MK3S+ having hotend issues with Prusament ASA

Been marathon printing ASA this week, started noticing the surface finish of my prints slowly getting worse and worse over the last day or so. Following the craptastic quality of the latest print I pulled the filament to find a small sleeve of ASA started propagating back up the PTFE tube. This is the second time it's happened to me, first time required a full hotend tear-down, but I was lucky enough to extract it this time.

Any thoughts on what could be causing this and how to prevent it? I'm using a 0.25mm nozzle on a stock V6 hotend and have been letting everything cool down completely between prints.

Best Answer by --:

@mobious

Change your heat break ...

Though, some have found simply disassembling the hot end and adding a high quality thermal paste (renewing the cheap stuff Prusa applied) will also solve the issue.

I had to change to the stock E3D-V6 to get my printer working again. Honestly can't say it was because the old break was suffering dry thermal paste, but I have far more hours on my printer now that when I changed out the Prusa heat break, so I don't think my problem was only the paste.

ps; if you have ever changed your nozzle - it is also likely you've moved where the heat break sits in the heater block - and simply correcting that error may get you back to printing. But even in that case, new heat sink compound is worth the effort.

RE: MK3S+ having hotend issues with Prusament ASA

@mobious

Change your heat break ...

Though, some have found simply disassembling the hot end and adding a high quality thermal paste (renewing the cheap stuff Prusa applied) will also solve the issue.

I had to change to the stock E3D-V6 to get my printer working again. Honestly can't say it was because the old break was suffering dry thermal paste, but I have far more hours on my printer now that when I changed out the Prusa heat break, so I don't think my problem was only the paste.

ps; if you have ever changed your nozzle - it is also likely you've moved where the heat break sits in the heater block - and simply correcting that error may get you back to printing. But even in that case, new heat sink compound is worth the effort.

RE: MK3S+ having hotend issues with Prusament ASA

@tim-2

Thanks for the reply! Regarding the thermal paste application, would this be applied to the heatbreak threads, almost like thread locker? I have unthreaded the heatbreak/heatsink assembly from the heater block in the past, so I wouldn't be surprised if that's the issue. Any recommendations for compound to use?

RE: MK3S+ having hotend issues with Prusament ASA

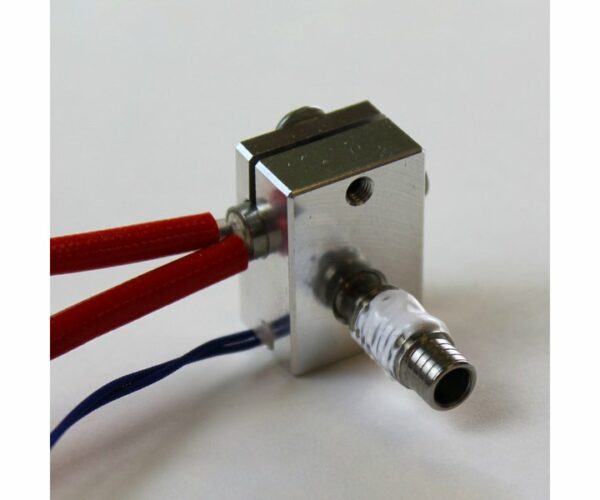

thermal paste goes on the 7mm threadded section of the heatbreak that goes into the aluminium heatsink.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK