Colorfabb PLA/PHA Failing repeatedly

Hi,

We recently purchased a Prusa I3 MK3 for the office and so far I've been very succesful with printing PLA from Prusa and MatteForge, no prolem.

But today I tried printing with Colorfabb pale Gold PLA/PHA, and every print fails at the first layer. The filament doesn't stick to the bed and gets stuck to the nozzle.

I've tried live Z adjust and changing the nozzle temperature to 220, but other than that I'm a bit lost with what's wrong. Has anyone had a similar problem?

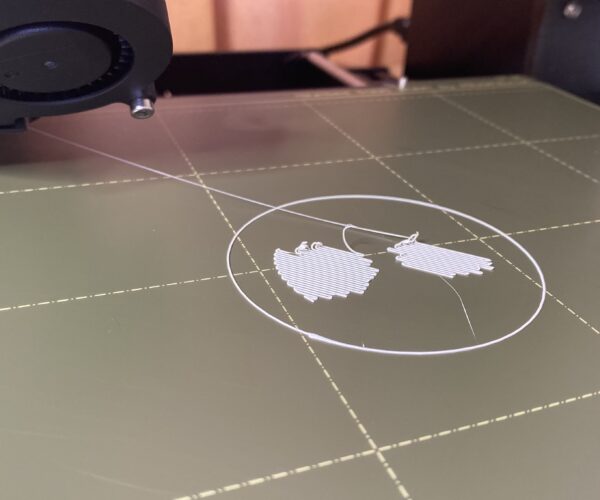

I'll attah images of the first layer if that helps.

Thank you in advance

Re: Colorfabb PLA/PHA Failing repeatedly

Also, a fourth image that didn't seem to upload with the first post

Re: Colorfabb PLA/PHA Failing repeatedly

I have the same problem with colorfabb pla and when I maintain the pressure, the quality of the exterior gives unbelievably poor performance. There is no problem in other brand pla 😕 😕 😕 😥 😥

Re: Colorfabb PLA/PHA Failing repeatedly

Same for me but I got 3 year old water damaged spools 🙁

Dried them in my oven but I get really poor prints, just one complete print so far...

215C first layer no fan

210C rest of layers and 100% fan

Even tried Volumetric E in Slic3r but nothing works, tried layer heights from 0.1 to 0.3 and all fails...

Re: Colorfabb PLA/PHA Failing repeatedly

Hello,

I experienced similar problem yesterday. I received ColorFabb black and silver PLA/PHA. I started reading specs and descriptions on the box to be sure temperature setting. I read:

"PLA/PHA is printed on most 3D Printers between 195-220C."

I thought "ok, let's get the spool from inside" and realised than on spool there is written something different:

"190/210C hbp 50C / 60C"

It was confusing so I safely assumed that I start with 200C and when everything will be ok, then I'll be using same settings as for PLA's from other manufacturers.

And I started printing...

After about half hour of first print I noticed that no filament is extruding. I stopped process, looked at the pooleys and discovered that filament has been bending and be blocked. Ok, so I thought that filament was too cold and extrusion isn't too efective. Next, I raised temp to 210C and started to printing Prusa whistle. And this was success. Right after that I also successfully printed a 100% infill calibration cube (20x20x20 mm). Next I decided to print another Prusa model - bearings. And unfortunately it wasn't ok. Extruder has been cloged. I cleaned up the mess Again and started the same bearings but with lower temp - 205C. But it doesn't help and I had to repeat cleaning and pulling out the filament after half hour. Next, I decided to raise the temp to 215C (over 5 that mentioned in spool) on my model and after approximately half (!) hour I again had to stop this because filament has been blocked.

Today, after about 3 hours of removing stucked piece of filament from PTFE tube I'm really afraid to check this material one more time but I'm afraid I have to. It's not only a matter of money for filament (which is not cheap!) but also of probability of buying new extruder or burning extruder motor - and this could be really problematic.

I've found on some forum that this situation is common for ColorFabb PLA/PHA and the reason is a temperature sensitive of this material: when there's too warm in extruder body, diameter of filament grows so significantly that friction blocks pushing it and pulleys starts to bend and grind it. In two cases which were successfull (whistle and 100% infill cube) I used full speed and models aren't big - maybe heat distribution up to extruder body hasn't reached "blocking" level as for other models? But it doesn't solve cases for bigger and complicated models which require, for example 50% speed and at least few hours.

Current observations:

- all models was small (less than 50 mm)

- whistle and 100% infill 20x20x20 cube printed successfully with 210C and 100% speed,

- bearings failed for: 200, 205, 215C and 70% speed

- printer (Prusa i3 MK3) inside enclosure (maybe temperature on extruder level will be so high?)

- filament stopped after about ~30 min.

- setting bed temp to 50C for lowering heat inside enclosure wasn't help

- filament right below pulleys was bent over but not broken so it had to be soft - still warm enough few centimeters above the nozzle

- filament is really stiff (as wire) and has local bendings because the way it was wound up on spool

- I haven't such complications for other manufacturers and materials PLA, PET, PET-G, ABS, PA12, PP, ASA, PMMA, PC and even TPU or BIOFLEX

To check:

- printing without enclosure

- extruder temperatures: 190 (maybe even lower?), 195, 200

- bed temperatures: 50C, 55C,

- set at least 40mm/s printing speed as mentioned on the box

I hope to try this without problems but If anyone have a solution or discovered some magic settings, please respond.

Re: Colorfabb PLA/PHA Failing repeatedly

+1 on extruder/ambient temp

I use the 2.2kg rolls exclusively for prototyping and occasionally I get adhesion problems when swapping between filaments. I unload and reload the PLA and run it through the hotend a couple times and hit the PEI with a Acetone wipe, this usually fixes it straight away. Looking at your photos, the PEI looks like it needs a good clean and possibly ease off the Z a touch, looks like its bulldozing the filament off.

Don't use too much tension on the idler with this stuff as it is very temp sensitive, generally over 30c ambient will have it wrapping around the extruder gears in no time. For me its a great filament, large rolls, dimensionally stable and vcheap!

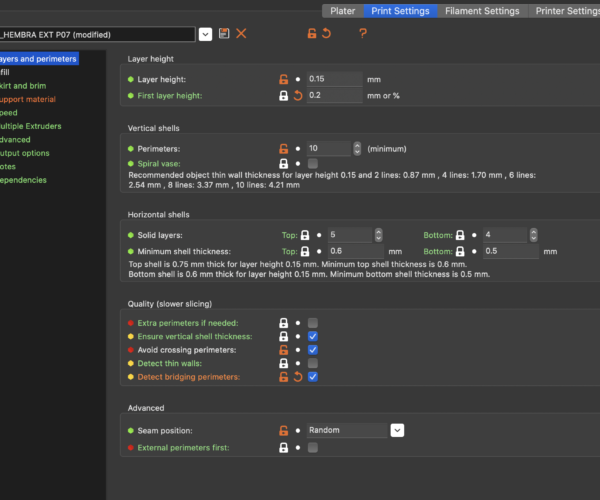

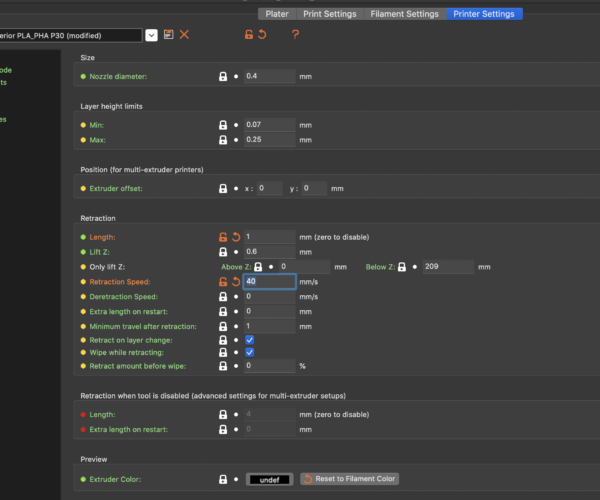

My settings below.

Re: Colorfabb PLA/PHA Failing repeatedly

@Jan - I see a lot of fingerprints on the bed. PLA and hand oils don't mix. I've also seen this problem with a new roll of filament where someone at the factory had apparently just applied hand lotion and the entire first layer of filament almost foamed as it extruded. After the first layer was used the filament started sticking as well as other filaments.

Rereading ... I can add that once in a while debris from the gears cutting into the filament will fall down into the PTFE and collect at a narrow spot, like where the PTFE is formed into a V at the end. If enough collects, it starts to compress and jams; you see the exact same symptoms as a nozzle jams. The difference is this heat break jam takes time to form after starting a print. Short duration prints work, longer duration prints fail.

You might try removing the filament, and blowing compressed air down the PTFE tube to see if any loose material comes out. In one of the times I had this, I had to remove the nozzle and blow upwards through the hot end: I was amazed at how much material came out.

Re: Colorfabb PLA/PHA Failing repeatedly

Hello,

two days ago I wrote my problems with ColorFabb PLA/PHA printing. In my case those settings are key for no problems:

So descriptions directly on the label attached to spool are right: 190/195 C nozzle temp. I thought that purchase of this material was a mistake and I lost my money, but with mentioned settings models are ok and have high quality of surface and really sharp dimentions.

Re: Colorfabb PLA/PHA Failing repeatedly

I'm here to report that I'm having the same issue with ColorFabb's PLA/PHA spool. I've been printing with eSun PLA+ for almost a year. Wanted to try other brands, switched to ColorFabb (around 3 times more expensive than eSun PLA+) and troubles started.

The exact same settings that I had no issues whatsoever with eSun PLA+ doesn't work with ColorFabb PLA/PHA. Than I said, okay, it's a different filament, let's try to tune it. I went as low as 25 mm/s2 acceleration on the first layer, but still, on zig-zags/sharp corners, this filament is extremely easy to lift off the bed. I'm printing relatively slow (20 mm/s).

I went ahead and played with live-adjusting Z, no luck. The only way I've found is to squish it to the point that the first layer looks like total crap/bulldozed, as the nozzle scratches the already printed filament on zig-zags and creates a very bad looking, rough surface. And at that point, the back-pressure created is so much that the filament starts to escape from the sides and stick to the nozzle itself on everywhere, creating a mess.

I've checked e-steps and it's perfectly tuned, when I tell my printer to extrude 100 mm, it extrudes exactly 100 mm. I've also checked the extrusion multiplier and it seems to be spot on, as described in Prusa's manual (with the precise method, came out exactly 0.45 mm on side walls as expected).

I've tried temperatures from 195C to 220C on the first layer and 60-70C on the bed, none worked. I've cleaned the PEI sheet with IPA (as suggested on the manual and everywhere else) and no luck either.

I'm starting to regret this purchase. 😐

Re: Colorfabb PLA/PHA Failing repeatedly

I'm having pretty much the same issue. I got it to lay down a skirt correctly only once then it curled around the nozzle at the start of the print. I have one of the printers set up with a textured plate i bought off of amazon and it failed just as bad. Like you this is the only purchase of filament i have regretted. One strange observation. after putting in an older spool and purging the pla\pha the first few prints will fail but after a few retries everything goes back to normal.

Re: Colorfabb PLA/PHA Failing repeatedly

given the fingerprints on your plate, the best prep for your bed is to wash it with warm water and dawn dish soap (in the UK use Fairy liquid) by using a wad of clean kitchen paper towel dampen with warm water and put a dollop of Dawn on the pad and scrub (i do it twice at 90 deg to each other holding the plate by the edge as it is a phonograph record rinse under running water and dry with clean paper towel keep touching only by the edge... I do this every other day of printing with both kinds of plate.

then set your live z with this method https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html it is far better than the zig zag method in the firmware

RE: Colorfabb PLA/PHA Failing repeatedly

Hello,

two days ago I wrote my problems with ColorFabb PLA/PHA printing. In my case those settings are key for no problems:

- nozzle temp: 195C (first layer), 190C others

- printing speed at least 40-100 mm/s as mentioned on box (or 100% printing speed on all layers if possible, even for complicated models)

- bed temp: 60C for all layers

- no printer enclosure

So descriptions directly on the label attached to spool are right: 190/195 C nozzle temp. I thought that purchase of this material was a mistake and I lost my money, but with mentioned settings models are ok and have high quality of surface and really sharp dimentions.

Hi Everyone,

I'm having the same issues with Colorfabb PLA/PHA. I bought this with te though of improvement but after 3 days testing every little setting I can't get a decent first layer all te time. 🙁

I'll Try 195º in the nozzle and 190º others.

RE: Colorfabb PLA/PHA Failing repeatedly

@rubenvilagrand

A picture of first layer would help and as much info as possible.

RE: Colorfabb PLA/PHA Failing repeatedly

Hello,

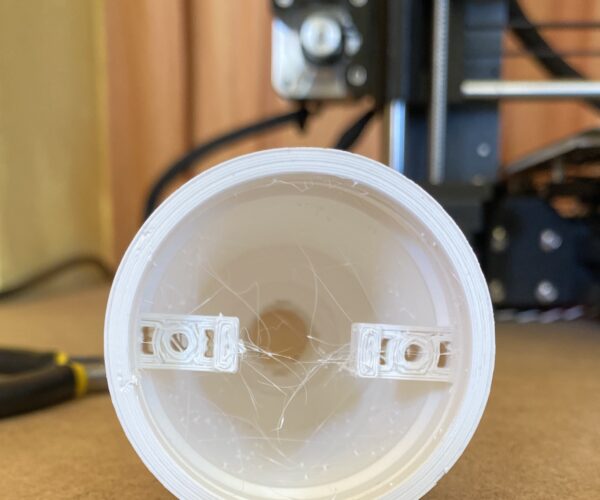

After try many different settings a managed to have kinda stable printings. but I still have sometimes some stringing.

Hereby I add a Screenshot of my settings and some pics.

The pics with strings and wraps is when I ave the default settings for Colorfabb PLA/PHA in Prusa Slicer.

Best Results (Pic without strings) is when tune up the retraction length from 0.8 to 1 mm and retraction speed from 0.35 mm/s to 40mm/s. Although when I print in 0.15 instead of 0.20 (Layer thickness) i find more strings too.

Please if somebody have mor info or tips I wold really appreciate it.

Thank you in advance,

Rubén

RE: Colorfabb PLA/PHA Failing repeatedly

I got a roll of PLA yesterday,

It's Chinese No Name filament in white and strings like crazy!

I tried a temperature tower 220C to 190C and all temperatures were stringing, so I did another temp tower, and the best temperature turned out to be 170C.... Much lower than expected.

Maybe your filament will work better at a lower temperature!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Colorfabb PLA/PHA Failing repeatedly

I was just having the same issue with ColorFABB PLA/PHA (white). Couldn't get the first layer to stick. I went over to use Cura due to their supports being more accurate and I ended up applying one raft layer to see how that stuck. The raft layer ended up printing perfectly. Since I try to avoid using raft with parts that I feel like should be able to be printed with out it, I took the settings that the raft was being printed at and applied those to the initial layer settings, and omitted the raft. The setting modifications with a 0.4mm nozzle are:

Layer height: 0.3mm

Initial layer height: 0.24mm

Initial layer line width: 200%. Cura did warn me that this was excessive, but I went ahead with it anyways

Initial layer print speed: 22.5 mm/s

The first layer printed much better and I was able to get the whole part out. There are still some minor defects, but should be able to tweak a couple setting to get those solved.

I normally use PrusaSlicer as there are some features in it that I really like using, but I find it is missing "Initial layer speed", and supports sometimes go outside the areas I want them to. I switch over to Cura when these are critical.