Fillamentum Flexfill printing problem

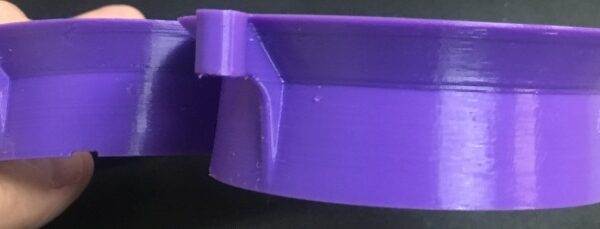

So I'm a n00b 3d printer owner, and have started printing drone parts. This model is a well used Shendrones Squirt part, and I've been having some trouble. At first, I had a lot of chunking from the printhead where I think I was printing too fast and it blocked. I dropped the print speed to 50%, and this is the first usable part, but it still has issues. What am I doing wrong and what do I need to improve?

RE: Fillamentum Flexfill printing problem

Generally folks on here are going to want you to zip up your .3mf file and attach it here so they can look at your settings.

RE: Fillamentum Flexfill printing problem

ssill2 is correct, if you could Save your project as a .3mf file from slicer, then zip it up and post it here using the ![]() button.

button.

This will allow us to see your model and all relevant settings as they pertain to it, as well as allowing us to make changes to the project and upload an adjusted version if necessary.

It is the way.

Off hand I see at least 4 things that you might want to consider changing just from your images. your model orientation is poor, you need to turn on avoid crossing perimeters, most likely adjust your extrusion width or perimeters, and possibly your temps.

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: Fillamentum Flexfill printing problem

Flexfill is an advanced printing topic. PLA is like Filament 101. PETG is 201. Flexfill is 440 level course. There will need to be a great flex profile, which involves a lot of settings, and cooling and speed.

Would not recommend starting out with Flex as your target. - there are too many things to master first. Remember, say this to yourself over and over - it's not a toaster. You can't just load a gcode and print and expect results.

RE: Fillamentum Flexfill printing problem

I have no idea why the editor chose to move to long text on one line mode above

RE: Fillamentum Flexfill printing problem

I have no idea why the editor chose to move to long text on one line mode above

Thats also an advanced topic 🤣

The Filament Whisperer

RE: Fillamentum Flexfill printing problem

I have no idea why the editor chose to move to long text on one line mode above

Thats also an advanced topic 🤣

Mr. Cheese, you made my day with that one 🤣

RE: Fillamentum Flexfill printing problem

Flexfill is an advanced printing topic. PLA is like Filament 101. PETG is 201. Flexfill is 440 level course. There will need to be a great flex profile, which involves a lot of settings, and cooling and speed.

Would not recommend starting out with Flex as your target. - there are too many things to master first. Remember, say this to yourself over and over - it's not a toaster. You can't just load a gcode and print and expect results.

100% true. Filaflex is difficult.

--------------------

Chuck H

3D Printer Review Blog

RE: Fillamentum Flexfill printing problem

@bascule

Are these supposed to be this squishy ?

I printed this with a durometer 95A TPU I had laying around, it just seems so soft like it wouldn't protect the props if it crashed hard.

Is this what people are building these out of?

Regards,

Swiss_Cheese

The Filament Whisperer

RE: Fillamentum Flexfill printing problem

Well, the OP decided to try it with flex. Me? I'd use PETG

RE: Fillamentum Flexfill printing problem

@swiss_cheese

your prints turned out pretty at least lol

RE: Fillamentum Flexfill printing problem

@swiss_cheese

your prints turned out pretty at least lol

Yes, well my woman likes purple and pink so you better believe I have some of that color around 😋

The Filament Whisperer

RE: Fillamentum Flexfill printing problem

@swiss_cheese

likewise lol

RE: Fillamentum Flexfill printing problem

@bascule

Are these supposed to be this squishy ?

Swiss_Cheese

That's a good question - I didn't question why these were printed in TPU by others everywhere on the net. They print fine in PETG. 🙂

p.s. hello from the JB discord server, IIRC. I'm that cycling fella over there. 🙂

RE: Fillamentum Flexfill printing problem

@Swiss_Cheese, pretty please with a cherry on top if you'd be willing to share your slicer file/gcode for that TPU print on a Prusa Mk3 S+ I would be super grateful. I was using 98A, btw, which is a fair bit stiffer. I think the idea is to protect people more than props given the purpose of the squirt.

RE: Fillamentum Flexfill printing problem

OK, some improvement and I have an at least functional print, if not the most perfect. The keys were to slacken off the Bondtech tension to almost the bare minimum possible, and to run the printer at 25% speed. This after setting very low flex printing of 20mm/s in Prusa Slicer.