RE: Buldge when print reaches "solid" layers

Hey @tim-m30, no don't do that, I went ahead and recreated and zipped up 3mf. But honestly I can't recall if for the interior part I made 100% infill with rectilinear (still with no top layers) or if I just allowed it to have top and bottom layers. That was the only adjustment I made from a standard prusa setting. Other than I have a slight filament extrusion adjustment.

RE: Buldge when print reaches "solid" layers

Hi, I thought it was my settings, I'm having the exact same issue as many others. Check the image below, the first two on the left sliced by CURA seems to be fine, and all of the rest of the right with different settings, all seems to have issues...I have attached a STL for you all test, it should be a quick 20 mins print, you don't need to print all the way up to see the problem. Let me know your results please.

STL file: https://drive.google.com/file/d/1qjrq-yZa6fhl9OKLnExPNV0I8JRopGRH/view?usp=sharing

RE: Buldge when print reaches "solid" layers

I just wanted to mention I printed a shell using "Exterior perimeters first" which had the strange consequence of making every layer above the "bulging layer" as thick as the bulge so it actually looks like the bottom solid layers are indented instead. Its not a fix by any means, but reduced the "bulging" effect in only 1 spot.

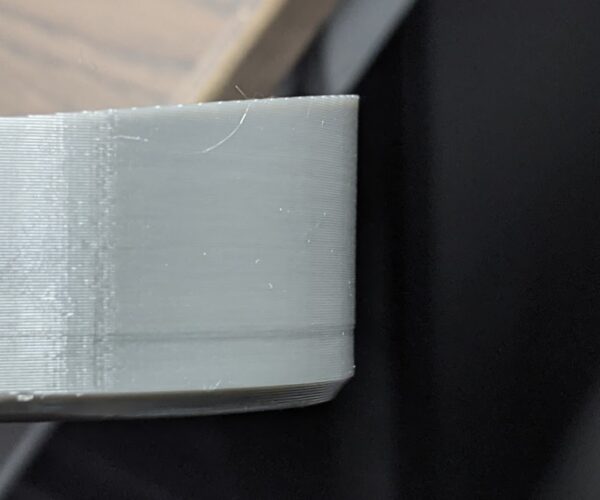

This is as far as I've gotten to improve my print as well with @bobstro's suggestions... crazy how identical this is...

- slowed down print speeds for any and all perimeters

- 4 perimeters for this 7mm wall

- detect thin walls is on

- external perimeters first

Other settings

- SunLu PETG - 240 nozzle, 90 bed

- 30% infill

Do we know if infill is affecting the bulge? That is, is Gyroid suspect?

Funny that I did not have this on my older print of a similar shape about a year ago. Nice flat walls back then. Actually pondered rolling back my firmware and Prusa Slicer and trying that older setup. I usually install the official releases(not beta or alpha) as for slicer and firmware for my MK3s as soon as they come out.

MK3s / My IKEA Lack enclosure

RE: Buldge when print reaches "solid" layers

@jurassic73

I have noticed a difference with different infills. Rectilinear seeming to be the worst. But in the experimenting I've done it seems to show up with all the infills. I have decent luck on cosmetic items that I print face down by removing top levels (using modifier meshes) and using Triangles at 95% infill for as few as layers as possible. Most people won't have that option of course because they need a solid layer. My top shelf is object's bottom and is covered with foam rubber, so not an issue for me.

I do recommend people consider removing top layers by using a modifier mesh and replacing it with solid infill of different types to see if anything works better.

RE: Buldge when print reaches "solid" layers

[...] Let me know your results please.

Here are my results printing with Prusa default profiles for the Mk3, generic PLA, and 0.2mm SPEED print settings on the left, and my tweaked settings with tuned filament, modified print settings including adding a 4th perimeter on the right, and aligning the z-seam in the same corner.

At 600% zoom, both look horrid. At normal size, the defaults show a pronounced appearing (but small in dimension) inward step towards the bottom. The finish is also a bit more distorted at the transition from sparse to solid layers from the bottom. The tweaked settings produce smoother and more even walls... though I seem to have picked up a bit of elephant's foot along the way.

This is a very annoying problem to track down simply because there are so many variables.

RE: Buldge when print reaches "solid" layers

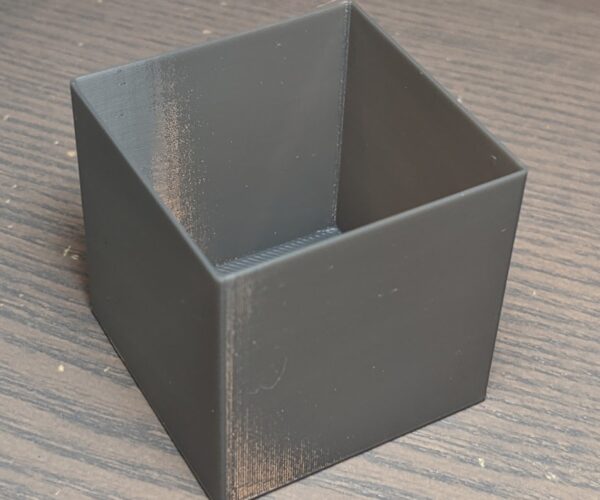

Crazy I can just go easily print this vase mode cube with great results... but add in some layers and thickness and it goes south without heavy tweaking to get okay results.

MK3s / My IKEA Lack enclosure

RE: Buldge when print reaches "solid" layers

Do check the undersides of prints to make sure you're not getting any warping. Parts printed with more layers and thicker walls will have more thermal mass. The larger they are, the more likely they are to warp due to uneven cooling. In some of the pics in this thread, there does appear to be a slightly uneven underside, indicating slight warping in the areas under the defect. If nothing else, this will contribute to the problem.

RE: Buldge when print reaches "solid" layers

Do check the undersides of prints to make sure you're not getting any warping. Parts printed with more layers and thicker walls will have more thermal mass. The larger they are, the more likely they are to warp due to uneven cooling. In some of the pics in this thread, there does appear to be a slightly uneven underside, indicating slight warping in the areas under the defect. If nothing else, this will contribute to the problem.

What are the results of printing with two perimeters and then two top and bottom layers?

Also, does a fillet inside help at all?

MK3s / My IKEA Lack enclosure

RE: Buldge when print reaches "solid" layers

@jurassic73

Wall is too thin to verify it, do you mind to print the exact same STL file and let us know please?

STL file: https://drive.google.com/file/d/1qjrq-yZa6fhl9OKLnExPNV0I8JRopGRH/view?usp=sharing

RE: Buldge when print reaches "solid" layers

@jurassic73

I get this same result when I print small tube containers. I am not sure why.

--------------------

Chuck H

3D Printer Review Blog

RE: Buldge when print reaches "solid" layers

Something I have done which helps is make sure your wall thickness is exact multiples of extrusion widths.

Eg if your line width is 0.45mm, then try your wall thickness at 0.9mm or 1.35mm.

The idea is as follows, trying to print a 1mm thick wall with a 0.45mm nozzle means you are trying to print an infill of 0.1mm between the two 0.45mm perimeters, which can't be done, what tends to happen is you end up with under or over extrusion which manifests itself as a step.

These days, I go through all widths when designing something to check for this issue and get much cleaner prints than I used to, not perfect, but I guess this is what happens when you use a molten sausage maker to print things.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Buldge when print reaches "solid" layers

Something I have done which helps is make sure your wall thickness is exact multiples of extrusion widths.

Eg if your line width is 0.45mm, then try your wall thickness at 0.9mm or 1.35mm.

The idea is as follows, trying to print a 1mm thick wall with a 0.45mm nozzle means you are trying to print an infill of 0.1mm between the two 0.45mm perimeters, which can't be done, what tends to happen is you end up with under or over extrusion which manifests itself as a step.

These days, I go through all widths when designing something to check for this issue and get much cleaner prints than I used to, not perfect, but I guess this is what happens when you use a molten sausage maker to print things.

This has actually been in the back of my brain but something I didn't think was critical. It seems like in this case it's one less variable so I'll go look at my design and see if I need to push pull things to get it to some multiple of 0.45.

MK3s / My IKEA Lack enclosure

RE: Buldge when print reaches "solid" layers

@jurassic73

I think this is a wise design decision but in my hands is not a solution for the "bulge when there's an interior flat surface" issue.

What I've seen in a previous post and I want to try soon is to Print External Perimeters First. Intuitively that feels like something that makes sense.

RE: Buldge when print reaches "solid" layers

@chocki

That's not practical at all, we simply cannot alter the design because of the slicer's limitation? Right?

The first two prints on the left, was done by Cura with 0.4mm extrusion width and it printed perfect, so I don't think that's the problem there.

I want to solve it because I like the surface smoothness using PrusaSlicer...until now, this issue came up.

RE: Buldge when print reaches "solid" layers

@fuchsr

I've tried to print the external perimeters first too...didn't help.

RE: Buldge when print reaches "solid" layers

Another test print...this time sliced by SuperSlicer...same results. I've set the print speed for the perimeters the same...and that didn't help either.

RE: Buldge when print reaches "solid" layers

@jurassic73

I think this is a wise design decision but in my hands is not a solution for the "bulge when there's an interior flat surface" issue.

What I've seen in a previous post and I want to try soon is to Print External Perimeters First. Intuitively that feels like something that makes sense.

printing external perimeters first was part of the list of items I tried all at once and got my best print but it still had a ledge versus a bulge. That is it was kind of like a step if you were to exaggerate the surface profile.

I did notice when testing a smaller square of similar dimensions regarding wall thickness and height in that the bulge or step was much less but still present. I wonder if it is proportional to the size of the print. That is if you actually made a square the size of your print bed, would that step be greater on the side, more exaggerated?

MK3s / My IKEA Lack enclosure

RE: Buldge when print reaches "solid" layers

I have tried all these things. I am eager for a solutions also,

--------------------

Chuck H

3D Printer Review Blog

RE: Buldge when print reaches "solid" layers

A few notes based on experience futzing with this issue for some time:

Making walls an exact multiple of extrusion width may help, but probably not for the reason you're thinking. PrusaSlicer inherited Slice3r's internal calculations for spacing of extrusions. The actual distance between 2 adjacent extrusions is calculated as:

spacing = extrusion_width - layer_height * (1 - PI/4)

There is a slight calculated overlap between adjacent extrusions, and this is hidden from the user.

Printing external perimeters first may help with vertical walls. However, it may cause problems with sloping walls due to lack of adjacent or underlying material for those outward-sloping wall extrusions to adhere to.

There is another ongoing discussion on this topic and I'm going to post follow-up testing results there for anybody interested.

RE: Buldge when print reaches "solid" layers

I just hope that a) there *is* in fact an engineering solution to this problem, and if so b) with 17 pages and counting on this issue (not including the other related discussion in this forum) Prusa engineers and folks working on PrusaSlicer take a look at this issue and can find something that makes it either go away or less of an issue for most cases, without having to resort to experimentally optimizing each and every model by itself.