Mk3s+ Getting Ninjaflex to work?

Hi guys,

I just completed my Mk3s+ build a couple of days ago. I've had a few successful PLA prints and decided I wanted to try some ninja flex Snow White.

I've got good experience with other printers using PLA and a stiffer TPU, but nothing as soft as Ninjaflex. I'm struggling to even get the filament loaded sometimes! What seems to happen is that when I load the filament, I can use the menus to move the E axis and extrude just fine for 50mm or so of filament; But then the extruder gears continue to turn, but the filament sticks - with no material coming out of the nozzle.

I cannot see anything wrong from the outside, but the gears are turning and the filament is not being drawn in. If I back out the E axis, the filament is generally ejected ok (But sometimes needs a bit of a pull to get it to "bite" on the gears and come out)

I've tried the following profile to do a print:

https://www.prusaprinters.org/prints/12586-ninjaflex-profile-zero-stringing-flawless-print-be

However it stopped extruding after about 20mm Z height.

If I just heat up the nozzle though, and then move the E axis, it generally stops extruding at some point - so I don't think the profile is the issue. It seems to be that the gears stop driving the filament, perhaps because they cut it to a smaller diameter that they then cannot grip?

It's a Mk3s+ with a 0.4mm nozzle and Ninjaflex Snow White 1.75mm filament. I've tried the extruder gear tension at what I thought the manual said to set during build, again at a very loose setting (just after the screw bites and engages the spring) and also at a pretty damn tight setting.

The loose setting seemed to be the best, allowing me to start a print; But it still failed after 30 minutes or so at 237c print temp, as per the profile I posted.

Any tips anyone can give? I'd love to get this filament going but it just seems to crap out randomly 🙁

RE: Mk3s+ Getting Ninjaflex to work?

When I print with NinjaFlex the filament tension screw has to be turned two times out to lighten the tension. If not, the soft filament will be flattened and prevent it entering the PTFE tube in the hot end.

Have a look at my models on Printables.com 😉

RE: Mk3s+ Getting Ninjaflex to work?

@area51

Thanks for the tip...

What Im finding is that the filament does go all the way through to the hot end, as I do see material extruded. However, I only get about 100mm of filament extruded before it seems to just block up, and then the gears no longer seem to drive the filament into the hot end and I get no material extruded.

Oddly, this seems to happen more quickly the tighter the extruder gear screw is - but the problem seems to be the extruder gears not gripping the filament properly which seems the opposite of what I'd expect.

It seems Ninjaflex needs less tension on the extruder gears, so I guess I'll just persist with it a bit at lighter extruder tensions and see what happens. Perhaps my printer needs to "break in" a bit or something before it can easily print flex...

RE: Mk3s+ Getting Ninjaflex to work?

Be sure the extruder gears are clean with no debris in the teeth.

NinjaFlex like to be extruded with constant feed at a very slow rate and without retractions. Many retractions will make the filament stuck and stop extrusion.

There is no NinjaFlex profile for MK3, but one of the other flex profiles can be used like: FillaFlex 40, Flexfill 92A or Generic Flex. Max Volumetric speed has to be low (Advanced setting).

Have a look at my models on Printables.com 😉

RE: Mk3s+ Getting Ninjaflex to work?

@delarado

I print flex filaments on my Mk3 and Mk3s all the time, both printers print them flawlessly, I have three (one at work) they are all stock. I print Ninjatek products: Ninjaflex, cheetah and armadillo on them all the time (as well as other brands) without issue. I'm using a standard brass 0.4 nozzle most of the time, but sometimes I go larger. I normally print on smooth PEI (Just because) Textured sheets work fine also, and I use a thin layer of glue stick as a separator.

My layer height may be between 0.15 - 0.3 depending on the model, however (0.2 is a great place to start for flex). I always use the "Semiflex or Flexfill 98A" this profile is a great place to start. In this standard profile I change the bed temp to 40c (frankly it could be turned off) and the nozzle to 230c, (YMMV) for me I have found that these temps work with every brand and durometer/shore of flexible filament that I've tried to date.

When using the "Semiflex or Flexfill 98A" profile in newer versions of slicer you will find that your max volumetric speed is 1.35, in older versions it was 1.5 these are both good ranges with which to run your prints when your first starting out with flex. Just forget any thoughts of speed or the word "fast" from your brain, just forget about it. leave the Max Volumetric speed at default don't change anything else other then the aforementioned nozzle and bed temps.

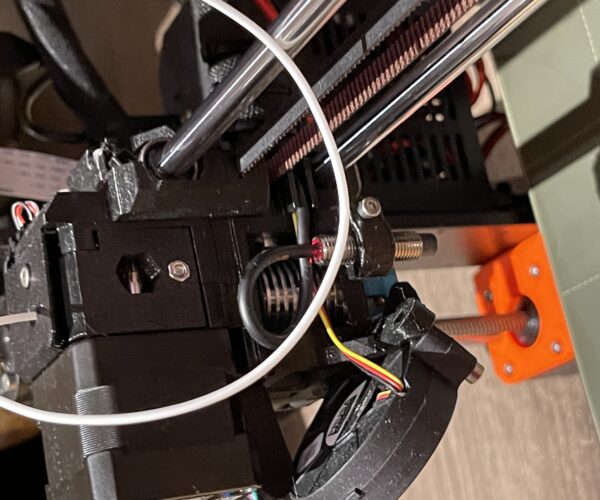

Now for the physical part, to start with you should loosen your idler screw on the MK3s, and screws on the MK3 to the point that they allow you to feed your filament into the extruder by hand while pressing in on the idler tension screw, leaving just enough room for the filament to pass (better to loose to start then to tight), feed it until you see it coming out the nozzle (of course) feed it in gently, till just before you feel it bending as you push it in. Keep the wrench handy you'll most likely need it again.

Note: you can use the auto load feature with success once you get a good idea of how to handle printing these filaments for now just stick with Manual loading.

once loaded let it sit for a minute and ooze out until it stops, you should have some type of print ready. I'm going to recommend that you start with something like a 10cm X 10cm square, your first layer will print very slowly and it will give you a chance to do the next step.

Get your print and start it, as soon as your printer starts printing keep your eye on the bondtech gears, looking in the window to see if your filament is starting to kick out of the side, if it is, it means that you have your idler tension to high, loosen the gears more and try again. I normally work in 1/4 turn increments until adjusted properly.

Conversely, if the filament is not coming out of the extruder then tighten the idler a 1/4 turn at a time giving it a second to see if its extruding after each attempt. I'm going to recommend that you start loose to the point that its probably not going to extrude, and work your way towards extrusion, rather then starting off possibly to tight and having to stop the print and clean out the gears. This is why I recommend a large flat square.

Once you feel like you have a good extrusion going on and your first layer looks nice, try printing it again from the start and see how the full print goes, always keeping an eye on the bondtech gears until your sure you got it.

Note: it can happen that your tension is just the tiniest bit to tight, and a back pressure will build very slowly causing the filament to eventually kick out of the side several layers into a print, it should go without saying, but you need to loosen the Idler a bit if this happens. {not rebuild your printer}

Once the tension is set I normally don't even have to change it between filament types, it tends to work for all e.g. PLA, ABS, PETG, ASA etc,, on occasion if I do need to tighten or loosen, it's normally not more then a 1/4 turn and in extreme cases a 1/2 turn of the idler screw. This process takes me about 5 minutes on average, if for some reason I had to open the idler door and reset the tension on the bondtech gears, I've gotten pretty good at it, and sometimes only use a small circle to make sure it's right.

You should expect it to take some time to get a handle on printing flexibles start out with higher durometer filaments they are a bit easier.

Do yourself a favor and make sure your printer is ready to go (well tuned) clean nozzle etc,, if your still having trouble printing PLA and PETG then maybe hold off on flexible's for a bit till you get the basics down.

I would get rid of any settings you changed from that downloaded profile you mentioned.

Anyway this is my experience, maybe it will help.

Enjoy and good luck

The Filament Whisperer

RE: Mk3s+ Getting Ninjaflex to work?

@swiss_cheese

Thanks dude for the in depth info. I've tried running my extruder as low on the tension as I can (Just after the screw bites) I'm not sure I can really go much looser...

I Can print PLA and PETG perfectly with zero issues. I'm wondering if my Ninjaflex is a bit wet or something. Just running a 6 hour print for a raspberry Pi case - I'm going to throw the Ninjaflex in a dryer while that completes and try again later with the default Prusa profiles.

Will let you know how I get on. Thanks for the input all!

RE: Mk3s+ Getting Ninjaflex to work?

@delarado

Your welcome,

I'm interested to know how it goes for you, Have you printed other flexibles successfully before? or is this your first time trying them?

The Filament Whisperer

RE: Mk3s+ Getting Ninjaflex to work?

@delarado

Your welcome,

I'm interested to know how it goes for you, Have you printed other flexibles successfully before? or is this your first time trying them?

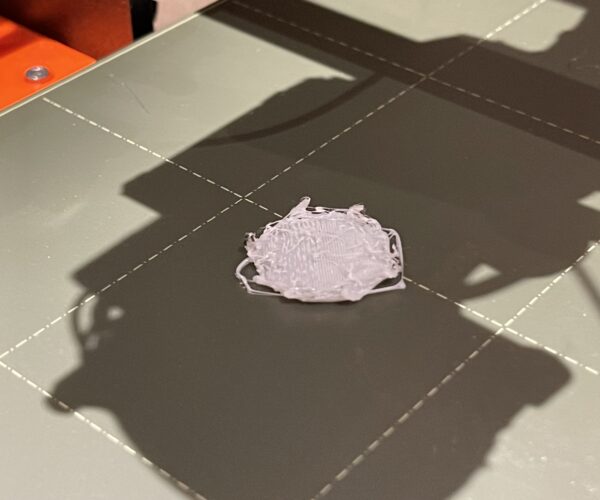

This is my first time trying Ninjaflex. I have a much less flexible TPU filament that prints OK, but Ninjaflex simply does not work for me. I tried it again yesterday... The results are attached.

I went for no retraction this time (I found it was still enabled by accident) and went for a maximum print speed of 10mm/s. I still have the exact same issue...It kind of works "ok" For a little while, but then the filament just stops extruding. The hot end was 3mm or so above the pictured mess, still acting like it was printing - but nothing coming out. It doesn't come out of the side of the hot end, its like the gears just lose grip on the filament and cannot drive it forward any more.

At this moment it won't extrude or retract. The gears j ust spin. But if I pull the filament a bit, it starts to retract ok where the gears bite.

I've attached the GCODE if anyone wants to have a look. I don't know where to go with this now...

RE: Mk3s+ Getting Ninjaflex to work?

unfortunately really can't look at your settings with a g-code, can you post a ziped up .3MF file

The Filament Whisperer

RE: Mk3s+ Getting Ninjaflex to work?

Heres the 3MF, I've disabled retraction with the filament override and set max print speed to 20mm/s...

RE: Mk3s+ Getting Ninjaflex to work?

I'd like to say after a lot of trial and error and scouring the web, I have dialed in my ninjaflex settings.

A BIG help was 2.3.0 prusaslicer to cut down on the stringing by avoiding the crossing of perimeters.

Let me know if you want my .3mf file for specific settings.

RE: Mk3s+ Getting Ninjaflex to work?

RE: Mk3s+ Getting Ninjaflex to work?

Ok learned from my mistake. Here's the zipped .3mf file of my dialed in Ninjaflex settings.

RE: Mk3s+ Getting Ninjaflex to work?

Here's the result.

RE: Mk3s+ Getting Ninjaflex to work?

That is about as good as you can expect.

--------------------

Chuck H

3D Printer Review Blog

RE: Mk3s+ Getting Ninjaflex to work?

@cwbullet

It was a journey.... a few days of frustration. I have good settings of PolyFlex TPU95a as well. Given how much config there is for each vendor+material, I've decided to start weeding out the 17 or so spools of different filament I have and pick one vendor for each type and get those settings dialed in.

For the TPU I think the NinjaFlex is now my go to. The PolyFlex does work ok though.

For PLA and PETG I'm trying to do the Paramount3D unless there's some specific color I want. I think this will get me more reliable prints and less dorking around with configuring for some new filament I've not printed with.

RE: Mk3s+ Getting Ninjaflex to work?

@delarado

Did you ever get this figured out?

RE: Mk3s+ Getting Ninjaflex to work?

@ssill2

Your grasping at straws.

The Filament Whisperer

RE: Mk3s+ Getting Ninjaflex to work?

In the US, I would also recommend California Filaments and Fusion Filaments for PETG.

--------------------

Chuck H

3D Printer Review Blog

RE: Mk3s+ Getting Ninjaflex to work?

@swiss_cheese

How so?