2nd layer adhesion issues?

I've got the first layer calibration stuff down pretty well as per https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/1st-layer-troubles-on-large-prints/ & other places.

I've got some new Overture PLApro filiment & am trying to print a drawer that's close the the size of the build plate. The first layer went down well, but my wife stopped the print because it was making a racket & well, it looked pretty obviously wrong when she found it. There might be some slight bed adhesion issues in the corners on the bottom & a few minor blemishes, but otherwise pretty good. But it looks like the center of the 2nd layer just isn't adhering to the first layer. I'm using the PrusaSlicer Generic PLA defaults of 215/60 for the first layer & 210/60 for the other layers, which matches up with what the PLApro says to use.

Any guidance on where to start debugging?

Best Answer by Neophyl:

that pla range really does depend on the filament though, there are so many variations on the pla 'recipe' that different manufacturers use. I normally print any pla at 215 as I have a nozzle X so needs a bit of a bump but I have some pla that the temp range listed for it is 200-225 and it prints very nicely at 230 with my setup.

You pretty much have proved that though by printing with the other filament where it works. Peter is also correct about the max volumetric rate, 15 is ok with some filament/hotend/nozzle combos but with other its too much. Then again with a bigger nozzle, different temps etc you can actually go more than 15 🙂 If I'm being cautious and I don't want to do all the tests to find the actual best max volumetric I set it to 12mm.

RE: 2nd layer adhesion issues?

I think it is because prusa has problems with big flat objects and the high speed it want to do.

You can do 2 things, higher temperature, 15 c higher or 20 C higher.

Or slow down the printer in the speed settings.(test what you want to do).

Personally, I find higher then 130 mm to high.(see speed settings).(to much wear on parts-noise).

In forum in some threads you can see, that prusa sets speed on 15 mm in filament settings, maximum volumetric speed 15 mm, this is to high, set this to 11 mm. Normally I slow down, for less wear on the printer.

RE: 2nd layer adhesion issues?

How to do a first layer calibration.

Important small and big flat objects.

Clean bed with dish soap,(better sticking)

first layer 100%,(better sticking),

If possible use a big brim attach to model with 6 lines,(better sticking)

RE: 2nd layer adhesion issues?

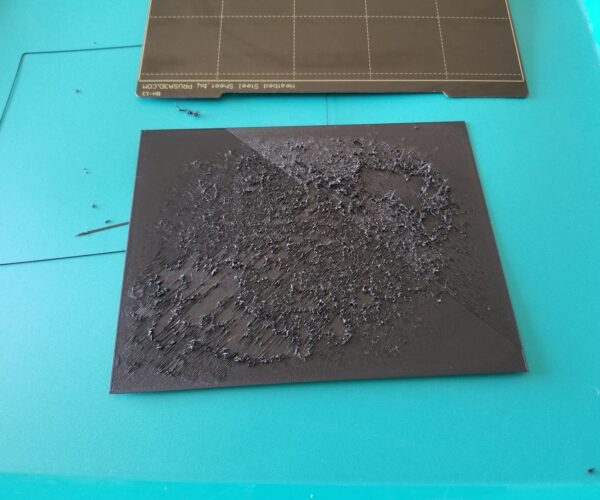

I took another look at the failed print & the first layer looks good. I think the 2nd layer might be good as well. It's the 3rd or 4th layer that doesn't appear to have stuck & looks like grass or what not. The first photo is the bottom side after I removed it from the bed. You can see a little color change in the corner that might be a bit of a bed adhesion issue. Everything was pretty well stuck to the bed when I got to it later after my wife stopped the print. Only the center of the upper layers seems to have had any issues, not the edges where I'd have expected. The 2nd photo is the top of the same failed print as the first photo.

RE: 2nd layer adhesion issues?

I think it is because prusa has problems with big flat objects and the high speed it want to do.

You can do 2 things, higher temperature, 15 c higher or 20 C higher.

Or slow down the printer in the speed settings.(test what you want to do).

Personally, I find higher then 130 mm to high.(see speed settings).(to much wear on parts-noise).

In forum in some threads you can see, that prusa sets speed on 15 mm in filament settings, maximum volumetric speed 15 mm, this is to high, set this to 11 mm. Normally I slow down, for less wear on the printer.

RE: 2nd layer adhesion issues?

The issue is only showing up using Overture PLA Pro black. Went back to the tail end of a spool of black Hatchbox PLA & it printed the bottom of a drybox just fine (bottom). Same bottom failed horribly in the same way when I tried Overture (top). Ran out of the Hatchbox & had to go back to Overture to finish off the top of the print, which worked fine other than a irrelevant surface finish change.

The wife repoed the printer for a bit so I'll have to wait to see if higher temps sort it out. 215 nozzle temp is already up there at the top of PLA range & what Overture recommends.

RE: 2nd layer adhesion issues?

that pla range really does depend on the filament though, there are so many variations on the pla 'recipe' that different manufacturers use. I normally print any pla at 215 as I have a nozzle X so needs a bit of a bump but I have some pla that the temp range listed for it is 200-225 and it prints very nicely at 230 with my setup.

You pretty much have proved that though by printing with the other filament where it works. Peter is also correct about the max volumetric rate, 15 is ok with some filament/hotend/nozzle combos but with other its too much. Then again with a bigger nozzle, different temps etc you can actually go more than 15 🙂 If I'm being cautious and I don't want to do all the tests to find the actual best max volumetric I set it to 12mm.

RE: 2nd layer adhesion issues?

Got it sorted it looks like.

Printed a temp tower (one on the right, other is PETG) & there was no difference between 190 & 220. Hint of gloss on 225 & 230.

Re-sliced it at 220 & volumetric efficiency set to 11. Added a brim for good measure, but that wasn't related to the issues in the middle. Surface finish looks worse in the photo than in real life.

Might try to dial it in with a higher volumetric. Or not & just be lazy with it going a bit slow on that Overture PLA Pro.

RE: 2nd layer adhesion issues?

Did a search and found this thread. Earlier tonight I used Overture white PLA for the first time on my Mk3S+. I ran into the same problem with the 2nd layer as you; very rough, with a "grass growing" look to it. I started with the generic PLA in Prusaslicer. I'm printing storage trays that fill the print area on the plate. Funny thing is, the first layer was the best looking 1st layer of all the filaments I've used for these trays. I've compared HatchBox, Sunlu, Paramount3D and now Overture with all these trays I'm making for my wife. Perfect first layer, 2nd layer so bad I had to stop the print. Re-sliced using Prusament template and same problem although very slightly improved. I saw that this template uses a little higher nozzle temp.

I ended up slowing travel down to 75% and jacking nozzle temp up to 220C. Travel speed has a major effect on this. With these settings I'm getting satisfactory results. I found your post after doing some research to see how I can improve with this filament, because I've read where some have very good luck with it.

Ted

RE: 2nd layer adhesion issues?

On looking at your first picture, there is a shadow on the print bed that looks to be in the same shape and position as the later rough print area.

This is a guess: I wonder if you have bad adhesion in the centre of your print but the object is held down by good adhesion outsie the area. This could allow the centre to rise into trouble without displacing the print.

In this case cleaning the bed would help, as would slowing the print to allow the nozzle to melt through the roughness instead of grinding into it.

Cheerio,

RE: 2nd layer adhesion issues?

Posted : 02/05/2020 6:36 pm

-- next post --

Posted : 20/05/2021 5:49 pm