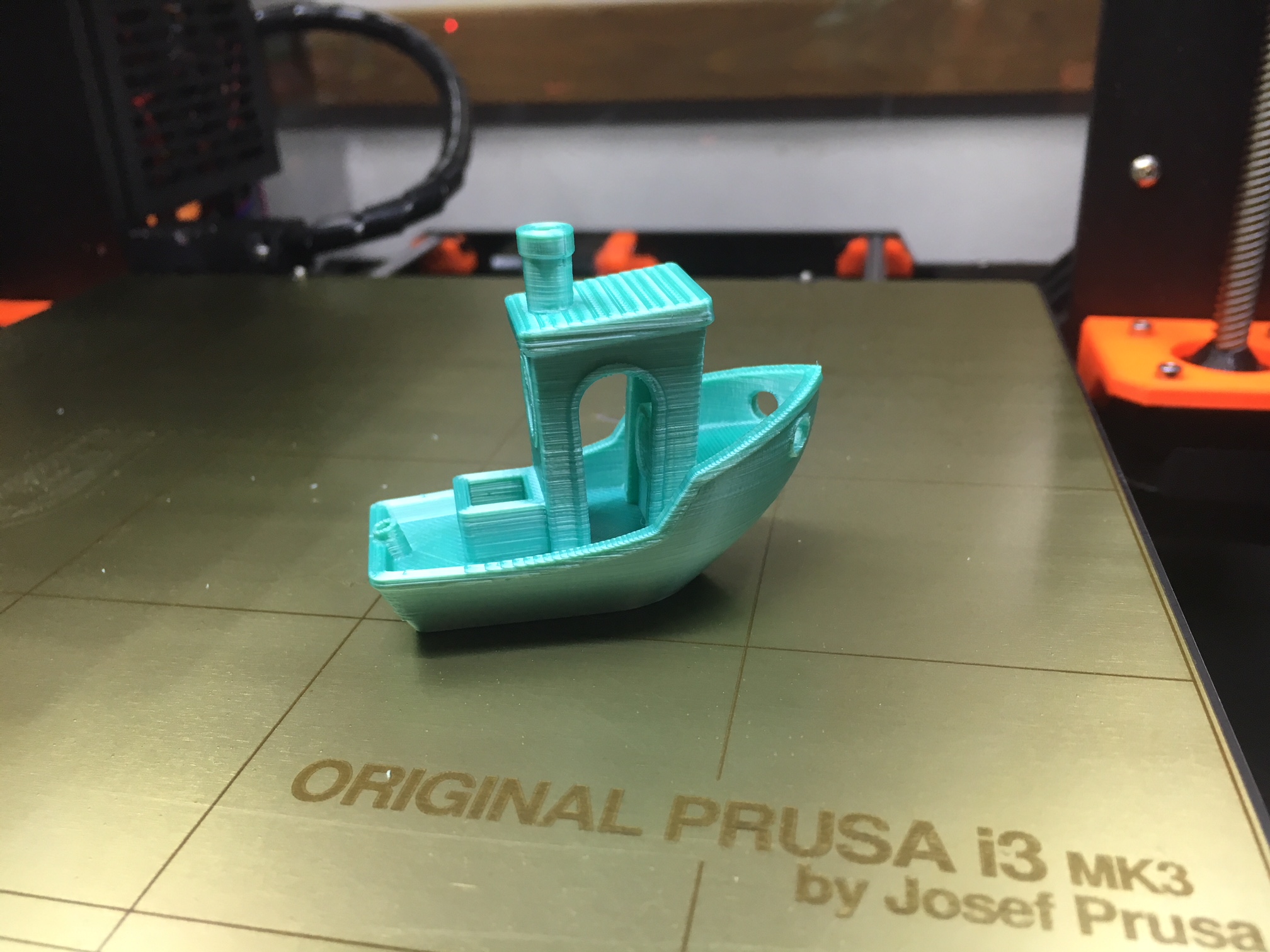

And here the result:

I've still got some problems on the unload. Maybe the filament, after the print, was still too much at the end on the extruder and the unload was a little difficult.

This is my first test, so more to come....

Hope that helps a little!

Simon

Re: PLA Filament problem - extruder stops extruding filament

Another update.

I've tried the 3DBenchy test in 0.15layer, default Prusa Slic3r settings.

First try, failed. Then I've reduced the retraction speed from 35mm/s (default) to 25mm/s.

Result, succeeded:

Good quality so far. The picture shows more details not so clean in real 😛

Simon

Re: PLA Filament problem - extruder stops extruding filament

@Timothy: I think a smaller nozzle makes all the issue even worse.

Your stl file looks exactly like mine. Same volume, same size, same facets.

Here my findings:

Black Benchy and triangle with PET. ---> ok.

Silver Benchy with Prusas Silver PLA ---> ok.

Red Benchy with yellow trinagle with Janbex PLA --> not ok, extruder jams at high retraction areas

Red Benchy Janbex PLA with retraction set to ZERO --> no jamming, but a lot of stringing

Original Ø0.4mm nozzle. G-codes with default values. No enclosure, no octoprint, file transfered with sd card, dry fialment, clean filament...and so on :geek:

So my guess, the filament itself plays an important role too, but of course the number of factors that might lead to a bad print are very difficult to have under control.

By the way, how were your printings at the very start, when your printer was new?

@ all: when holding my hand on the top of the heated bed, I can feel the radiation heat comming from the bed.

Would it make sense to make put a thin sheet of refelctive material on the bottom side of the extruder? I mean does the extruder become so hot only because of the current used to keep it in position and to move it? ❓

Re: PLA Filament problem - extruder stops extruding filament

[...] Would it make sense to make put a thin sheet of refelctive material on the bottom side of the extruder? I mean does the extruder become so hot only because of the current used to keep it in position and to move it? ❓

I feel for everybody having the extruder heat issues, but I'm not about to go adding a lot of weight and complexity to my printer to deal with heat without trying to figure out why it's so hot to start with! The more stuff you add to the extruder, the move weight it has to move around and the more likely print quality will suffer.

I'd definitely check out every other alternative 1st!

Re: PLA Filament problem - extruder stops extruding filament

Hi guys,

I'm even more convinced that the extruder temperature is not the problem, or better is a side problem, and more and more the opinion my guess should be not so far from the real cause.

Again, take a look on my piece of filament and on the filament of @Timothy. They are very similar. In which way? Well, both has the end thicker. Initially I was thinking that is a cause, but I think it's more a side effect. You can clearly notice that the filament at the hobb-goblin gear pulley, the filament is deep scratched. I don't think because the extruder gets too hot, instead because the NEMA17 which pushes the filament down to the extruder, gets too hot. The head is propagated to the hobb-goblin gear pulley, they start melting or better makes the filament soften. The rest comes easy. A soften filament is not able to be pushed down and, instead, it gets scratched and will stay in place. As side effect, the extruder remains hot, because a print is in progress, and the filament end gets thicker.

What above (my personal opinion!) would explain those aspects:

The reflection material proposed by gerardo.w is, on my opinion, not the solution, because the problem comes not from the nozzle, but from the NEMA17.

And yes @bobstro, you're mainly right. Adding material to the extruder is not the best choise. It's altering the weight of the extruder. My solution is still really light but if I could avoid, that would be better.

Another way was what pruposed by nathan.d2:

Motor temperature is normal with this amount of current.

You can lower the temp(lower current to extruder), by entering this into the gcode of your printed object :

M911 E25

M912 E25

Default is E30. so the lower the number, the lower the current. (ie less than 30)

The reasoning behind this high current is that we need the maximum available force to extrude. If you lower this number, you will have less power and need to extrude slower to avoid skip steps. If your motor doesn't skip steps by lowering the E value, then you can enter this more permanently via firmware, slicer etc.

This could make sense give a try, but I would avoid reducing power to the motor stepper 'cause now I'm able to print with default settings and good speeds. And would avoid to reduce speeds to prevent skipping steps.

Maybe someone else could give it a try? I'll plan to do it in case in the next days.

Meanwhile, this night, 12hours or print, without problems, on PLA (but this PLA was never used before, so this could not be affected btw).

My 5 cents!

Ciao, Simon

Re: PLA Filament problem - extruder stops extruding filament

Hi guys,

the last extruder jamming just destroyed a 17 hours print! 😡

I have come to the conclusion that the main issue here is the filament. And I will try to explain why:

PLA (poly lactid acid) is a semi crystalline polymer with a glass transition temperature (softening temperature) that lies very near to the melt temperature. So PLA starts to get soft between 50 and 65°C (Tg) and starts to flow around 180°C (Tm). Means the heat break has to separate a tempearture difference of 130°C (delta T = Tm-Tg) on a very short lenght. Is it possible to do the job? Yes. BUT, unfortunately not all PLA´s are the same and not all extruders perform the same. Some filaments will start to get soft earlier and other will remain stiff at the same condition. This is mainly because the transitions (hard to soft ---> soft to melt) relate with statistical averages of the polymer chain lenghts and the number of molecules the have a specific chain lenght. So one PLA with many short molecules will behave differently from one with many long molecules.

Can we have an influence on that? NO, because the only criteria to buy one or another filament is just the PRICE and the COLOR, but not the molecular weight distribution or the material data sheet that includes maybe a differential scanning calorimetry, or at least the melt flow rate, heat deflection temperature...and so on.

So, I can imagine why some people here claim no have not the same problems as others do. The very first reason is because even we build the kit as carefully as we could...there is a relative big chance to have some hidden setting or assembly error that makes our printer to perform ouside the normal expected range. Second, there is the software also inbetween (slicer, 3D model, design). And third, there are these big amount of filaments on the market, where one filament can be so much different from the other, even we are talking just about "red or blue PLA"

Motor is getting hot--> perhaps as a consequence of the jamming

Motor needs more or less current --> maybe, but why do you need suddently more power to do the same job: squeeze melted filament

How much hot gets the motor? I measured on the housing 48 +/-2°C on a 4 hours print. Perhaps the shaft also gets hot, but the filament remains certainly below 50°C before reaching the heat break . The scratches are due to mechanical grinding.

The jamming is triggered specially on PLA´s because the material becomes soft, where it should be rather still hard. Here I agree with simone.f, but the main factor is the PLA itself, because as I mentioned before, Tg and Tm are very close to each other, and the PLA filaments can be also extremyl different from each other. That´s also why the same FDM Printer needs different power to reach the same volumetric flow with different PLA´s.

So what is my next step: first I will be more carefully when choosing my filaments. Why? Very simple reason: in my case all the clogging or jamming issue started just when I changed the filament brand.

And no, the heat reflection sheet did not improve anything. It just looks nice.

And because I still have 4kg of the "bad" PLA, I will give it a try and cool down the motor with an additional fan, just for fun 😀

Re: PLA Filament problem - extruder stops extruding filament

I had this during the heatwave in the UK. Prior to that, I had not experienced it in nearly 6 months of owning the Mk3 and after a lot of hair-pulling, pointing a deskfan at the printer "resolved" the issue. The R3 parts revision made the issue go away without needing the desk fan pointing at the printer.

PLA itself is not to blame, it is the easiest to print baseline by which other materials are measured. It's the printer.

Re: PLA Filament problem - extruder stops extruding filament

(...)

I have come to the conclusion that the main issue here is the filament. And I will try to explain why:

(...)

Of course PLA with soften point lower gets this problem easier, but I don't think it means it's not a goot PLA.

Motor is getting hot--> perhaps as a consequence of the jamming

I don't think it's a consequence. In my case the motor is hotter than 50°C, it's near untouchable! Maybe it's then mostly my problem.

Motor needs more or less current --> maybe, but why do you need suddently more power to do the same job: squeeze melted filament

How much hot gets the motor? I measured on the housing 48 +/-2°C on a 4 hours print. Perhaps the shaft also gets hot, but the filament remains certainly below 50°C before reaching the heat break . The scratches are due to mechanical grinding.

I'll tell you the exactly temperature. I've purchased yesterday a laser temperature sensor 🙂

The jamming is triggered specially on PLA´s because the material becomes soft, where it should be rather still hard. Here I agree with simone.f, but the main factor is the PLA itself, because as I mentioned before, Tg and Tm are very close to each other, and the PLA filaments can be also extremyl different from each other. That´s also why the same FDM Printer needs different power to reach the same volumetric flow with different PLA´s.

I think then it's caused my different factors. Mainly on hot room temperature. I've never had this issues before. stuart.b4 the same. Then the motor temperature in conjunction with a pla that gets soften easier. BTW, reducing the motor temperature, the problem was (FOR NOW!) solved. Hope that it remains so 😉

And because I still have 4kg of the "bad" PLA, I will give it a try and cool down the motor with an additional fan, just for fun 😀

Why not, just for fun, and let us know how do you've added the FAN and the results.

I've taken the 5V power for the fan from the filament sensor 😉

Cheers, Simon

Re: PLA Filament problem - extruder stops extruding filament

Hi All,

I just realized that I may have the same issue as described here

Is there already some proven solution to this problem?

Many Thanks

Lukash