Problem with extrusion consistency

Help! Though I managed to get past the calibration problems I had by loosening some screws, this one doesn't seem to be fixed by loosening or tightening screws. It would seem that my extruder is skipping/slipping on the filament, but I can't seem to get it to stop. I'm still just printing PLA, with the spool of silver that came with my printer, nothing fancy. While I've tried a variety of things, I'm a complete newbie to 3D printing, so would very much appreciate assistance from the Prusa experts. I've been reading through the forums and web site, but I'm not finding help for my problem, so decided to post.

Here's a couple videos I took. WARNING! I speak during these videos. 😉

I've got some photos as well, if requested.

Quick video showing first layer calibration with the skipping exhibited only during the purge line. 3.5 minutes

Longer (7.75 minutes) video of printing an actual object

If there's a thread or FAQ/KB article that addresses this issue, please post a link.

Thank you!

Re: Problem with extrusion consistency

Have you checked how leveled is your bed? Might be getting to close to the bed and making that noise and that also would explain being so close that it sometimes blocks the nozzle. Use the great Octoprint plugin posted in this forum to visualize your bed level. You might have a partial clog if suddenly less plastic comes out in the middle of the print.

Re: Problem with extrusion consistency

Hi Mr Flippant,

at this instant I don't have any suggestions to why your extruder is slipping.

your initial purge line seems very heavy compared to mine.

you say you have tried adjusting a lot of things... what is the current status.

is the printer back at standard setup? no changes, no adjustments?

is the slicer Slic3r PE?

is it using standard settings?

which firmware are you using? (probably best using the latest available. I am using 3.2.1 )

what slicer version are you using (again, latest available, is probably best) use with a fresh profile Prusa PLA or Generic PLA at 0.2 layer height!

are you using the correct slic3r I use both the mk3 and the Mk2mmu versions

If I inadvertantly slice in mk2mmu version and try to print on the Mk3, the prints don't go well...

as you noticed, peering into the bondtech chamber to confirm movement, is not easy...

have you seen the visualiser idea?

https://www.prusaprinters.org/visualize-extruder-motor-movements/

the visualiser lets you see extruder movement from the outside...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Problem with extrusion consistency

RESOLVED!

As always, thank you very much, Joan! 🙂 Your knowledge and patience in delivering it is saintly. 🙂 Don't ever stop. 😀

After upgrading to the latest firmware (was on 3.2.0), and installing the latest software for slicing (I'm still a super-newb and just use Prusa Control for the ease of use), and slicing a new copy of the model, I went to XYZ calibration. No problems there. Then I did the First Layer Calibration (FLC) and had problems. It was extruding even more poorly. The purge line didn't even print, and the beginning of the calibration line was missing as well. It was then that I realized that this is not a setting issue. It's clogged!

I just never thought that a brand new hot end assembly would get clogged so soon, and with practically no printing. I guess all the time heating up and cooling down while printing almost nothing during my calibration woes over the last couple weeks took its toll, and caused a clog.

I tried the unload/reload filament thing, and it still wasn't flowing well, so I unloaded and heated it up to 250 (per KB article) and used the needle to work things loose up in there. Then I reloaded the filament and it flowed quite nicely (from my newbie perspective). I deemed that a success, and ran a new FLC. This went well (though I can see the mesh bed leveling isn't working well, since I have better "squish" in some areas of the print bed than others, but I'll deal with that later), so I decided to try my test object.

HUZZAH! Successful print! I think I might have heard a skip at some point, but that also could have been something on my table knocking/falling during one of the more vigorous parts of the print run. I'll definitely keep an eye on it.

You learn something new every day... and with 3D printing, often you're learning a multitude of new things each day. 😉

Thanks again! Hopefully some newbies reading this can Learn From My Fail.

Re: Problem with extrusion consistency

Good to hear you resolved the immediate issue...

when you are ready to pull more hair out, you can play with Bed Level Correct, under the Calibration menu, that allows you to adjust,

Lesf side,

Right side,

Front and,

Back

and if that's not enough, try searching on Hyperfine Bed Levelling!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Problem with extrusion consistency

Hehe, thanks! I'll cross that bridge when I come to it. I can't even see it in the distance yet. Must still be over the horizon. 😉

Bed Level Correct, however, is right up ahead. 🙂

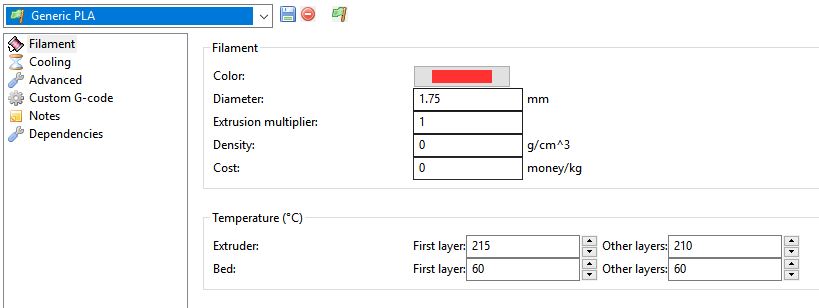

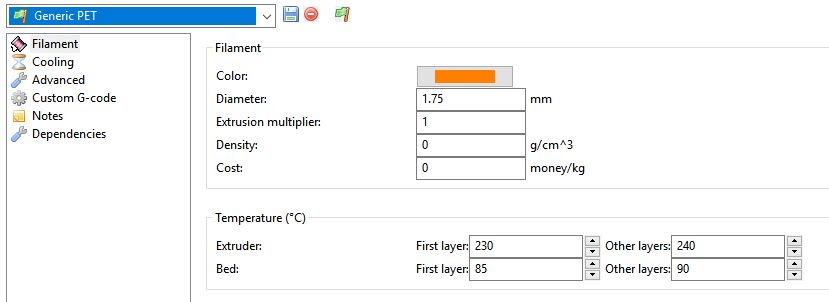

A question for you (and anyone), though, is why does the temperature drop after the first layer (or two)? I noticed that the default is 215c, but then later on it went down to 210c. I imagine it has something to do with the filament cooling properly during the later layers, but I wonder if that might be contributing to the clogging I get. I did an extruder motor visualiser print, and noticed the skipping again, though less so than before, and I'm worried that it will get worse until a bad clog again. Assuming the cooling fans are working properly, why wouldn't you want it to print at 215 the whole time? Or if higher temps are important for good print bed adhesion, why not print the first layer at 220c and then the rest at 215c?

Re: Problem with extrusion consistency

Hi Mr Flippant,

for PLA the first layer temp is typically higher, to promote good adhesion

For PETG, the first layer is Typically, Lower, perhaps because PETG adhere's too well

other filaments tend to have the same temperature for first and successive layers...

PLA usually has the fan on after the first layer,

Petg usually has a lesser fan setting after the third layer,

ABS doesn't usually have the fan on.

ABS can be difficult to use without either a stable room temperature around 30Celcius, or a cabinet with similar conditions inside it...

if you don't have an absolute need for ABS, I suggest you steer clear...

I found it hard to work with, and it gave me chest problems from the airborne particles during printing (purely personal experience!)

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Problem with extrusion consistency

Yeah, I'm definitely sticking with PLA until I'm much more experienced in troubleshooting... AND I have a specific need for those other materials.

Re: Problem with extrusion consistency

There is an article on Reddit, https://www.reddit.com/r/3Dprinting/comments/8hq4at/is_there_a_fundamental_problem_with_the_prusa_i3/#bottom-comments , that describes this problem.

I have found that my mk3 clogs when doing a Benchy or Castle print. It happen when there is rapid retraction going on and you hear a click as the gears slip on the filament. If I am laying down long extrusions there is no issue, but if I get to a part of the print with a lot of detail that requires quick, rapid, continuous, retraction the hot end clogs and does not extrude any more filament.

The Reddit article is pointing to a flaw with the MK3. I have replaces the PTFE once and will try it again since I got the tube directly from Prusa.

Is there anything else I should try? My firmware is up to date, the failure is with the test prints that come with the unit, and I am using Prusa filament.

Thanks.

Russ

Re: Problem with extrusion consistency

That explains the cause. Then, when it's in that condition, fast printing causes it to happen most often. While running a print for something with a large infill area, I noticed how much faster it was printing the infill, and it skipped like CRAZY during that part. While it might not be a big deal for the infill to be ugly, it also would result in a bad looking roof layer.

This has finally caused me to jump ship from Prusa control to Prusa Slicer for the MK3 so that I can tweak the settings. I turned the infill speed to almost the same as the perimeter. I also turned the heat up a few degrees (back to 215 for the upper layers, and I lay it down at 220) for the nozzle. I've still seen a skip or two, but nothing like when it was trying to really push the filament out fast.

If I tweak settings in Slicer, will they be used in Prusa Control? I like the simplified interface, but want to be able to use my customized settings.

Anyway, I feel that this is a bit of a stop gap solution. If the printer was meant to be capable of printing infill correctly at such high speeds, why can't mine? I have an idea of something to try, but don't really want to dismantle it again when I've just gotten it working again.

Re: Problem with extrusion consistency

never mind. even at slower speeds it is skipping again.

I guess I'll go ahead and do the thing I was thinking of... which is to re-do the nozzle/heat-block/heat-break assembly to make sure the nozzle is right up against the head block. That's the only thing I can think of that I haven't already tried. 🙁

Re: Problem with extrusion consistency

I guess I'll go ahead and do the thing I was thinking of... which is to re-do the nozzle/heat-block/heat-break assembly to make sure the nozzle is right up against the head block. That's the only thing I can think of that I haven't already tried. 🙁

You don't want the nozzle tightened up to the heat block. This will lead to more issues. The nozzle needs to be almost flush with the heater block but snug to the heat-break. This documentation from E3D has all the information.

Re: Problem with extrusion consistency

I recommend that you install a new nozzle. It certainly sounds like you're having a clogging issue and nozzles are cheap (albeit a bit of a pain to replace).

If you do buy a new nozzle, make sure it's a genuine E3D. You can get them on Amazon:

Re: Problem with extrusion consistency

I'll definitely order a new nozzle through Amazon.

My nozzle is currently a good 1/8" away from the heat block. The instructions you linked are pretty much exactly what I was going to do. But, if that's not going to change anything, I might as well wait for the new nozzle and THEN do it right.

I'm just REALLY frustrated by this problem. Slowing things down didn't help for long. If it's caused by the nozzle proximity to the heat block, or even a poorly assembled hot end assembly, then I'm kind of mad at Prusa for sending me a poorly assembled product. I bought Prusa BECAUSE I wanted to have LESS of stupid crap like this.

Re: Problem with extrusion consistency

If you do buy a new nozzle, make sure it's a genuine E3D. You can get them on Amazon:

We have tested a few different "brands" of nozzle and have not noticed any difference to a standard E3D, so if you decide that you would like to spend 20 cents instead of a few bucks then give the J-Head brand a go. Not had any issues with them. A (brass) nozzle is a nozzle as far as I can see.

Re: Problem with extrusion consistency

MrFlippant,

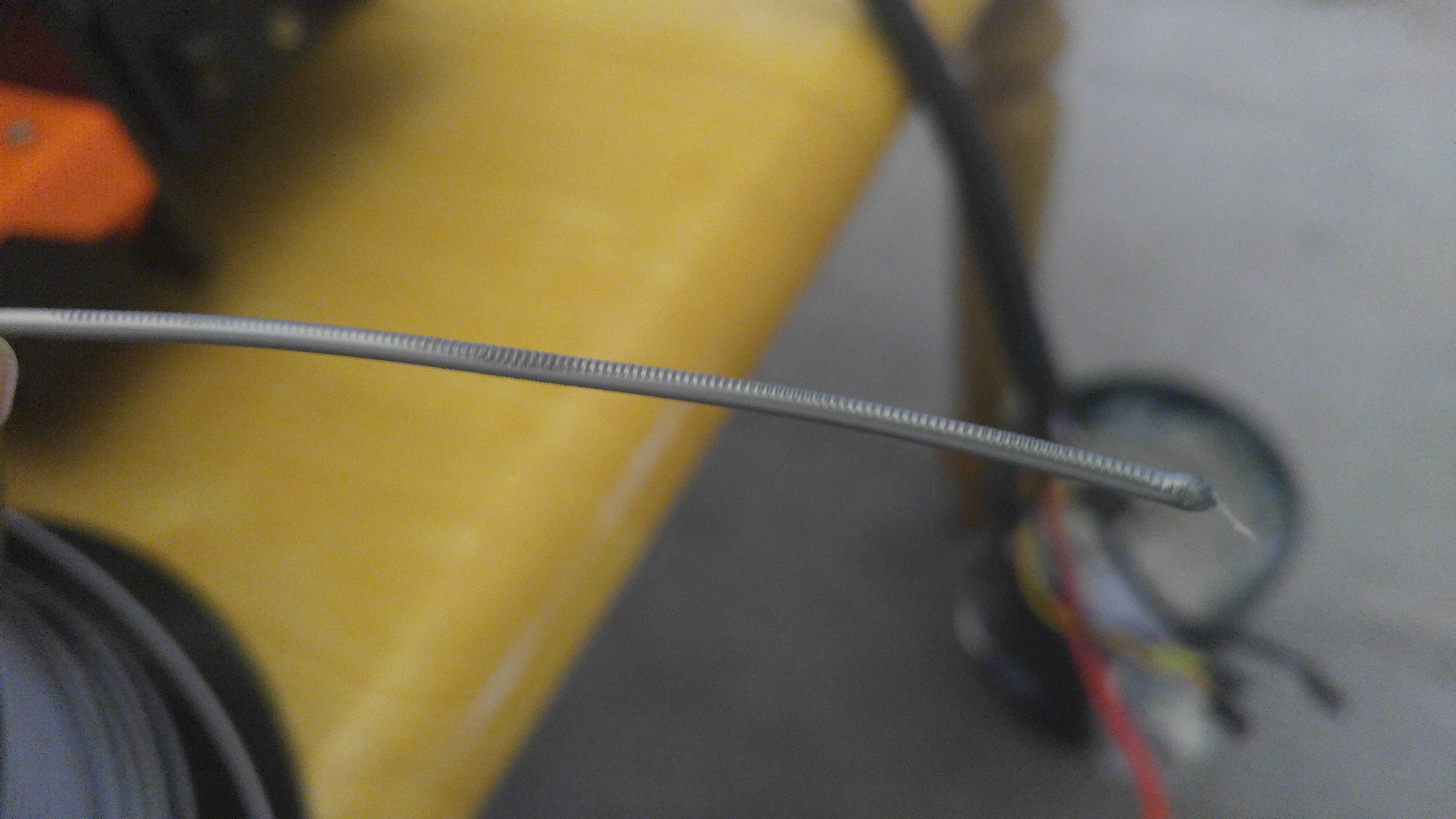

Can you unload the filament and post a picture of the groves left on the filament. After looking at your video again it looks like the tensioner screws are too tight. I know you stated in the video that you loosened and tightened them but it may not have been enough. Also, I'm wonderering if the thermistor might be out of spec and reading the temp wrong? At 215 during the First Layer Calibration I would expect to see some oozing of PLA from the nozzle but in your video I didn't see any.

Re: Problem with extrusion consistency

Pending other suggestions, I've ordered a replacement nozzle, and will install that when re-configuring my hot end assembly per the previously linked guide.

I'm certainly open to additional suggestions, as I'm not very confident that this will resolve the issue.

Re: Problem with extrusion consistency

Pending other suggestions, I've ordered a replacement nozzle, and will install that when re-configuring my hot end assembly per the previously linked guide.

I'm certainly open to additional suggestions, as I'm not very confident that this will resolve the issue.

I'm gonna be a broken record and point out my ever-so-loving-fix-all-solution-that-seems-to-work-almost-half-the-time.

What does the filament touch going through the printer.

1. PTFE tube (above filament sensor)

2. Bondtech Gears.

3. PTFE tube (below bondtech gears, going into E3D Heatsink)

4. Mk3 Heat Break.

5. Nozzle

I honestly believe your problem is one of those.

1. This isn't your problem. It never is.

2. Other than possibly being over-tensioned, which COULD contribute to your issues, I doubt this is the root cause. (Over tight, causes extra torque on the motor, and can lead to skipped steps, and/or clicking noises)

3. I highly doubt this is your problem on a brand new printer. These can get worn out, and funky over time... but yours in a new printer.

4. Go read https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/filament-jams-in-heatbreak--t15788.html

5. You could have a nozzle jam. If your printer shipped with a "flake" of PTFE from the PTFE tube... it *WILL* jam your nozzle. Pushing it around with a needle will dislodge it, but not "pass" it. (meaning it will re-jam)

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Problem with extrusion consistency

So, what you're saying is, get a MicroSwiss heat break? 😉