Filament stops extruding but I can't find a clog and cold pull comes out clean.

So I've tried Prusa support for this but they keep running me through maintenance steps that completely miss my issue, so I'm turning to you guys to see if you have any ideas.

I've got an MK3 using CC3D's bronze silk filament. I've had many successful prints off this filament, but any time I try to print anything with a flat face parallel to the build plate the printer jams. I'll pull the filament out and it'll be perfectly in the shape of the nozzle just like I'd just performed a cold pull. I'll clip that off, reload the filament, it'll extrude properly and then it'll jam again within a couple minutes of going back to work on the flat area.

This problem appears to be getting worse over time, with the printer now jamming up anytime I print anything with a high infill (60% or more). It does not jam on support material, only and ever on the print itself.

I've recalibrated, tightened everything, done several cold pulls and for the life of me can't figure out what's causing the jams. Changing the temperature of the nozzle seems to have no effect either, I've tried everything between 195 and 215 and the jamming is the same every time. If anyone has some advice or input I'd appreciate it.

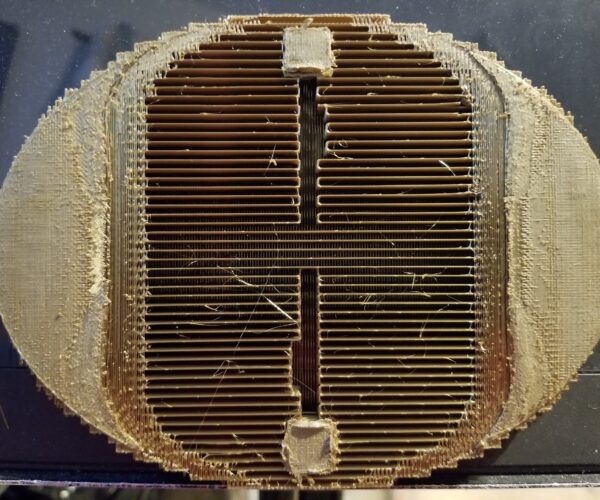

I've included a picture of my latest failed print, a large belt buckle that I've managed to print once on higher resolution with this same filament. It gets roughly this far every time before the clicking begins.

I use the Mika3d metallic silk filaments and I've had occasional jams which do not occur when I raise the nozzle temperature maybe 10 degrees C or so.

I do this by simply bumping up the temperatures in the Filament Settings tab in PS or on the Material tab in Cura.

I do this mostly with my 'other' printer, which defaults to 205 for generic PLA, but I do bump up the temp on the Prusa to 220 or so when printing with this filament.

It sounds like it has the same issues as my Filamentum Crystal Clear Iceland Blue.

With mine I came to find out that this filament is infamous for that clicking issue.

What I found works the best is to tighten my gears closer together on the extruder.

Filament stops extruding but I can't find a clog and cold pull comes out clean.

I think it is a variation in diameter. If you have a pair of calipers or Micrometers check that. ~Prusa Fanatic

I would also suggest that 60%+ infill is usually unnecessary and often counterproductive. In general, I'd rather increase the number of perimeters than going above 25%, maybe 40%, infill.

,and I'm going to ask what layer height your printing at?

The Filament Whisperer

title is required for a reply apparently

I've tried 5mm-10mm. Unfortunately cranking the heat up as the first reply suggests seems to result in a lot of print curling which catches on the extruder.

,and I'm going to ask what layer height your printing at?

layer height

Not model height, layer height, ie 0.2 or 0.1 or even 0.05 ?

oh

Sorry, I'm braindead. .05 to .1

Not model height, layer height, ie 0.2 or 0.1 or even 0.05 ?

@eurgiga

I'm going to suggest raising the layer height to 0.15, and increasing the heat as Jsw suggested, and reducing the infill as Fuchsr suggests.

Your print settings and filament type are a perfect storm for nozzle clogs.

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: Filament stops extruding but I can't find a clog and cold pull comes out clean.

I agree with swiss_cheese. With a 0.4 nozzle I can't see any difference in print quality with anything less than 0.1mm layer height, it just adds time.

Success!

Tried those suggestions and coupled it with altering the angle of the print to eliminate passing over large flat areas parallel to the build plate. Thanks for all your input!