Reducing noise/vibration

Hello all,

My printer has become quite loud over time. Particularly, the Y axis movement and extruder assembly.

I believe a significant portion of the noise is coming from the part cooling fan shroud, however I am at a loss of how to eliminate that noise. Have any of you had success with silencing it?

Additionally, I believe the Y axis is somehow introducing vibration at higher speeds, but at lower speeds it's quiet. I've lubricated the bearings and it moves smoothly by hand, so I'm unsure what to do in that regard.

Cheers from Canada.

RE: Reducing noise/vibration

I did several things:

- Replaced the feet with the new square ones on the Prusa Store.

- I put it on 18x18" tile that has silicone feet under it.

- I have it in a lack enclosure.

- I printed feet for the lack table that allows me to add antivibration pads in them

--------------------

Chuck H

3D Printer Review Blog

RE: Reducing noise/vibration

Keep bearings well lubricated ... they make a lot of the noise as the axes move. Y wears a lot more than X, too; and the extra play as the bearings wear add noise, and cause resonances to ring out. And little things, like the sheet touching the stop screws can buzz quite loudly if the sheet isn't firmly touching them; or the LCD touching the plastic case is another rather loud source. But in my experience the worst noises came from the filament spool rubbing on the holder: not quite a squeak, but random and loud enough at the prefect pitch to annoy.

ps: I did add rubber dampers between the wall and my print table that reduced vibrations a lot; probably didn't do much for general noise.

RE: Reducing noise/vibration

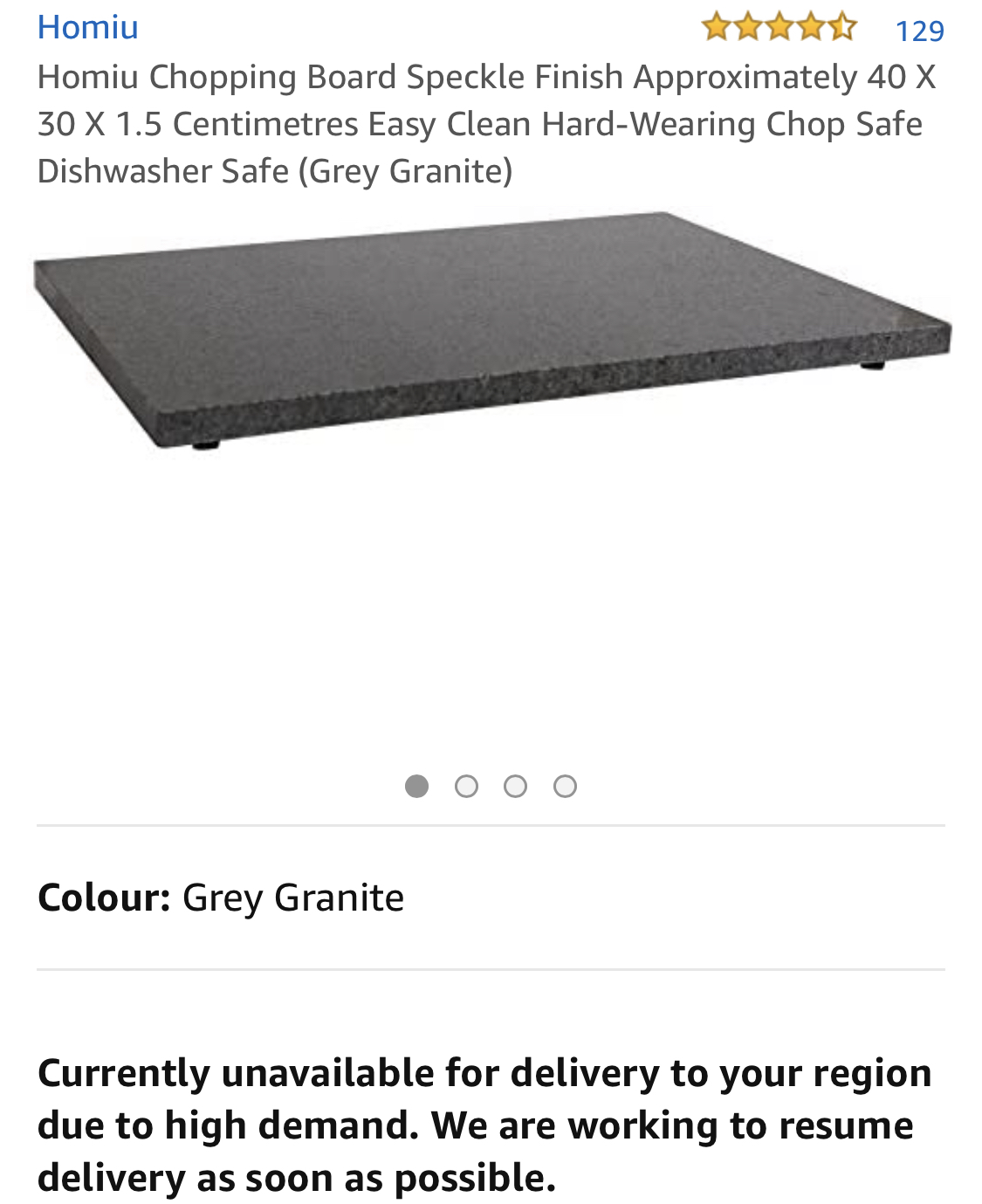

Biggest difference to noise for me was when I put the printer on a granite chopping board, it made a huge difference. Every move was being amplified by the large table top and even transferring into the wooden floor the table was standing on, the granite chopping board has soft squidgy feet and because of the solid mass and soft squidgy feet, it isolates the printer from the table very very effectively.

As a quick test, but only a test, fold a blanket up a few times, ideally place a glass chopping board or other solid surface on this and place the printer on top and move the axes about, see if this silences things enough, if it does, then look at a slab or granite chopping board, and soft squidgy isolation.

Don't run the printer on the blanket for long and never unattended, the fibres and dust will get into your printer, as well as there may be an increased fire risk.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Reducing noise/vibration

Biggest difference to noise for me was when I put the printer on a granite chopping board, it made a huge difference. Every move was being amplified by the large table top and even transferring into the wooden floor the table was standing on, the granite chopping board has soft squidgy feet and because of the solid mass and soft squidgy feet, it isolates the printer from the table very very effectively.

As a quick test, but only a test, fold a blanket up a few times, ideally place a glass chopping board or other solid surface on this and place the printer on top and move the axes about, see if this silences things enough, if it does, then look at a slab or granite chopping board, and soft squidgy isolation.

Don't run the printer on the blanket for long and never unattended, the fibres and dust will get into your printer, as well as there may be an increased fire risk.

What type of Granite Chopping board? Can I see a picture?

--------------------

Chuck H

3D Printer Review Blog

RE: Reducing noise/vibration

But before spending any money, check if it is noise being conducted into a surface or the actual printer.

If your careful you could lift the printer slightly whilst it is printing using the steel frame, and if the noise drops off dramatically, there's your answer, if there is not much difference, then you won't be wasting money on something you may not need.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Reducing noise/vibration

Thanks. I just wanted to see what you were talking about. If I buy more printers, I will consider it.

--------------------

Chuck H

3D Printer Review Blog

RE: Reducing noise/vibration

With the part cooling fan, I do what I have always done with noisy fans of this type of construction, peel the sticker off the back and put one drop of oil on the spindle but make sure it gets behind the plastic clip which holds the impeller shaft in the bushing, you will have to remove the fan and hold it horizontally, but be careful of the wires. I use my usual Singer sewing machine oil. It will become rattly again in due course, so just do the same again. There will come a time where no amount of oil will help, it is just the nature of this type of fan and it will need replacing. They are cheaply made and tolerances are not great and they certainly are not balanced at the factory or anywhere for that matter!.

It does not really help that this board requires a 5v 3 wire type fan as these are not so common.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Reducing noise/vibration

Thanks for the wonderful replies. I will try all of the suggestions and hope for the best!! Also, the granite cutting board looks quite nice.

RE: Reducing noise/vibration

But before spending any money, check if it is noise being conducted into a surface or the actual printer.

If your careful you could lift the printer slightly whilst it is printing using the steel frame, and if the noise drops off dramatically, there's your answer, if there is not much difference, then you won't be wasting money on something you may not need.

I’ve determined my noise is in fact the vibration on the large table my printer is on. Unfortunately, that granite chopping board isn’t available to be shipped to the US currently:

And as a slap in the face, there IS a separate US listing for presumably the exact same product... albeit at a MUCH higher price of $75.89 plus and additional $38.76 shipping (total price of $114.65 US). That’s nearly $100 above actual price!

I guess I’ll have to find alternatives! Shouldn’t be too hard, I just found this level of price gouging comical.

RE: Reducing noise/vibration

With the part cooling fan, I do what I have always done with noisy fans of this type of construction, peel the sticker off the back and put one drop of oil on the spindle but make sure it gets behind the plastic clip which holds the impeller shaft in the bushing, you will have to remove the fan and hold it horizontally, but be careful of the wires. I use my usual Singer sewing machine oil. It will become rattly again in due course, so just do the same again. There will come a time where no amount of oil will help, it is just the nature of this type of fan and it will need replacing. They are cheaply made and tolerances are not great and they certainly are not balanced at the factory or anywhere for that matter!.

It does not really help that this board requires a 5v 3 wire type fan as these are not so common.

That's a good decision for first time, but sometimes it is easier and faster to replace it.

RE: Reducing noise/vibration

I used to use the Oil filled period to keep me printing while I ordered a replacement (Well.... that is until I ordered a batch of fans, I have six printers, so will need fans sooner or later whichever way it goes... ) 🙂

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Reducing noise/vibration

@scyanix

GASP!!! You're shopping in the wrong market!!

"12 in. x 12 in. x 1.5 in. Antique Terracotta Square Concrete Step Stone" $1.49 @ Home Depot or pretty much any other building supply or hardware store. Add a few pennies for something soft like glue-on feet, a piece of carpet pad foam, etc. and you're home free. Probably better off - more mass yields a lower natural frequency, which conducts poorly to the table/floor. Softer feet have the same effect, until the printer begins to dance around scaring you to death.

If you want something bigger, 16"x 16" is another standard size - probably $3 - $4 each.

Then, build an enclosure that covers the printer and paver (enclosure sits on table so there is no direct contact path for vibration), and you can sleep next to it.

I have not tried this (just popped into my nearly empty head), but maybe clamping/screwing the printer frame to the paver (three points only, so it doesn't warp the frame) would keep the printer frame from vibrating at any high frequencies. That would assure that the print bed is not singing to the local audience.

RE: Reducing noise/vibration

Stefan of CNC Kitchen has videos on this topic that are well worth watching:

Key points are:

-

The trick to reducing printer mechanical noise is to increase mass.

-

Mounting the printer on a heavy surface such as a 17x17 inch paver stone adds mass.

-

Acoustically coupling the printer to the mass maximizes the vibration dampening effect.Do not isolate the printer from the base. Felt non-isolating feet work well.

-

De-couple the printer mass from the resonating surfaces. Isolating foam or Sorbothane feet work well to keep any remaining vibration from being transmitted into the flat supporting surfaces.

I paid something like $7 for a 17x17x3 inch paver stone to mount my Mk3. You definitely don't need anything expensive, and more mass is good.

RE: Reducing noise/vibration

Noise abatement program in what think are impact order

1. Put a large zip tie around the Y motor pulling it more tightly against the back frame. The bracket leaves the motor breath-width from the frame, and it vibrates.

2. Put a zip tie around the control box case. That thing buzzes randomly and the zip tie, while partially obscuring the display, makes the buzz stop.

3. Print out a set of squash ball feet for your printer. These quiet nearly all of the transmission noise to whisper quiet after 1 and 2 above.

4. If you do put it in an enclosure or on a hollow space like a table top or cabinet, a lot of the noise will seem to come back - this is resonance. I cut squash balls 1/3 of the way across and put 4 under my enclosure. Instant quiet. The flat spot on the balls keeps the whole thing from rolling around like it was on marbles (cheap squash ball feet)