RE: Scratched rods from linear bearings

The distances between the rods on my assemled printer are:

left: 36.95mm

center (at the extruder): 36.74mm

right: 36.99mm

So yeah, there's definitely something wrong there. Have to admit though, that I tensioned the screws pretty much as tight as they would let me. So I'll probably have to play with that a bit.

RE: Scratched rods from linear bearings

@vojtech:

Thanks for all the suggestions ans explanations! The grease looks promising... But I suppose, there's no way of buying less than a whole kilogramm of that stuff?

No, there are larger packages, though, like 15 or 50 kg. 😀 I suppose I could send you some of mine, I don't expect I'll ever use the 1kg package I have bought.

The Prusa Mk3 is probably the best printing and easiest to use printer you can get for 800€ on the planet. But that doesn't mean there isn't cost cutting visible on every single part of it, with the goal to fit into the budget and still make a margin to feed the company that makes it. Bearings, rods, PSU, CPU, motors, printed parts, even the frame, everything is just barely good enough to work well. A perfectionists dream or nightmare depending on whether he has the budget to tinker and improve.

I've only done the excercise with Mk3 parts, but @butterworthdesign checked the rest HERE. The desings are all alright.

RE: Scratched rods from linear bearings

Another possibility would be anisotropic shrinkage of PETG in the X/Y vs Z dimensions while printing. Parts that I printed myself had the same issue as the ones received from Prusa. Can someone else verify the differences on their printer?

I just checked. I do not see any significant difference on my Mk3 (with S-extruder back/carriage). Inter-rod spacing was only ~0.15mm different next to the extruder (with it in the middle) vs the distance between rods at the end.

RE: Scratched rods from linear bearings

By the way, this is how my X-end looks today with the aluminum parts (*). The caliper now says 36.99-37.01 along the whole length of the rods.

(*) And a Bondtech extruder and a 0.9° pancake, GT3 belts, and re-twisted cabling with teflon and nylon tape, reverse bowden, Trinamic X stepper, and ... 😉

RE: Scratched rods from linear bearings

Yup, I have an X-rod that looks just like that here before it got replaced.

RE: Scratched rods from linear bearings

Those bearing are easy to damage, at work I have install many kind of linear bearing mostly SKF and you really need to align them perfectly square before trying to insert them. I will see If I can design an aligning pin so its easier to start the insertion. Those high grade bearing have rod or temp rail to help with insertion (they sell for a lot more also lol)

I am planning to remove them to grease anyway so I can test it and share the result. Any damage to the cage, introduction of particle or popping out ball can cause them to stop and do those strike on the rod. As I plan to dismantle to grease, I am hesitating to order some Misumi bearing and Rod my Y axis have play since the beginning, it's probably roll strait under its own weight... But as i dismantle anyway I would prefer to do upgrade if possible... Here what I want to buy.

Anyone have recommendation to replace the Y bearing holder and maybe the ty-wrap Y Holder ?

- 10x LMU8 Misumi

- 2x PSFJ8-320

- 2x PSFJ8-330

- 2x PSFJ8-370

RE: Scratched rods from linear bearings

and you really need to align them perfectly square before trying to insert them.

I don't really understand what needs to be aligned to what. Can you explain?

RE: Scratched rods from linear bearings

@cordilon

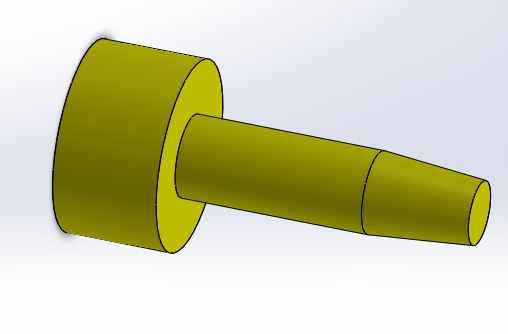

Yeah of course, I mean Allining the bearing before starting to engage them on the rod its hard just in the air to be perfect. So i made a quick picture of the kind off tool I have seen and use in different Linear bearing or High pressure Oil seal insertion kit .

You usually have the tool on the bearing already, but its made with taper to help safe insertion. Then you press the yellow tool on the tip of the shaft so you have one axis aligned. Then you center the tool and the shaft, and slowly engage the bearing while keeping the pressure on the tool.

RE: Scratched rods from linear bearings

@frank-the-rock

Thanks for the illustration, I think I get it now. Still I'm kinda scratching my head here if this is really necessary. I took a standard LM8UU bearing apart just recently and as far as I can tell they consist only of the metal housing, a plastic insert, the actual balls and the dust covers. It's difficult for me to imagine how one could damage any of those severly when pushing a bearing onto a rod slowly and gently... I mean it should somewhat self-align, right?

RE: Scratched rods from linear bearings

@cordilon

Yeah if you have a little dexterity/mechanical skill yeah should not be a problem! Just one false move and you can damage one. I know I have done it at work, then you throw it in the recycling and install another lol easy . Reading recently all the post about scratch rod, made me think about what could cause this, so decided to add a few word of advise if it can help someone. Bering is easier to break then it look, just some surface damage on the little ball can get them to stop roling and grinding your rod sadly. Then you have metal particle in there and it start to affect them all . And that's not even taking care of tolerence mismatch possible and quality.

Sadly It's not self aligning the only play you got is the tolerance i think. the dust cover does help get it co-centric but one could push off center ...

To much Haribo can give you a lot of strength you know 😋

RE: Scratched rods from linear bearings

To much Haribo can give you a lot of strength you know 😋

I'm a vegan, so no Haribo for me anyway 🤣

But thanks for the info, I'll definitely be even more careful when I finally decide to order and install the Misumi bearings and rods!

RE: Scratched rods from linear bearings

I second you on the sewing machine oil as well (: I've been using it since 2018 without a problem. Just finished talking with Prusa customer support and the person was saying that the technicians at Prusa use sewing machine oil too. I'm not sure what that says about the other oils and greases, but I suppose it means that it's nonetheless a great choice.