Y-axis play after following the new instructions post v3.14 manual

My Y-axis started making some kind of metallic grinding noise recently. I decided to proceed to the maintenance of the Y-Axis assembly on my MK3s where I discovered these new instructions for the assembly.

I re-greased the bearings and change their orientation as shown in the picture but since then I feel there's even more play on the X-axis (left and right) for the Y-axis assembly. This play also increases the resonance of the metal grinding noise when the heatbed is moving. Is it a sign of damaged bearings or wear on the rods? I did a visual inspection and I don't see any wear or grooves in the rods.

Is replacing the rods and the bearings could help? Also, what's the difference between the LM8UU offered on the Prusa Store at $1.89 USD while on the MiSumi store the same bearing model is $12.60 USD?

P.S Before you ask, I did not overtighten, the U-bolts

RE: Y-axis play after following the new instructions post v3.14 manual

My Y-axis started making some kind of metallic grinding noise recently. I decided to proceed to the maintenance of the Y-Axis assembly on my MK3s where I discovered these new instructions for the assembly.

I re-greased the bearings and change their orientation as shown in the picture but since then I feel there's even more play on the X-axis (left and right) for the Y-axis assembly. This play also increases the resonance of the metal grinding noise when the heatbed is moving. Is it a sign of damaged bearings or wear on the rods? I did a visual inspection and I don't see any wear or grooves in the rods.

Is replacing the rods and the bearings could help? Also, what's the difference between the LM8UU offered on the Prusa Store at $1.89 USD while on the MiSumi store the same bearing model is $12.60 USD?

P.S Before you ask, I did not overtighten, the U-bolts

The LM8UU are cheap noname products of lower quality and the LMU8 Misumi are higher quality linear bearings and cost accordingly more.

Let everyone decide for himself what he wants to use.

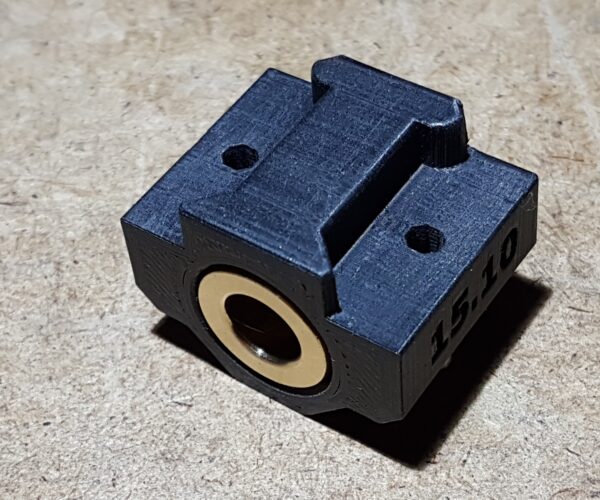

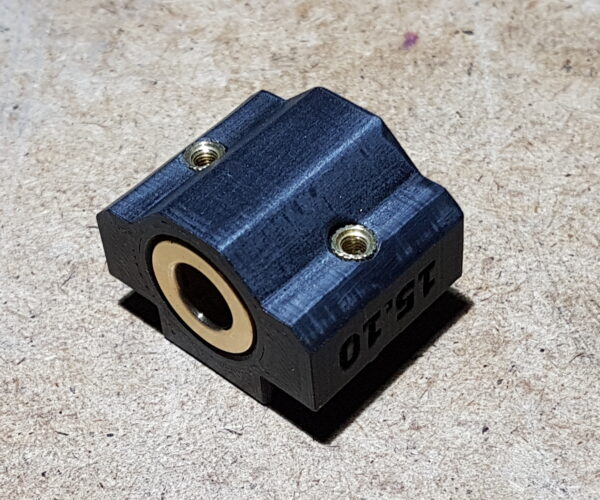

I myself prefer the original Misumi, housed in a custom made bearing housing (as usual) instead of the U-bolts.

(picture: example with brass bearings)

Advantage: More precision, smooth running. The bearings are glued in (Floating and fixed bearing principle) and therefore cannot be stressed with overtightened screws.

The mechanics of the printer also affects the quality of the print results.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Y-axis play after following the new instructions post v3.14 manual

@karl-herbert

Thank you Karl, very interesting that housing for the bearing. Do you know where I can find the STL for the i3? Also what is the model number of those brass bearings?

RE: Y-axis play after following the new instructions post v3.14 manual

@fred-bouchard

i have published this in prusaprints: https://www.prusaprinters.org/prints/45941-gehause-fur-linear-oder-gleitlager-15x8x24-lmu8-od

the brass bearings I bought here: brass/graphite bearings

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Y-axis play after following the new instructions post v3.14 manual

In general, the printer tends to print the holes smaller. For this reason I have added step data so that the hole diameters can be modified with any CAD software.

If somebody wants to use brass bearings, I would recommend to use a few drops of oil or grease in addition to the graphite fixed lubrication. I myself use an oil/PTFE based lubricant.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Y-axis play after following the new instructions post v3.14 manual

Hi,

the link seems to be broken. Are the files still available somewhere? With the housing, does the bed come up to some extend or do the pads on top go into the groves in the carrier?

Thanks

Juryk

RE: Y-axis play after following the new instructions post v3.14 manual

That's because it looks like Karl has done some reorganising. Try https://www.prusaprinters.org/prints/51755-prusa-mk3s-mini-y-achse-gehause-fur-sinterbronzela

RE: Y-axis play after following the new instructions post v3.14 manual

Thanks, this works!

Does anybody have experience with the DRYLIN Bearings from IGUS to reduce slackness? Or are they wearing too fast?

Karl also writes he uses the 3dktop by 3dk.berlin. Is PETG a no-go here?