Funnel print dragging string across

I got a 3D printer for the first time this week. I have never done CAD before.

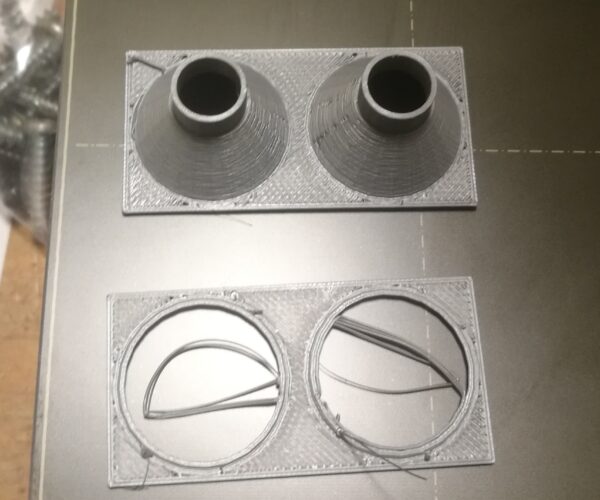

I've printed a couple of bits that came out well but I'm having problems with this funnel. I have printed a single unit of it with no problems (the first print, but I didn't save the gcode) but now I've combined two together, it's pulling a string across the circle.

You can see a picture of the problem, and the gcode and the STL here.

https://www.prusaprinters.org/prints/77718-double-funnel-tray

When I watch the hotend, it seems like the print is not sticking to the layer below it.

Can someone teach me please:

- Is this called "stringing"?

- Should I be using support material, would that prevent it? Considering it's a conical shape, how would I disconnect it?

- Is there a way to prevent this without support material? I tried reducing the speed of printing outer perimeters to 10mm/s (from 25) but this didn't help.

Best Answer by JoanTabb:

I got a 3D printer for the first time this week. I have never done CAD before.

I've printed a couple of bits that came out well but I'm having problems with this funnel. I have printed a single unit of it with no problems (the first print, but I didn't save the gcode) but now I've combined two together, it's pulling a string across the circle.

You can see a picture of the problem, and the gcode and the STL here.

https://www.prusaprinters.org/prints/77718-double-funnel-tray

When I watch the hotend, it seems like the print is not sticking to the layer below it.

Can someone teach me please:

- Is this called "stringing"?

- Should I be using support material, would that prevent it? Considering it's a conical shape, how would I disconnect it?

- Is there a way to prevent this without support material? I tried reducing the speed of printing outer perimeters to 10mm/s (from 25) but this didn't help.

it looks to me, as if you need supports

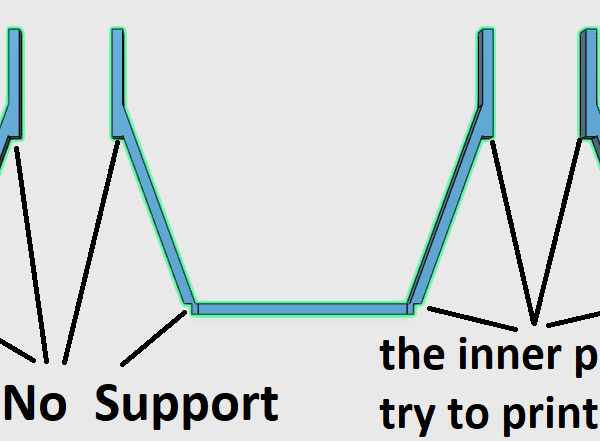

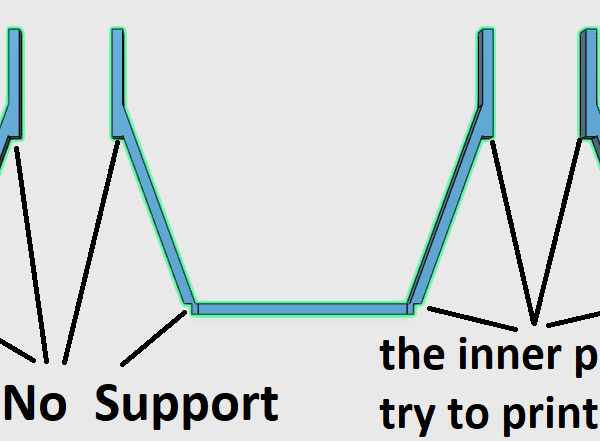

if you take a cross section of your model it will look something like this

there is no support under the horizontal portions of the funnel where indicated, so the inner perimeter will try and print in mid air

Are these horizontal surfaces necessary? if the model didn't have these surfaces, it would print without support

regards Joan

I got a 3D printer for the first time this week. I have never done CAD before.

I've printed a couple of bits that came out well but I'm having problems with this funnel. I have printed a single unit of it with no problems (the first print, but I didn't save the gcode) but now I've combined two together, it's pulling a string across the circle.

You can see a picture of the problem, and the gcode and the STL here.

https://www.prusaprinters.org/prints/77718-double-funnel-tray

When I watch the hotend, it seems like the print is not sticking to the layer below it.

Can someone teach me please:

- Is this called "stringing"?

- Should I be using support material, would that prevent it? Considering it's a conical shape, how would I disconnect it?

- Is there a way to prevent this without support material? I tried reducing the speed of printing outer perimeters to 10mm/s (from 25) but this didn't help.

it looks to me, as if you need supports

if you take a cross section of your model it will look something like this

there is no support under the horizontal portions of the funnel where indicated, so the inner perimeter will try and print in mid air

Are these horizontal surfaces necessary? if the model didn't have these surfaces, it would print without support

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

no overhangs

Hi Joan, thanks for your quick reply. Those overhangs are not necessary at all.

Does this file look better? https://www.prusaprinters.org/prints/77724-double-funnel-no-overhang

Please ignore the identical photo, I haven't tried to print it yet. Can I upload just STL files to the forum somehow?

you cannot add STL files directly to the forum,

But if you ZIP compress them first, you can add the ZIP FIle

double funnel no overhang

this file should print without the previous file's errors

double funnel no overhang_0.2mm_PLA_MK3S_23m (2)

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

May I ask, what it's for?

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

reply

Thanks Joan. It actually came up with an error when I tried to slice it at 0.3mm so I raised up the hollow cylinder and made the cone taller, and it still wouldn't slice the hollow cylinder. Switching to the 0.2mm setting allowed it to slice. Do you have any idea why that would be?

I have just set it printing so I will upload a picture.

It's for filling small bottles with sand for a product we make at work. Currently we scoop the bottles through the sand but it's not very consistent or fast. I've also 3D printed a 5.8mL scoop with matching diameter to get just the right amount, faster.

is the double funnel easier to use than a single funnel? do the bottles line up easily with the double funnel?

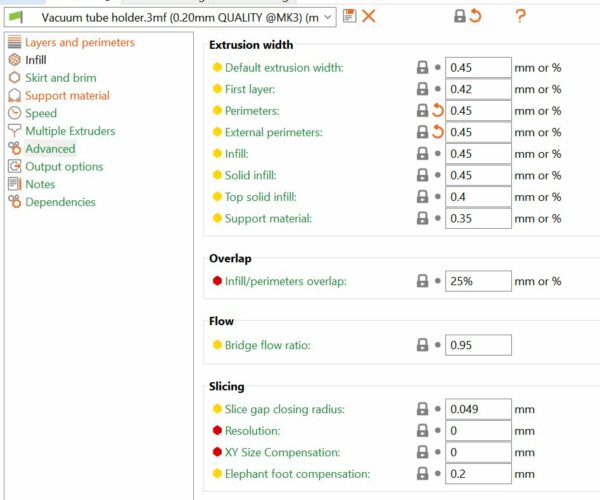

if you set the layer height to 0.3mm, the slicer sets the extrusion widths to larger values and this stops the tube at the top of the cone from being resolved... resetting the external perimeter extrusion width to 0.45 corrects the error...

the table above was from a 0.2mm layer height model, and the slicer must be in advances, or expert mode to see the table.

would you want a 0.3mm layer height? It is likely to make the surface of the funnel rougher and more likely so cause the sand granules to stick to the surface

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

funnels

Eventually my plan is to do this for a 3x8 grid of bottles, and I've designed a tray to go underneath that will guide them to ensure perfect alignment for the funnel tray. This is the prototype, and it seems to work well.

With this printed at 0.2mm layer height, it seems that the funnel is pretty smooth and the granules flow fine. For the final one, I will use a smaller layer height and let it print overnight. Thanks for the suggestion.

Great tips about increasing the extrusion width. I figured it was something like that but I didn't realise it would be possible to change it. I'm absolutely loving this so far, I am annoyed with myself for waiting for months to buy it (in case it became a toy I didn't use!)

If its for business. Is it really a toy? 🙂

Remember there are some things better not printed in plastic

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

If its for business. Is it really a toy? 🙂

Remember there are some things better not printed in plastic

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

title

Well, now I can say for sure it's a tool and not a toy. But it has taken those months to figure out something very concrete that I could use to justify buying it, everything else was just phone holders and the like. 🙂

Remember there are some things better not printed in plastic

What do you mean by this? I think the low cost of plastic makes it pretty ideal for this. Perhaps metal would be good but I think any advantage would be incremental at best.

A couple of comments , based on your last picture our first layer could do with being adjusted closer as there's too much gap between the strands. That first layer should be pretty much unbroken. Use the Jeff Jordan live adjust method as its way better than the in built procedure. https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

Secondly I think Joan was referring to the fact that most 3d printed plastics should be carefully evaluated for their intended use. For example the grooves of print layers are excellent for breeding germs and can be difficult to clean. Especially with lower temperature materials. Probably not a consideration for sand though 🙂

Addidional to neophyl's comments. Heat significantly softens pla. Some things are better in metal.

Early in experience. There is a tenancy to over estimate the capabilities of plastic

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: reply

I see. There is no heat, just pouring of sand. I also have ASA and PETG, and if it can't be done with that then I will probably think of a different solution. I'm a chemist by training, so I have pretty good understanding of the compatibility limits of materials etc but I fully expect to be learning lots of new things throughout this.

I see. There is no heat, just pouring of sand. I also have ASA and PETG, and if it can't be done with that then I will probably think of a different solution. I'm a chemist by training, so I have pretty good understanding of the compatibility limits of materials etc but I fully expect to be learning lots of new things throughout this.

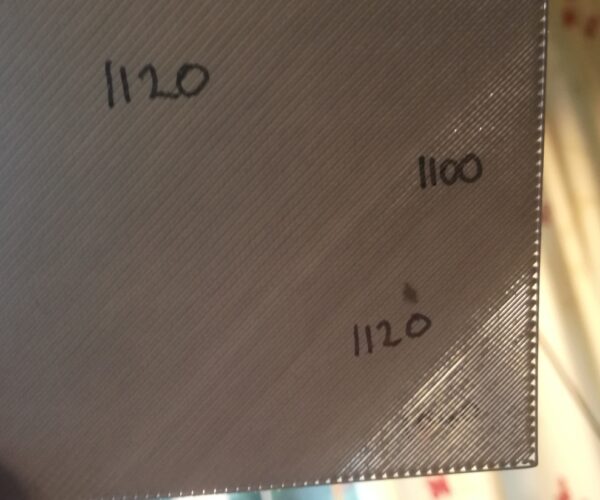

Great tip about the live Z adjustment. Bottom right was the original setting (-1.045), now it's set to -1.120 and much smoother. Thanks both for your help.

Are you using 3x3 mesh bed levelling, or 7x7 mesh bed levelling?

7x7 is available through the LCD Menu. I think it's the settings menu!

7x7 probes 49 points on the bed, where as 3x3 probes 9 points on the bed

the avoid magnets option... whatever it's called, negates 11 of the 49 probe positions to prevent the magnets affecting the results...

I always use 7x7 ...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

not to mention cost

besides the points mentioned above, cost is also a factor. prototyping something to see if it looks viable makes total sense on the 3d printer. if you're going to make a bunch of them, your best off to have something you give to a profession production company to injection mold. Injection molded parts wouldn't have the layers and thus the places bacteria could grow, and the cost per unit(depending on quantity) would be a great deal less.

reply

Now using 7x7, good tip. Thanks.

My Pleasure,

did it improve your first layer?

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK