PLA 850/870

Hello,

I have got some spools of PLA 3D850 and 3D870 from SAKATA 3D. These materials are formulated by Natureworks.

My experience at the beginning was very bad due to following the printing instruction from the manufacturer, the MK3S got clog continuously.

After some investigations and with the help of the SAKATA support team, It's seen to be that the issue comes from the configuration (hardware and software) of the extruder of the MK3S. The reason is that in other printers like Ender, Ultimaker or Volumic (I have tested the filament on these ones) work without problem at 210ºC (specification says that working temp. between 205ºC-225ºC).

But in the MK3S I have to set the temperature to 230ºC, and the print process works. I cannot never set the first layer speed under 25mm/s. In opposite case the extruder get clog.

Obviously these PLAs composition are different, they are a little bit hard compared with Prusa PLAs.

For you information I have used these parameters:

Nozzle temp. (All layers): 230ºC

Bed temp.: 1st layer= 65ºC, The rest layers= 50ºC

Retractions: Distance = 0.7mm, Speed=30mm/s

Accelerations: Infill= 1600mm/s, Perimeters= 1600mm/s, Top/Bottom= 1000mm/s, 1st layer= 1000mm/s

I hope this can help people with try to print this kind of materials, but I would like that you share your experiences.

RE: PLA 850/870

I have never had chance to work with those filaments

Which Slicer are you using?

Prusa Slicer?

are you in advanced or expert mode? there are more variables to try.

for PLA I usually turn retraction down to 0.4mm and Z lift to 0.4mm, I generally use heatbed at 70c for all layers... and generally extruder 215 / 210 temperature!

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: PLA 850/870

@boltian

Thanks for sharing. It's always a good idea to print temp tower if you're using a new filament. Comparing print temperatures between different printers is not meaningful. Different extruder designs will always be different.

@joantabb

This looks like HTPLA filament. Usually it need to be printed with higher temp.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: PLA 850/870

@joantabb

I have used PrusaSlicer 2.1.1 and Cura. In both cases the clog appears in constant movement, eg: when fill the first layer of a 150mm x 80mm rectangle. In my case, I think that it is not problem with the retractions, it's due to deposition rate which is very bad if I set the temperature between 205-215. But in any case i will try with the proposal parameters by you.

@nikolai-r

You are right and I agree with you. Maybe, the Prusa I+D team should study this topic and prepare specific profiles for this kind of materials (HTPLAs) in PrusaSlicer. They knows perfectly the configuration of the extruder and the firmware which manage it, so they can detect very quickly the correct configuration.

I have seen in this forums a post ( https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-how-do-i-print-this-printing-help/problem-with-3d850-pla-filament/ ) where there are people with the same troubles.

RE: PLA 850/870

If you don't have an MMU2, nor plan on having one you may want to consider changing from the Prusa modified heatbreak to a stock E3D heatbreak. See this for more details:

I've heard that some people with MMU2 units also doing this successfully, but I don't remember any details so take it as a rumor.

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: PLA 850/870

@sembazuru

Thank you very much. That is the issue. After a lot of test with infinity configurations, I decided to change the heatbreak by the original version from E3D, and in this case, I have replaced the Prusa version to the titanium version. And the results..., no more clogs or jams with this kind of materials.

I have tested the material at 215ºC and 0.4mm of retractions. Worked fine, but at some prints, I got clogs.

Now, I print to 210ºC using the standard Prusa profile without any issues. Before, for me was it impossible to print to this temperature.

RE: PLA 850/870

Cant pot I get 403 wordpress error ?

RE: PLA 850/870

Cant pot I get 403 wordpress error ? vpost to long?

I am playing with this material also. I had no Jam but if i do to much retraction it will not extrude properly and sometime after a print the extruder would be clicking and wont start unless I unload and cut filament (big bulge at the end) . I was experiencing those kind of trouble since I had a clog with Glow in the dark and needed to change nozzle (replace by a cheep one and forgot it was there still) So i order a Nozzle X from E3d work great once it was temp calibrated .

I was able to print normally since then even big retraction part. But this 3D850 form Ingeo PLA fail to do those High retraction part, as I am trying to make a filament profile I decided to do the Heat break replacement for a standard E3D Titanium, even if my profile still need tuning I can Finish those High retraction pieces. I did an extrusion calibration cube , now my last layer look bad like it as to much material in the filled part... I am using , 212 c Nozzle(215 first), 65 c Bed and the prusament profile.

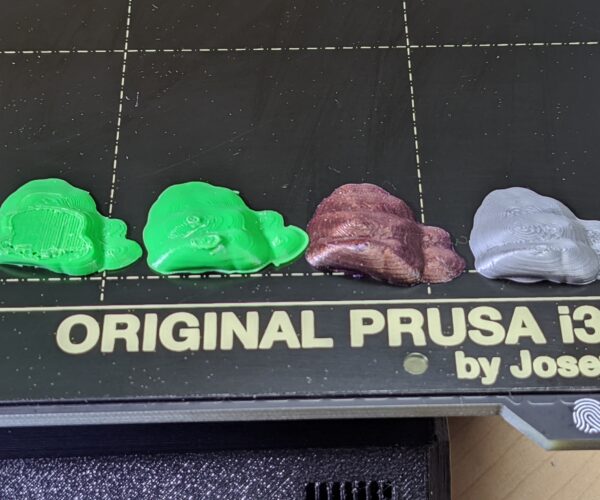

First green= Before Heat break, the top was all crumbly, Second green after with same parameter, 3 Mystic red before heatbreak with Nozzle X, Grey same thing The extrusion factor is at 1.04 I will try to lower it a bit, the bad part was a Carabiner with almost only wall so no place to push any material down...

But typing this I just realised I calibrated at 0.200 and the carabiner printed at 0.3 could it make a difference? I guess so... Ill send a Calibration cube at .300 to find out. its aiming for 1.14/2 = 0.57 I had a avg of 0.603mm

I printed a cap that has those filament like badly fuse? They look bigger then string, so do I might need more heat, I will try 215c/65c If anyone from Prusa Research Team see this, feel free to do a blog or video on the way you proceed to do a filament profile/calibration that would be awesome and very instructive!!! Stay safe!

RE: PLA 850/870

Hello,

I have got some spools of PLA 3D850 and 3D870 from SAKATA 3D. These materials are formulated by Natureworks.

My experience at the beginning was very bad due to following the printing instruction from the manufacturer, the MK3S got clog continuously.After some investigations and with the help of the SAKATA support team, It's seen to be that the issue comes from the configuration (hardware and software) of the extruder of the MK3S. The reason is that in other printers like Ender, Ultimaker or Volumic (I have tested the filament on these ones) work without problem at 210ºC (specification says that working temp. between 205ºC-225ºC).

But in the MK3S I have to set the temperature to 230ºC, and the print process works. I cannot never set the first layer speed under 25mm/s. In opposite case the extruder get clog.

Obviously these PLAs composition are different, they are a little bit hard compared with Prusa PLAs.

For you information I have used these parameters:

Nozzle temp. (All layers): 230ºC

Bed temp.: 1st layer= 65ºC, The rest layers= 50ºC

Retractions: Distance = 0.7mm, Speed=30mm/s

Accelerations: Infill= 1600mm/s, Perimeters= 1600mm/s, Top/Bottom= 1000mm/s, 1st layer= 1000mm/sI hope this can help people with try to print this kind of materials, but I would like that you share your experiences.

thank-you so much!!!... 230 was the answer... I also reduced the fan speed and made a huge diference... the rest of your settings don't make a lot of sense to me as I am not that detailed. I use the live tuning setting more.. my flow rate is 100, speed 100, nozzle 230, bed 60/40... and fan 150... is working beautifully now with the stock heatsinc

RE: PLA 850/870

Thank you! This was the most complicated filament to get right. Shouldn't the company Sakata have better instructions?