Print failures galore

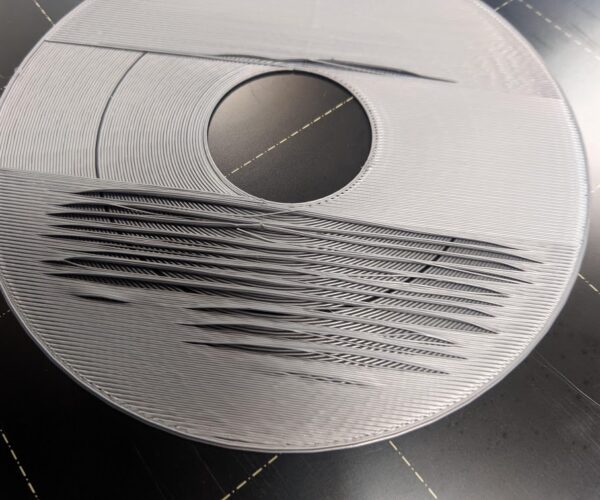

I ran the MK3s for months without issue, getting some great prints. However, a few weeks back it started acting up. Replaced some bearings and cleaned rods solved two issues. My latest issue is something odd. I can no longer get the great bed adhesion I had before, but after multiple calibrations, I got something I figured I could try. First layer not perfect, but this second (or third?) layer I have no idea why it's not happy. It seems Z isn't moving the correct amount? Same file printed 1/2 way OK last week.

So the other issue I have: prints aren't completing. The feed gear eats up the filament, presumably b/c of a blocked hotend. I discovered the PTFE tube bulged out so it had a shoulder on it. Looked like it was formed that way, but apparently not (photo tomorrow). I replaced the tube and ended up with the same bulge within 10 minutes again (though not as pronounced). Third tube is in there now, and I'm getting the print below. Temperatures are reporting 215C.

I intended to replace the nozzle in case that was the issue, but it just won't come off, even at 260C+. I can't get the screw out to remove the heating element either to work on the workbench. I loved this printer...until I didn't! I appreciate any insight. All of this has been run with Prusa filament. I did run some TPU not long before my bearing issues, but I've run cleaning filament multiple times so I'm not thinking its the TPU.

RE: Print failures galore

I have yet to even receive my MK3S kit but i do have some experience 3D printing. SO, take my words with some salt.

Have you looked inside your heater block for any contaminants? I know you ran cleaning stuff through but as I'm a part mechanic, nothing beats actually looking.

How is the clearance/tolerance between moving parts? Anything hooking up? Maybe the heat is leaking out and causing your tube to melt.

Remember, if something is happening and you think you fixed but it's still happening, you didn't fix it.

From your picture, it looks like maybe your nozzle could be too low. Is your printer near an AC vent? Have you dried your filament? From doing a ton of research, I've learned just a bit of moisture absorption and print quality goes down the gutter.

These nozzles are brass so they can contract and shrink. I havent heard many people doing this (also havent looked), what if you put the assemble in the freezer/ fridge for maybe 30 mins. Cause the nozzle to shrink and then try to remove. I have done this before but with other machines. The issue with heat is the nozzle with expand into the block, creating sometimes a tighter fit.

Bed Ahesion; i read that acetone and revitalize the adhesion. But i dont think you do it with the powder coat bed.