What's the correct way to resolve this jam/clog?

Hello!

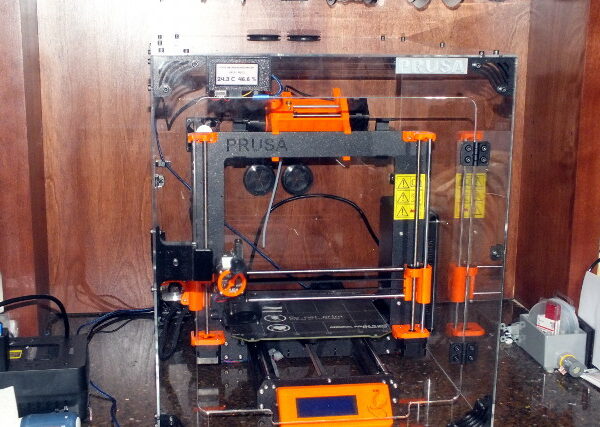

Printed a 3D benchy earlier in the new enclosure, and was supervising the print via a webcam. I went away for ~15 minutes and of course, tragedy struck. The filament spool holder had evidently loosened, and the spool slipped into a notch and stopped rotating. The printer of course kept trying to draw filament, but nothing was moving. I came back to find a printer making a pretty unhealthy noise and a half-chewed benchy. I shut the printer down and then restarted it and attempted to unload the filament (Prusa PLA). The door on the extruder rattled nastily and the filament wouldn't unload. I went through the instruction book, and it became apparent that I'd need to open the door. Was presented with this:

Now I'm fairly sure that the nozzle itself is clear; PLA oozed out of the nozzle at 260°C. It's just that big lump above the hotend. I'm just unable to get the filament out using either the loading or unloading method. Heating the printer to any temperature doesn't appear to affect that lump (and I guess it shouldn't, given the location). The documentation doesn't seem to cover this one.

RE: What's the correct way to resolve this jam/clog?

You may end up disassembling the extruder, but if this happened to me, before I would tear things down I would heat the thing up, far above PLA temperature, like 250c or so, and let it sit, like half an hour to an hour and let the heat conduct and radiate upward. Then use needle-nose pliers or other suitable tool to try to remove the blob.

PLA does soften at a relatively low temperature, so with heat and time you may save yourself some work.

RE: What's the correct way to resolve this jam/clog?

As you have just learned - printing PLA in an enclosure is not a good idea. Leave the enclosure door wide open when printing PLA. Otherwise, expect more experience reassembling new hot ends.

RE: What's the correct way to resolve this jam/clog?

You may end up disassembling the extruder, but if this happened to me, before I would tear things down I would heat the thing up, far above PLA temperature, like 250c or so, and let it sit, like half an hour to an hour and let the heat conduct and radiate upward. Then use needle-nose pliers or other suitable tool to try to remove the blob.

PLA does soften at a relatively low temperature, so with heat and time you may save yourself some work.

Right! Thanks. Yes, I'd like to avoid disassembling the extruder if at all possible. It took most of a day to assemble it the first time around. I'm going to try heating and attacking with needle-nose pliers shortly.

RE: What's the correct way to resolve this jam/clog?

As you have just learned - printing PLA in an enclosure is not a good idea. Leave the enclosure door wide open when printing PLA. Otherwise, expect more experience reassembling new hot ends.

Yep! To be clear, in this case the problem was the filament spool holder. The spool stopped turning so the existing filament just sat in the extruder, melting and going nowhere. I take your point though, I'll be printing PLA with the door open from now on. The enclosure is primarily so that I can print ABS anyway.

RE: What's the correct way to resolve this jam/clog?

And what exactly is wrong with printing PLA in a temperature-regulated enclosure?

Ever since I installed the enclosure I've used it, door closed, thermally regulated, for all filaments including PLA.

If anything, it helps with the temperature stability.

RE: What's the correct way to resolve this jam/clog?

And what exactly is wrong with printing PLA in a temperature-regulated enclosure?

The E3D V6 hotend is rated to 40C ambient operating temperature. As you approach that temp, the cooling efficiency of the air cooled design is reduced, allowing more heat up past the heatbreak. With a low temp filament such as PLA, this heat creep can cause the filament to soften far up enough in the mechanism to cause feed problems.

It's not that an enclosure is inherently bad, but a combination of a hot enclosure and some filaments can be problematic.

Every summer we see a spike in heat creep problems. Enclosures or even just hot rooms can contribute to the causes.

RE: What's the correct way to resolve this jam/clog?

And what exactly is wrong with printing PLA in a temperature-regulated enclosure?

The E3D V6 hotend is rated to 40C ambient operating temperature. As you approach that temp, the cooling efficiency of the air cooled design is reduced, allowing more heat up past the heatbreak. With a low temp filament such as PLA, this heat creep can cause the filament to soften far up enough in the mechanism to cause feed problems.

It's not that an enclosure is inherently bad, but a combination of a hot enclosure and some filaments can be problematic.

Every summer we see a spike in heat creep problems. Enclosures or even just hot rooms can contribute to the causes.

I set the control points of the enclosure for PLA at 29.0 and 30.9, which is not much warmer than a non-air-conditioned room. PETg and ABS are set warmer, as you might figure. For PLA I'm going for a consistent range, not a warmer environment.

RE: What's the correct way to resolve this jam/clog?

I set the control points of the enclosure for PLA at 29.0 and 30.9, which is not much warmer than a non-air-conditioned room. PETg and ABS are set warmer, as you might figure. For PLA I'm going for a consistent range, not a warmer environment.

Sounds like you've got a "real" enclosure with those controls. Next summer, watch for a spike in heat creep posts from folks happily assembling the inexpensive Lack enclosures. Again, it's not that "enclosures are bad" but "excessive heat is bad". Whether due to high ambient temps (one guy in the Pacific has everyday room temperatures of 40C/104F routinely) or over-heated enclosures with no ventilation or air circulation, too much heat can cause premature softening.

I think this is one of those things like the stepped heatbreak, extruder tension and extruder motor heat. There's a wide range of temperatures and conditions, some of which affect some users and not others. I notice you're also posting in another thread on using heatsinks on your extruder motor. I've never had to do that myself, but it is a common problem. Unfortunately, there's no one-size-fits-all solution. Asking about enclosure use is just a normal part of the troubleshooting process.

You should post details on your enclosure setup. Some good advice on "doing it right" would help a lot of folks realize they need to do more than slap plexiglass on a lack table and call it done.

RE: What's the correct way to resolve this jam/clog?

I wrote up the enclosure assembly a while back.

It's a 3d Upfitters stock enclosure except I used a fan with a little more 'oompf' that I had around and used a Pi Zero W and a generic temp (and humidity - this was one I had on hand) sensor to control it.

RE: What's the correct way to resolve this jam/clog?

Yes, I added that heat sink a while back, mostly because it felt hot to the touch and also because others here remarked that theirs were running warm too. I have all kinds of stuff like heat sinks around and some (supposedly) thermally-conductive adhesive so I just added it to be safe rather than sorry.

RE: What's the correct way to resolve this jam/clog?

I wrote up the enclosure assembly a while back.

Nice! That would be a good starting point for anybody looking into an enclosure.

RE: What's the correct way to resolve this jam/clog?

Ok, so the patient outcome was good!

No amount of heating would help, so I decided to disassemble the extruder. It didn't take anywhere near as long to disassemble as it took to assemble it originally. I only needed to remove six screws to remove the fan shroud and extruder motor, and to expose the hotend. I managed to clip the filament above the lump and unload, and was then able to remove the PTFE tube from the hotend. I was presented with this:

No damage to the tube, luckily, and none to the hotend or nozzle. I reinserted the PTFE tube, cleaned the Bondtech gear on the extruder motor, reassembled the extruder, and loaded fresh filament. The machine has printed a PRUSA logo and a benchy with no quality issues or other defects.

I think the sequence of events was this:

1. The filament spool holder snagged, because I evidently hadn't tightened up one of the bolts as tightly as I should have. This meant the machine stopped being able to draw filament near the end of the print.

2. I then made the fatal mistake of switching off the machine mid print (because at that time, I had no sensible way to halt the print). This almost certainly resulted in heat creep up to the end of the PTFE tube, and this caused the filament to melt and form the blob that lodged in the top of the PTFE tube and made it impossible to unload the filament.

Lesson learned: Don't allow heat creep to occur. 🙂

As for the enclosure I'm using: It's an acrylic kit enclosure. It's fitted with a 120mm extractor fan that's always on, but it's not temperature regulated in the sense that I can manually set a temperature. I'll be fitting a temperature probe shortly so that I can monitor the ambient temperature during print jobs. Somewhat ironically: This disastrous print was the first print I've attempted in the enclosure, and I was only doing a quick 3D Benchy so that I could be sure I'd not misaligned the frame or caused some other issue when I moved the printer into the enclosure. This was supposed to be a quick test print just to verify the printer was OK! 😆

RE: What's the correct way to resolve this jam/clog?

The E3D V6 hotend is rated to 40C ambient operating temperature...

I'm mildly concerned by this. I'm in a relatively cold climate, and I'm routinely reaching 40°C ambient temperature during prints even without the enclosure (if the A value returned by the firmware is to be believed).

RE: What's the correct way to resolve this jam/clog?

I'm currently working my way through http://projects.ttlexceeded.com/3dprinting_mk3_extruder.html to see if I've made any obvious mistakes.

RE: What's the correct way to resolve this jam/clog?

@io7m

And what needs to be considered is the E3D-V6 hotend is rated to run at 40C, it isn't rated to run with PLA at 40C ambient. The spec is that is won't fail electrically at 40C. Also, the extruder, the motor and Bondtech, are not part of the E3D-V6 spec. lol. These are a Prusa design and as far as I know are not specified at any temperature.

So - running the i3-Mk3/S extruder above ambient is not a warranted operation. Sure, you might get lucky and have it work for your very specific case, but not everyone has those exact environmental conditions.

Generally - inside an enclosure, the Prusa i3-Mk3 will fail to print PLA due to overheating of the extruder assembly. Both filament melting above the Bondtech (as this case shows), and filament melting in the heat break (2.2mm stub jams at heat break step).

The extruder motor has a temperature rise of around 30 to 35c. At an ambient of 23, that means the motor will reach 55c or higher NORMALLY. If the printer is in an enclosure at 30c ambient, the motor will reach 65c or higher, NORMALLY. The glass point of PLA is around 65c.

A similar temperature rise inside the heat break takes place. The thermal gradient from the melt zone to the lowest fin on the heat sink is around 150 to 170c. Add 10c ambient and the melt zone creeps higher into the heat break and eventually reaches the Prusa step.

A fan on the extruder generally resolves the melting at the Bondtech gears. Why? A fan with shroud reduces the motor operating temperature about 20 to 25c - essentially cooling the motor case to ambient. A 40mm square x 11mm tall heat sink - based on my experience, oriented properly so convection air flow is aligned with the fins - reduces the motor operating temperature about 10 to 15c. Adequate for warm rooms, but not adequate for enclosures.

RE: What's the correct way to resolve this jam/clog?

Thanks! This is good data to have; very useful to have specific numbers.

My concern that I'm reaching 40°C is more that I'm uncertain why I'm currently reaching 40°C. There doesn't appear to be an obvious mechanical reason for it, and I'm not certain if I should believe the temperature lines I'm getting from the firmware. In any case, I'm actually printing without issue although it's entirely possible that I'm just repeatedly pushing my luck 😉.

Don't forget that the cause of the issue that caused me to ask for help in this thread was actually that my filament spool got caught. I then caused heat creep by abruptly removing all cooling (by turning the printer off at the wall). I suspect I would have had PLA-melting heat creep no matter what I was doing in that situation.

A fan on the extruder generally resolves the melting at the Bondtech gears.

Just so that I know I'm interpreting what you wrote correctly: You mean that without a fan, the motor would run at ~30°C + A°C, and with the standard fan setup, that becomes (~30°C + A°C) - ~20°C, giving you roughly A°C + ~10°C, yes? If A°C = 40°C, that gets you over the glass transition temperature for PLA without a fan, and just barely under it with one.

In the fine tradition of Russian Roulette players everywhere, I'm going to continue running PLA prints in the enclosure with the door open unless I see consistent failures. If I see consistent failures, jams, etc, I'll look at measures to reduce heat creep. I'm typically only doing quick draft prints in PLA to check dimensions and general part design soundness. Otherwise, it's PETG or ABS, and heat creep obviously isn't an issue there. Right now, I'm not even hearing extruder clicks or any of the usual "you're about to have a jam" warning signs.

RE: What's the correct way to resolve this jam/clog?

Let me rephrase that for the sake of pedantry. 😀

Heat creep isn't going to result in an extruder full of melted PETG or ABS (unless the printer is on fire). It might cause other problems, certainly.