Micro-Howto: Filaflex 82A my first print

Tonight I started printing flexible. Here a micro Howto on printing with filaflex 82A on a 3s.

At first: Read all articles you can find on printing with flexible material and consider them before trusting me.

At Second: Be sure your printer operates with materials like PLA or PET perfectly. Compare to others to get a picture.

At Third: Prepare your printing area to avoid the really adhesive material to glue on it. I used the Prusa Gluestick. It worked but it may be not the solution for larger prints.

I used Filaflex 82A from from Recreus (was a good buy).

Downloaded the Recreus Sliz3r parameter files. I utilize Linux - files or paths may differ.

Created/Added in ~/.PrusaSlicer/filament/Filaflex.ini the part of the Recreaus-Sli3r file dealing with filament:

bed_temperature = 0

bridge_fan_speed = 100

cooling = 1

disable_fan_first_layers = 2

extrusion_multiplier = 1.05

fan_always_on = 0

fan_below_layer_time = 60

filament_colour = #FFFFFF

filament_diameter = 1.75

first_layer_bed_temperature = 0

first_layer_temperature = 240

max_fan_speed = 100

min_fan_speed = 100

min_print_speed = 20

slowdown_below_layer_time = 5

temperature = 235

This new filament has to be registered in ~/.PrusaSlicer/PrusaSlicer.ini in the section [filaments]

[filaments]

ColorFabb HT = 1

ColorFabb PLA-PHA = 1

ColorFabb XT = 1

ColorFabb XT-CF20 = 1

ColorFabb bronzeFill = 1

ColorFabb copperFill = 1

ColorFabb corkFill = 1

ColorFabb nGen = 1

ColorFabb nGen flex = 1

ColorFabb steelFill = 1

ColorFabb woodFill = 1

E3D Edge = 1

E3D PC-ABS = 1

Filaflex = 1

....

Then I restarted the Prusa-Slizer.

A new print got me the possibility to choose "Filaflex" for the filament.

THIS IS IMPORTANT!

Under Printer-Settings (Expert Mode) I set all printing velocities to 15mm/sec.

I choose "0.15 Quality" and "Origional Prusa iS MK3S"

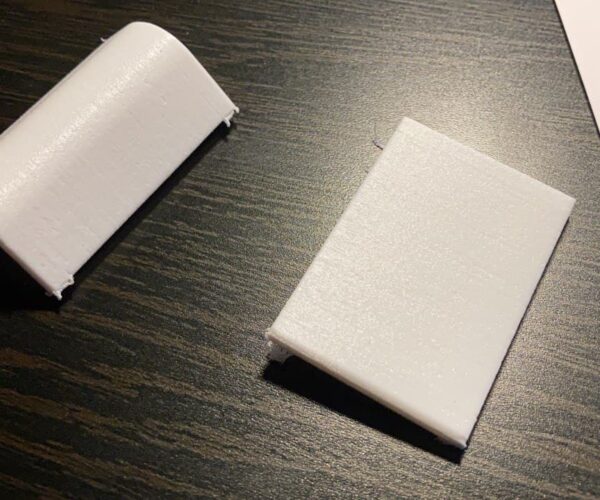

Then I printed and the outcome was really good.

Not the perfect solution, but it works.

Cheers,

Volker

RE: Micro-Howto: Filaflex 82A my first print

Hi there, thanks for the tips.

I'm about to print with the same filament, too.

I was curious about why you chose the 0.15 Quality, instead of the FilaFlex profile.

I will also try to disable the retraction as many have suggested, any thoughts about that?

Daniele

RE: Micro-Howto: Filaflex 82A my first print

@dsgn-dv

I chose the 0.15 Quality AND the filaflex Profile.

Without retraction you will have a terrible amount of stringing. You will have a bit of stringing in any case, but without retraction it will be worse.

If you print a bunch of objects in one run it may be a good idea to use the print setting for "print objects seperately". "Output-Options" -> "Sequential printing" -> "Compatible single objects". I put these words in quotes since I have a german UI and have to guess the correct terms in english. It is a bit of struggle to position the objects correctly, but the outcome prove it is worth.

And be really carefull with the preparation of the heatbed. You will need a good anti glue material to seperate the frist layer from the heatbed. The glue pen from Prusa works quite good. Important is to coat all of the surface where you will print AND the initial line as well.

Happy printing

Volker

RE: Micro-Howto: Filaflex 82A my first print

@volker-jaenisch

Hey Im trying to print with this filament as well, but can not download the Filaflex parameter settings that you linked. Im in Windows - dont know if this is causing the problem?

Do you still have it on your computer? If so, do you mind attaching it? 🙂 Could be awesome!

Best Regards

Jonathan

RE: Micro-Howto: Filaflex 82A my first print

@jonathan-2

The link in my former post is broken. Points to google drive (where Recreus stupidly put their paramter files) and something changed there.

The following link is a copy of the files I downloaded some time ago.

FILAFLEX SLICER SOFTWARE PROFILES

And this is the link to the filament at Recreus website.

https://recreus.com/en/producto/82a-filaflex-500gr/

There you find in the technical data section the link to google drive

https://drive.google.com/drive/folders/1SPinL6AZkqXufr20_AnGH36V9R0J5RGp

wich will also surely not last long. But it may contain a fresher version than my attached ZIP-File.

Happy Printing and don't forget to coat your printing sheet!

Volker

RE: Micro-Howto: Filaflex 82A my first print

Hi Volker!

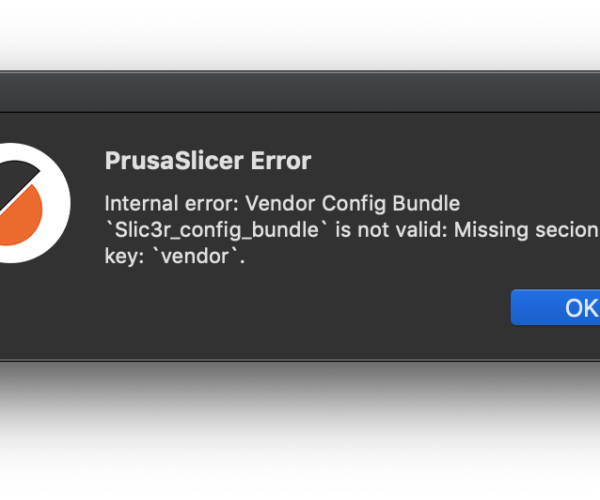

I just tried importing the profile for my Filaflex 82A as you described it (working on Mac), but after I saved the downloaded file (Slic3r_config_bundle.ini) into the "profiles" folder, PrusaSlicer gave me the following error message after trying to add a new filament:

PrusaSlicer Error

Internal error: Vendor Config Bundle `Slic3r_config_bundle` is not valid: Missing secion or key: `vendor`.

Did you have the same issue and how did you go past it?

Thanks and best regards,

Benjamin

RE: Micro-Howto: Filaflex 82A my first print

Have to put the file in the folder "filament"?

RE: Micro-Howto: Filaflex 82A my first print

@volker-jaenisch

Yes, thanks, I just found it. I was looking in the package contents, but the actual folder was in Library -> Application Support -> PrusaSlicer.

Thanks for your blog entry!

RE: Micro-Howto: Filaflex 82A my first print

Hello everyone.

I just managed to print with the Filaflex 70A a couple of times as well, same settings suggested by Volker but without retraction.

HOWEVER the feeding here is painful. I'd like to try with the + upgrade of the extruder, as I failed multiple times to properly feed the filament inside the PTFE tube. Let me tell you, that wasn't nice.

You should also consider to have enough space between nozzle and bed for the material to flow out instead of pushing in the opposite direction: raise quite a bit the Z in the live adjust.

If you have additional tips and you ever going to try this, let me know.

Cheers

video showing how flexible it is

Maximum volumetric speed

Hi @volker-jaenisch

Thank you for this post!

Please, tell me which was the value set for Maximum volumetric speed setting (MVS) for Filaflex 82A

Thank you!

Tonight I started printing flexible. Here a micro Howto on printing with filaflex 82A on a 3s.

At first: Read all articles you can find on printing with flexible material and consider them before trusting me.

At Second: Be sure your printer operates with materials like PLA or PET perfectly. Compare to others to get a picture.

At Third: Prepare your printing area to avoid the really adhesive material to glue on it. I used the Prusa Gluestick. It worked but it may be not the solution for larger prints.

I used Filaflex 82A from from Recreus (was a good buy).

Downloaded the Recreus Sliz3r parameter files. I utilize Linux - files or paths may differ.

Created/Added in ~/.PrusaSlicer/filament/Filaflex.ini the part of the Recreaus-Sli3r file dealing with filament:

bed_temperature = 0

bridge_fan_speed = 100

cooling = 1

disable_fan_first_layers = 2

extrusion_multiplier = 1.05

fan_always_on = 0

fan_below_layer_time = 60

filament_colour = #FFFFFF

filament_diameter = 1.75

first_layer_bed_temperature = 0

first_layer_temperature = 240

max_fan_speed = 100

min_fan_speed = 100

min_print_speed = 20

slowdown_below_layer_time = 5

temperature = 235This new filament has to be registered in ~/.PrusaSlicer/PrusaSlicer.ini in the section [filaments]

[filaments]

ColorFabb HT = 1

ColorFabb PLA-PHA = 1

ColorFabb XT = 1

ColorFabb XT-CF20 = 1

ColorFabb bronzeFill = 1

ColorFabb copperFill = 1

ColorFabb corkFill = 1

ColorFabb nGen = 1

ColorFabb nGen flex = 1

ColorFabb steelFill = 1

ColorFabb woodFill = 1

E3D Edge = 1

E3D PC-ABS = 1

Filaflex = 1

....Then I restarted the Prusa-Slizer.

A new print got me the possibility to choose "Filaflex" for the filament.

THIS IS IMPORTANT!

Under Printer-Settings (Expert Mode) I set all printing velocities to 15mm/sec.

I choose "0.15 Quality" and "Origional Prusa iS MK3S"

Then I printed and the outcome was really good.

Not the perfect solution, but it works.

Cheers,

Volker

all metal hotend?

@Daniele

What kind of extruder/hotend were you using with the 70A? Did you have success with the all metal hotend?

I only feeds 1-2cm, then it stucks on my Bondtech BMG with an all metal hotend (RS-Präzision titan heatbreak).

Kai