New MK3 Layer shifting, uneven bed, and loud rattling noise coming from base

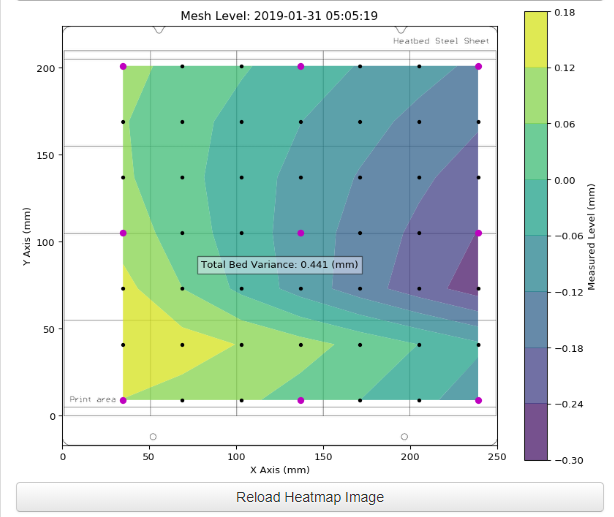

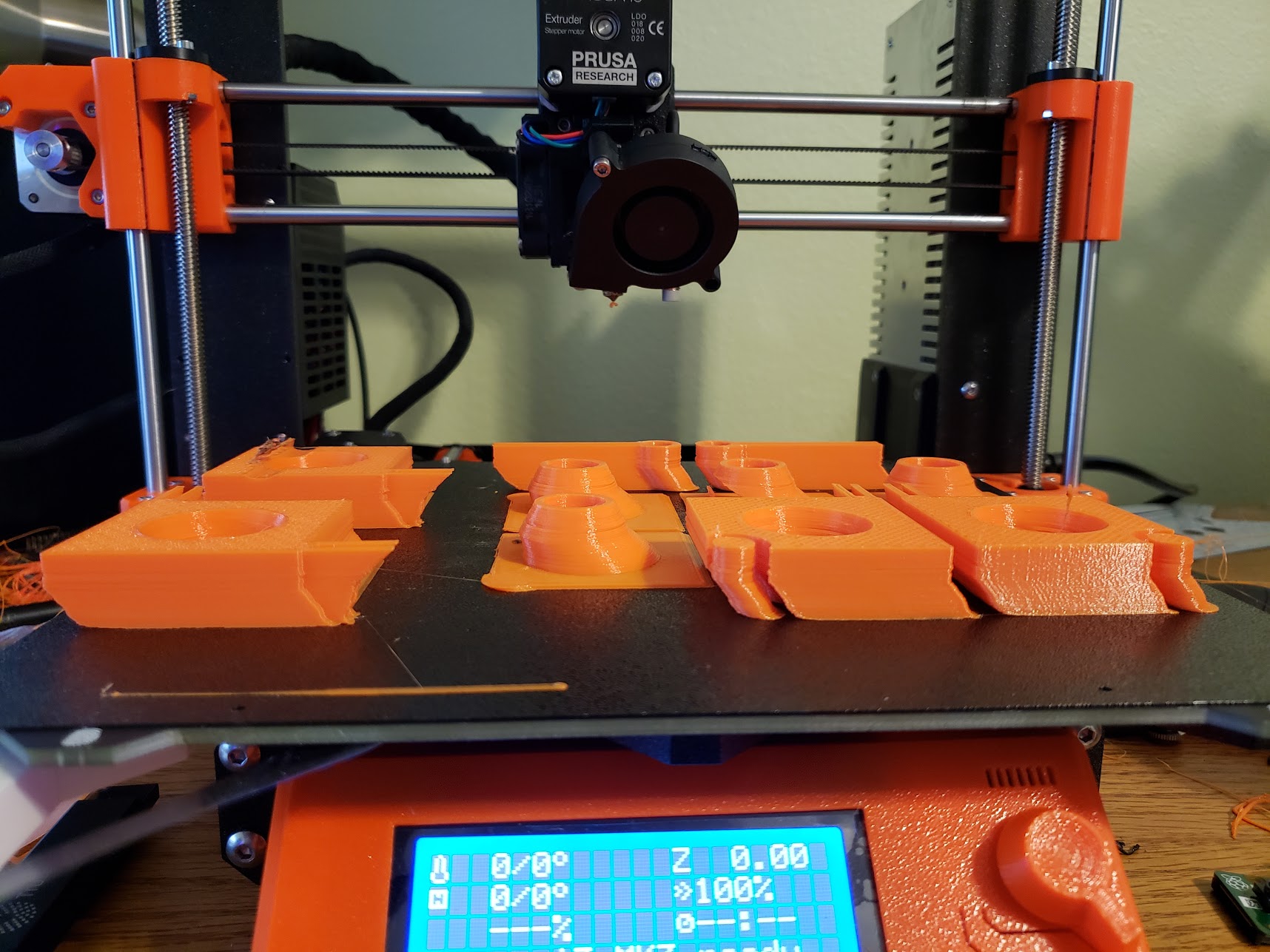

I just purchased and built the MK3 about 2 weeks ago and have had many successful prints. As of a few days ago, after an overnight spiralized print failed, I've been having layer shifting on every print. I readjusted the pinda with the ziptie, tightened all belts & screws, cleaned the bed, and recalibrated many times, but I still have an uneven bed. Layers shifting is in the -X direction and I can't find where the rattling is coming from. The rattling is loudest at certain speeds in any direction when it resonates likes bearings are vibrating. Regardless of the motor movement, the sound comes from the same place as far as I can tell, which is under the bed. Belts are tight and the U clamps holding the cylindrical bearings are tight. The pulley screws are tight too. I'm attempting to print Ikea Lack enclosure parts in orange and I'm close to running out from all the failed prints, so I decided to post. Does anyone have any ideas? Also, now my first layer adjustment height is -1.8mm, whereas before it was -0.8mm. I'm printing with orange PETG at 240C & 90C and whether I use original MK3 PEI or third party powder-coated PEI makes no difference.

Re: New MK3 Layer shifting, uneven bed, and loud rattling noise coming from base

printing from sdcard?

try using stealth mode or turning off crash detection.

your bed is fine, you probably don't need 90c to print petg though.

Re: New MK3 Layer shifting, uneven bed, and loud rattling noise coming from base

After hours tinkering and talking to support on live chat, I discovered several issues that caused the symptoms above: X-axis belt pulley tension screws were not tight and the pulley was flush to the tip of the mount bar. My U-bars were also way too tight, so I corrected them according to instructions, finger tight and then 1/4 turn. I believe I disfigured one of them, which doesn't slide as freely as the others, because I still have occasional layer shifts along the Y-axis. My X-axis belt was too tight as well as the back cover of the X bearings. I still struggle to find the right first layer height, which I have to adjust frequently.

I can't figure out how to get my Y-belt tension below 283 either. Any ideas, or is this ok?

Re: New MK3 Layer shifting, uneven bed, and loud rattling noise coming from base

Concerning the belt tension I'd like to repeat what I wrote already in another post:

The belt status values seem to be more of a guide than an exact instrument... plus in my opinion very misleading as guy.k2 explained already.

I had a similar problem with my prints actually getting worse with higher belt tension (because I wanted them to get close to that 240 status value, too). Searched the web and found a good guide on youtube to calibrate the tension via the sound frequency (like a guitar string):

He is using a free tool that might not have the prettiest interface, but you can actually watch the frequency change as you tighten the belt and pluck it repeatedly. Only works if you have some kind of movable microphone of course.

For my Prusa Mk3 I ended up with X-Axis: 86Hz and Y-Axis: 76Hz (higher tone, because the belt is bit shorter).

Then after performing a selftest the printer showed the belt status values of X-Axis: 287 and Y-Axis: 295. So according to the official manual I'm outside the recommended range, but my prints are better and both axes move much more smoothly.

Hope that helps!

Can confirm, that it's an easy mistake to not tighten the pulley tension screws and the extruder gear grub screw enough! That has been my problem for weeks as I thought, I did a good job assembling the printer, but after all I didn't ^^

Be careful with the extruder gear grub screw though... it is so small that poorly manufactured tools might wear it out quickly and then you'll have a hard time getting it out again. Plus you can't order them seperately in the Prusa shop. I already asked.