Strange problem with silk filament...

So, I have this strange problem that only happens with silk filament. I am using 3d warhorse silk copper bought from amazon uk and have done all the measurements and inputs in slicer PE.

This is the problem I have:

Normally prints perfectly fine. But sometimes, at some point, the extruder begins clicking some way through the print and the filament begins to clog and remains partially clogged for the rest of the print. Here is what that print looked like when I stopped it:

As you can see, only small flaky blobs remain on top that are easily wiped off. I was printing the silk filament at 220 degrees constant at 0.1mm layer height which I have good results with normally. I also have a bondtech extruder as you can see in the video. You'd expect the geared extruder to push it through... but it still clicks even when idler is tightened. I have a feeling there is some overwhelming pressure preventing the filament from feeding and I am not entirely sure what causes it. My retraction is 1mm and I feel like that could be one of the causes for the silk filament jamming.

Any ideas?

RE: Strange problem with silk filament...

Not used the warhorse silk filament but the silks I have used needed 225-230 degrees to print properly on my mk3. What’s the suggested retraction on the bond tech ? The stock extruder is normally only around 0.6-0.8 so you might be able to go less.

RE: Strange problem with silk filament...

@neophyl

I have no idea on the recommend retraction for the bondtech. Although, I just finished the same print as in the video at 30% size but with 0.4mm retraction. So maybe the retraction was building up pressure over time. Who knows.

RE: Strange problem with silk filament...

Hello

I face the same phenomenon with Spectrum Silk PLA on my MK3s. Never had problems with my printer! Also no problems with Wanhao Silk PLA. Tested with two different filament rolls from Spectrum Silk PLA. I even change the Nozzle.

The funny thing is, that in Vase-Mode i had no problems.

I will try to slice now with higher temperature 225-230 °C.

Greetings

RE: Strange problem with silk filament...

I used to be a big user of Sprectrum filaments but in the past year or so the ones I have bought have shown reduced quality, been badly spooled etc.

Last roll I got from Spectrum was their tropical green silk. Absolutely unprintable. I was getting all sort of skips and partial layers printed. No trouble with other silks either like mkoem.

Came back to it printing in midair. After checking the filament, the roll had a section that was nearly 3mm diameter and of course that was jammed in the extruder. It looked liker a splice between 2 rolls, this in the first third of a roll. I checked the diameter at other points and it was over 1.8mm in several places. Basically their quality control seems to be non existent now. It was this variability that was making the extruder skip. Ive still got the rest of the roll but I just don't trust it to print with.

They went from my go to supplier (I was buying direct from their factory at one point) to avoiding them.

RE: Strange problem with silk filament...

Hello

I could print the 3d-Benchy with Spectrum Silk PLA on my MK3s with higher Temperature without any problems:

"Filament Settings": "Generic PLA"

Only modifications on the Filament Settings:

"First layer": 230°C and "Other layers": 225 °C

Greetings

RE: Strange problem with silk filament...

Hello,

test it with "Max Volumetric Speed" 2.5

You can change it, when you click on Expert, "Filament Settings"/Advanced

Since the filament is now printed more slowly, the nozzle also stays longer on the other layer. So you can use the specified temperature of the Silk Filament. With Silk filaments it is not advisable to increase the temperature above the specification anyway.

On Youtube you can search for "darkwing dad silk". He has made several videos about silk filaments. Among other things, he also briefly discusses the composition. His settings in Cura are quite a bit, so I don't want to give them all.

In summary: print slower, reduce "Max volumemetric speed". Leave temperature at manufacturer's specifications.

Many greetings

juck.

Translated with www.DeepL.com/Translator (free version)

RE: Strange problem with silk filament...

Hello Juck

Thank you for the link to the Youtube Video!

That the volumetric speed has something to do with the issue would also explain, that there was no problem in "Vase Mode".

In vase mode the volumetric speed and volumetric flow rate is always the same and do not change much over the whole print.

Because also with higher temperature i faced the problem sometimes, but could not figure out, that the problem appears on some specific volumetric speed.

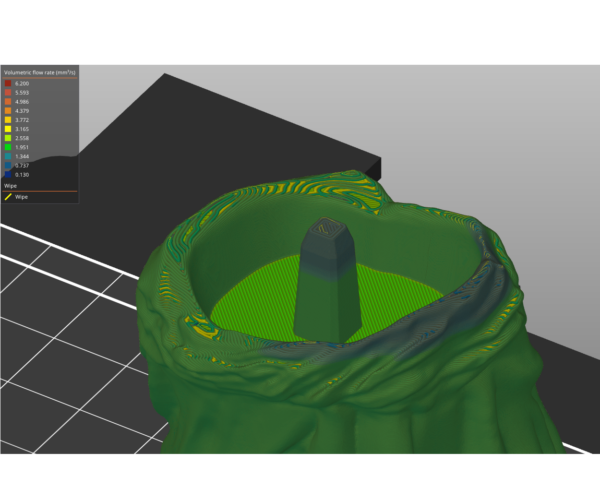

I try to get some feeling and knowledge about that, by checking in the Prusaslicer under "View" the "Volumetric Flow Rate" appearance on the sliced model.

Greetings

RE: Strange problem with silk filament...

Now it is clear: it has devinitivley to do with the volumetric flow rate as you can see in the pictures below. It is not anymore a silk PLA, but also a not "standard" PLA. It is MarbleJet from PM. Maybe anyone know how to adjust these settings in Prusaslicer (my Version 2.3.3). I tried to change some speed parameters, but could not manage to increase the volumetric flow rate in this section of the model shown in the pictures.

The printed model with the failure:

Prusaslicer View Volumetric flow rate:

RE:

Hello BeyondCollaboratio,

unfortunately I didn't get a message that you replied. Therefore, I saw this only by chance.Where your print breaks off is a very short layer. The material did not have time to cool down sufficiently. It would be best to wait there 1 or 2 seconds before printing the next layer. You can also try to print the layer with 100% filling exactly there.

Without modifier it is faster this way:

Print Settings

Infill

Advanced

"Solid infill threshold area:"

First set 10 and increase by another 10 until the area is 100% infill after slicing.

You can also adjust the speed with a height modifier.Slice it first in your selected layer height.then find the first layer where this small layer starts and where it ends. Write it down.Then go to "3D Editor View" at the bottom left again and select the whole object so that it turns green.Then you go right at Editing on "Height Range Modifier". Then you set the values, in which range the print should slow down.Then you go again to Editing, but this time at the Range. Then "speed" and select "external perimeters" "infill" "perimeters" There you can test for the external perimeters 10, for perimeters 25 and for infill 25.This should then print a little slower.What you can also do, look at your component fan. Maybe it is clogged with dust.

LG

juck.