Underextruding on PETG prints after using PLA

Hi,

I've mostly printed with PETG on my Prusa MK3S, but over the past week I ran through a spool of PLA. Now that I've switched back to a new spool of Prusament PETG my first layers are underextruded and there's a clicking sound that appears to be coming from the hotend. It's a little faster than 1 hertz and a little quieter than a skipping stepper. If I put my finger on the extruder motor I don't feel the "click" that I'd expect, so I don't think the motor is actually skipping.

There are a lot of variables:

- The PLA was no-brand junk, and I was surprised the mk3 printed so well with it (not a single failed print, stock prusa slicer PLA settings).

- The PETG is a new spool, so I don't have known-good prints with it. But I have printed with other colors of Prusament PETG previously.

- The printer crashed hard overnight after I'd loaded the PETG but before printing anything. Gave me this "blue screen". I power cycled it and it came back like nothing had happened.

- Prusa Slicer upgraded and I lost my customized slicing profiles.

- The PINDA probe side of the extruder has a crack in it that gives the PINDA probe some play. Not sure when that happened.

- A failed filament re-load caused the extruder gear set-screw to back out, and so I had to re-align the drive gear on the motor shaft and tighten the set screw back down.

First of all, this is what the first layer looks like now: https://imgur.com/bNr7AeR . That is a previous, known-working gcode that was still on the SD card. So Prusa Slicer upgrade changes aren't to blame. Here is a PETG print with that same gcode from a few weeks ago: https://imgur.com/CYU8vKB

I've tried a couple things:

- Ran a dozen separate cold-pulls with the PETG to dislodge any crud left behind by the junky PLA. Also set the extruder temp to 260C and extruded a few centimeters of filament manually. Extruding filament manually looks great, no skipping that I can detect and the plastic falling from the nozzle looks like a proper 0.4mm.

- Before each test print I re-ran the Z Calibration in case the PINDA had moved with that crack.

- Went ahead and glued the crack to stiffen up the PINDA.

- Set the extrusion width to 0.45mm in Prusa Slicer, which matched my old profile. Wound up not mattering since the old gcode also doesn't work.

- Checked that the fans work. They do, but I can't detect if maybe the heatbrake fan isn't pushing as much air as it should and causing a clog.

- Tried increasing extruder print temperature from 240 to 250 and then to 260.

- Tried slowing the print speed down to 80% with and without increasing the hotend temperature.

- Opened the extruder door and double-checked that the extruder gear groove is centered on the filament.

- Went back to clean and then re-position the bondtech gear on the extruder motor. Did not seem to help. Video, the clicking sound is barely audible: https://imgur.com/HjaFkdC

- Ran a temperature calibration. Turns out it's for the PINDA probe, not the heatbed.

- The printer had 3.8.0 installed. I flashed 3.8.1 with Prusa Slicer.

- New print with a better first layer height: https://imgur.com/8wk92vY

- Video: https://imgur.com/0pHRgeq

- I watched this video about the bondtech gears skipping, and took the extruder door off to adjust the rod. It didn't appear to be loose on one side, but it also wasn't centered so I went ahead and fixed that.

- Another print, left side is with stealth mode enabled. In stealth mode the clicking goes away, but the underextrusion does not: https://imgur.com/c7pUpmi

- I went ahead and checked the specs page for my filament, it looks OK: https://prusament.com/spool/?spoolId=ba9b6a7

- I also checked the filament with a micrometer, but it returned 1.732mm which doesn't match the Prusa value.

None of those seemed to help, so I'm looking for ideas on what I could test or try next. Any input is appreciated!

Best Answer by Peter M:

How to adjust first layer calibration.

I think you need to go lower with your first layer.

For your pinda probe, there was a problem that the pinda probe holder, got to hot and melted, search for this, and print a new one with filamnet that can work with a lot of heat, ABS, nylon.

2018 - i3 MK3S Kit with textured, powdercoated plate

RE: Underextruding on PETG prints after using PLA

Check your slicer settings for what kind of printer itis using, the mk3s and not the mmu profile.

RE: Underextruding on PETG prints after using PLA

@peter-m26

Thank you for the suggestion. I double checked, it is using the "Original Prusa i3 MK3S" profile.

2018 - i3 MK3S Kit with textured, powdercoated plate

RE: Underextruding on PETG prints after using PLA

How to adjust first layer calibration.

I think you need to go lower with your first layer.

For your pinda probe, there was a problem that the pinda probe holder, got to hot and melted, search for this, and print a new one with filamnet that can work with a lot of heat, ABS, nylon.

RE: Underextruding on PETG prints after using PLA

@peter-m26

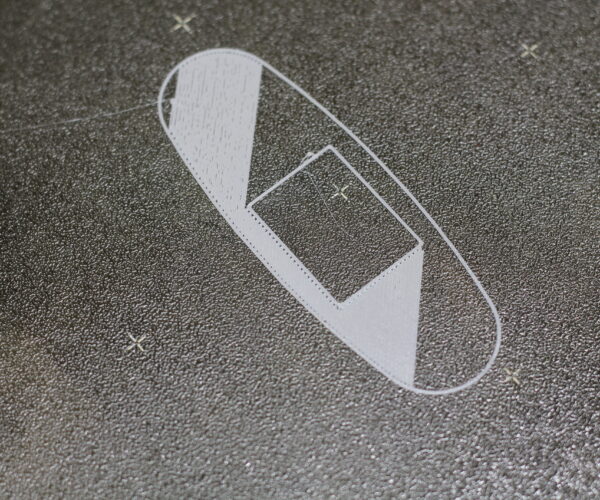

Thanks Peter. The first layer height is a lot lower right now than it used to be back when the printer worked well, so I don't believe it is to blame. This picture is the best one I have right now of showing it:

I definitely plan to print a replacement extruder part for the PINDA probe, but I'd prefer to fix this issue first. Right now I've glued the crack and the probe is holding as solidly as it ever was.

2018 - i3 MK3S Kit with textured, powdercoated plate

RE: Underextruding on PETG prints after using PLA

I went back and really crunched down the layer height and tried another print. It started the infill nicely, but by the time it got to the back of the part it had gaps again.

2018 - i3 MK3S Kit with textured, powdercoated plate

RE: Underextruding on PETG prints after using PLA

OK, I finally opened my eyes enough to take Peter's advice. The first layer was more "squashed" than before I updated Prusa Slicer, but that is because the gcode first layer changed from 0.3mm to 0.2mm, so I had to dial down the Z-layer tune even more, and now everything is peachy.

In regards to the cracked extruder, that turns out to just be a seam between two parts, that appears as though there's a crack. I'm still printing some replacement parts now though.

2018 - i3 MK3S Kit with textured, powdercoated plate