Issue with PLA

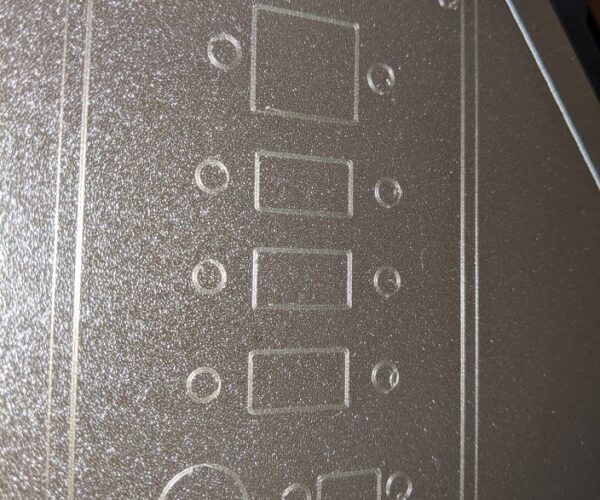

I had good luck with printing with the PLA that came with my MK3s. Now that it's all gone, I switched to Prusament PLA, Pearl Mouse. I used all of the default settings in PrusaSlicer, and I'm seeing this. I'm not sure if you call this "stringing", or something else. Any ideas? Thank you.

RE: Issue with PLA

Looks like poor adhesion. It also looks like a textured bed. So it looks like you are on cleaning duty or buying a smooth sheet. Soap, water and good scrub with a soft scouring pad will clean the sheet. Dry and final degrease with IPA. This applies to smooth sheet too but if you are happy with textured bed then pages 16 & 17 in the 3D printing handbook will give you pointers.

It's also worth noting that PLA is a generic term and that the "mix" can vary not only between manufacturers but also with differing colours from the same manufacturer so your earlier success may have been luck.

Hope that helps.

Andrew

p.s. If you take the time now and let the your partner see you draw little dotted lines on the textured plate they will never know you bought a new smooth one.....tee hee

AD

RE: Issue with PLA

@andrewld

Thank you Andrew. I was doing some more research on this forum and wondered if it could be something with extrusion or retraction, since it seems to be more of an issue on the "starts" and "stops" for each feature.

I performed the extrusion test with the small cube and it was spot-on without any adjustment requirement. Today, I will try to see if it is an issue with the idler door tension.

If that fails, should I play with any of the retraction settings in PrusaSlicer? I will also of course do as you suggest and give my textured sheet a good cleaning.

RE: Issue with PLA

Play away but only change one thing at a time. More than that and you will never know the cause/cure. There does look to be a fair bit of blobbing at the turns so I would check the nozzle hasn't got goop stuck to it perhaps from (as you note stringing/retraction) getting caught on the nozzle. If you haven't already done so do a layer test on more than just the first layer. You may be a tad low on Z for this filament and the nozzle is picking up filament as it goes round. I mention this as that's one of the many many things I got wrong....tee hee.

Best of luck

RE: Issue with PLA

@andrewld

Thanks, I will try one thing at a time. And also look at z-height for this filament.

I went online to the Prusa shop but unfortunately the smooth sheets are out of stock right now. Hopefully they'll be back in stock soon!

RE: Issue with PLA

Ok, so an update of things that I tried today.

First, I adjusted my idler door tension based on the Prusa video.

Next, I adjusted my PINDA probe and re-calibrated. My old live-Z value was around -1.55. My new live-Z value is right at -0.950.

Then, I cleaned my textured sheet with soap/water, and a final wipe with IPA.

I then tried to print again. You can see that it is much improved, however, it is not completely fixed. There are still blobs right at the beginning of each feature, when the nozzle touches down. So, next thing that I did was switch to another brand of PLA - Overture. And it worked 100%, no problems.

So, it's definitely related to the Prusament Pearl Mouse requiring different settings, although I do not know what those are. Could anyone recommend what might be causing the small blobs right at the start of each feature? Still an adhesion issue, or something else?

RE: Issue with PLA

Sticking with one thing at a time.

I'm going to go with with stringy blobby filament. Some are more forgiving than others. So I'm afraid its twiddle and poke until you get to the happyland with this filament. Others with vastly more experience than me could give you the best order to round the houses but you want to look at the causes;

Retraction - reduce the amount coming out by increasing the retraction value. This will "suck up" some material so you don't get the blobs from extrusion continuing whilst moving from A to B.

Speed during moves - increasing this can reduce the amount of time the filament has to "drip" from the nozzle whilst moving however go too fast and the finish will suffer as the hot end still has a fair bit of inertia wanting it to keep going where it was heading.

Temperature - again if the filament is very molten it will extrude more simply from the pressure built up in the hot end than if it is a little cooler. So reducing the temperature can help, but again go too far and it wont print well.

I'm sorry no one of the above is THE answer as all 3 impact on the performance. If you have a look in the forum under that specific filament type you will see a recent post with the same issues. I followed for a while trying to learn stuff but it may have got to a decent conclusion.....or a different filament...

Andrew

Can you create a model that recreates the issue (moves) but prints really quickly or are you happy to continue with this one?