Re: Playing with the air nozzle design

Hi RHDreambox! I love it that you are teasing a bear version of your nozzle design. How is progress going on that fork? Is performance similar?

Re: Playing with the air nozzle design

Hi RHDreambox! I love it that you are teasing a bear version of your nozzle design. How is progress going on that fork? Is performance similar?

Hi stahlfabrik, nice that you are interested in it. Do you use the gresaun extruder or do you just want to test the nozzle?

I think those who have tested it are pretty positive about it. But I might be able to improve it a little bit, or make a whole new model.

I have previously posted it here ...

https://github.com/gregsaun/bear_extruder_and_x_axis/issues/20

but here is a faster link

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

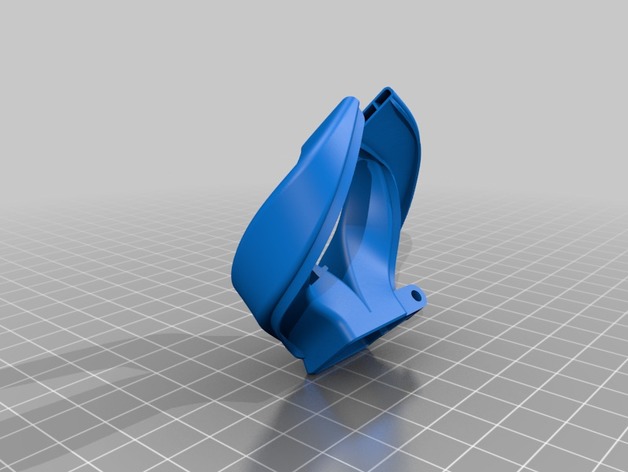

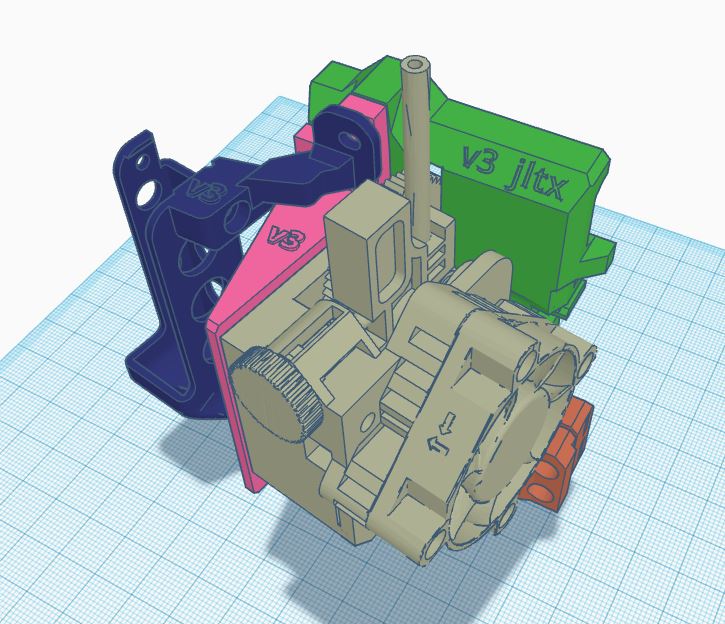

I thought I should mention the so-called "Omega" design being worked on by @jltx to go with his Skelestruder, which does not seem to have been mentioned in this thread yet. I'm in the process of converting my Mk3 to Skelestruder with this air nozzle, so it will be interesting to see the results.

Re: Playing with the air nozzle design

Yes, I'm also jumping on the "Omega"-design.

It gives a wonderful view under the nozzle and the shroud is less covering the printed part. I'm also using an high powered axial fan instead of the blower.

This thing is still work in progress, I will optimize the mounting of the shroud. Unfortunately, the extruder cover is not stock Prusa or BEAR anymore, but it will give more space for natural cooling the hotend. The hotend is not covered with these mounting nuts.

Thomas

Re: Playing with the air nozzle design

Hi RHDreambox! I love it that you are teasing a bear version of your nozzle design. How is progress going on that fork? Is performance similar?

Hi stahlfabrik, nice that you are interested in it. Do you use the gresaun extruder or do you just want to test the nozzle?

I think those who have tested it are pretty positive about it. But I might be able to improve it a little bit, or make a whole new model.

I have previously posted it here ...

https://github.com/gregsaun/bear_extruder_and_x_axis/issues/20

but here is a faster link

A nice thank you! I was not aware that there is already a version to be downloaded. I am currently printing the bear extruder parts and will to the transition hopefully soon.

So I am not using the extruder yet - but I will soon and do not want to miss out from the cooling that your R3 nozzle provides:-)

Re: Playing with the air nozzle design

Have you considered a 360° laminar flow nozzle? It wouldn't be easy, and maybe impossible in this scale, but it would be interesting to try. Think of it as designed like the Dyson fans but angled to create a "focal point" pointing up at the tip of the extruder. You would have to change the fan but that shouldn't be hard (if you can find a small impeller type fan that is).

Re: Playing with the air nozzle design

I'm curious how this design stacks up against the newly-released Mk3S cooling shroud. It appears to have undergone some drastic shape changes.

Re: Playing with the air nozzle design

It appears to be mostly just blowing straight out of the end of the fan down onto the printed piece with a small amount of bleed being directed from the sides, it's less focused at one point but more sort of area cooling which may not be such a bad thing as it may allow the print to get cooled for longer as the print moves across the work piece.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

Re: Playing with the air nozzle design

It looks like the R4 nozzle positioning has changed, so I don't think this can be easily adapted. I figured I would attempt to cut the new mount off the stock shroud STL and stick it on this design, but saw that the R4 is much shallower and the fan opening is now in a different location as a result of the redesign. 🙁

RE: Playing with the air nozzle design

@georg-s2

Hi, metacollins settings keep failing for me also on the MK3S, gaps in perimeter walls and extrusion problems no matter how much a tweak the extrusion multiplier. i can't seem to find the location of your config file for polycarbonate? Can you help me out please?