Melted cable at Einsy end

I was halfway through a print today, trying some new filament, and got a "BED THERMAL RUNAWAY" error. I opened up the CPU box to check the connections on the Einsy, and the positive connector's wiring hardness has melted. The metal connection on the end has been apparently so hot for long enough that the metal has corroded into nothing.

What in the WORLD happened here? Is this a typical problem with this board? The connections were snug and I was getting power. But now I'm afraid that this board is not managing voltage properly at all.

Has anyone else had this issue? Am I just cursed to NEVER having a working Prusa machine?

Re: Melted cable at Einsy end

Probably just a bad joint on either the connector on the end of the wire or the pin/terminal on the board itself. Just because connections look good from the outside doesnt mean they are making a solid connection inside.

A bad connection would raise resistance, and thus increase heat, to the point things could start melting.

Re: Melted cable at Einsy end

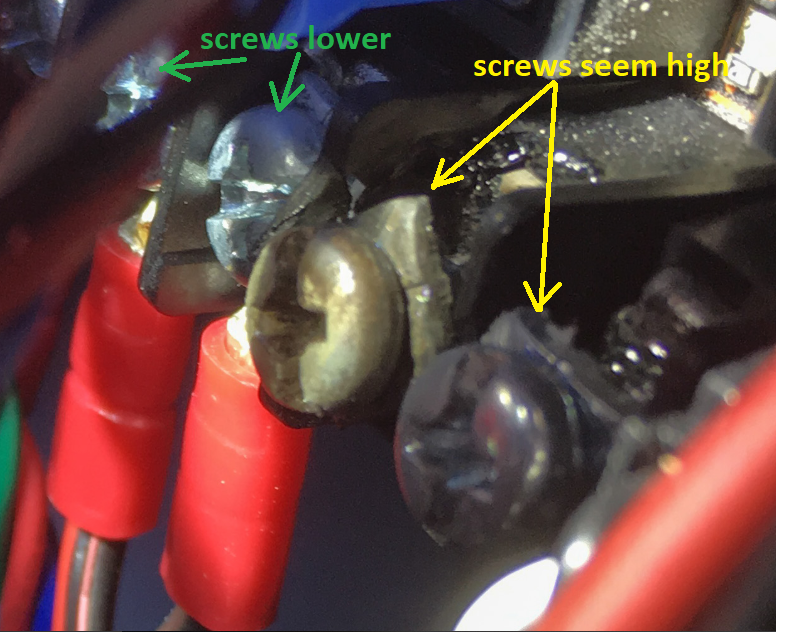

Here you can see the melting at the board connector for the heated bed's positive end:

Bubbling plastic on the connector and all. The plastic housing on the Einsy Rambo board is melted as well. Not super comfortable turning this thing back on even if I replace the connector on the end.

Re: Melted cable at Einsy end

I have this exact same issue.

How should we proceed in fixing it and/or preventing this kind of thing in the future?

Re: Melted cable at Einsy end

I would not turn that back on without replacing the mainboard and the cables.

Re: Melted cable at Einsy end

Seems odd that it would be the exact same cable on each with the same issue. Bad Einsy batch? Is anyone else having this issue on the mk3?

Re: Melted cable at Einsy end

That is very much an indication of a loose terminal and/or corrosion, ie the terminal screw was loose/corroded. The heat appears to radiate from the terminal forks. If the power terminal strip is not melted the board is probably fine. Pull the board out and check all solder connections to the terminal strip for heat damage. Clean the terminals on the terminal strip completely and replace power wire and a new fork terminal and screw.

Dan

Re: Melted cable at Einsy end

Also, the "green" on the terminal and conductor is an indication of high humidity or chlorine gas contamination..

Dan

Re: Melted cable at Einsy end

Also, the "green" on the terminal and conductor is an indication of high humidity or chlorine gas contamination..

Dan

That would be tricky to only affect one wire connection, though, given that they're all lined up next to each other. Humidity in the room is an even 45% (kept that way). And there's no chlorine in the house (no bleach here).

Re: Melted cable at Einsy end

Perhaps the other cables weren't effected because it was the motion of the heat bed that jostled these cables loose? They were sheathed with plenty of slack, though. Regardless I find it hard to believe that loose cables could result in such catastrophic failure. Doesn't a possible QC issue seem more plausible? [I placed my order 1/06/18, shipped 3/26/18]

The why matters to me because this whole ordeal has pretty much killed my confidence in running unattended or overnight prints. I splurged on a MK3 because I didn't want to burn my dorm down. If it's a QC issue, great, I'll get new parts. If this is an expected outcome from neglecting frequent maintenance, people should really be informed of it.

Re: Melted cable at Einsy end

Actually, according to Wikipedia, green copper corrosion can be chloride, sulfate, sulfide, or carbonate.

If the insulation on the wire is PVC plastic (a very common insulator), it contains chloride which will be released if the plastic is overheated to the point where it chemically degrades, so I think that's the most likely source.

The heat seems to be localized around the spade fork connector. If the screw on the terminal strip was tightened properly, then the likely culprit is improper crimping of the connector. There can be various causes for that, like insufficient clamping pressure during the crimping process, or the wire wasn't inserted all the way into the ferrule (sleeve) before crimping, or the insulation wasn't completely stripped.

This is a serious quality control issue, but it is not a design issue. The design is sound, if implemented correctly.

If the board was not overheated, the board should be OK to continue using. But you need to remove the board so you can inspect the underside for any signs of browning or overheating. If the board is not pristine, then I'd say to replace it.

Re: Melted cable at Einsy end

it's difficult to see from the picture, but it looks, to me, as if the connector fork was not fully seated...

this could be the cause of poor contact, or it could be the result of the overheating.

if something stopped the connector seating properly in the terminal block, overheating could easily occur

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Melted cable at Einsy end

I am 100% sure this cable was connected well before I unscrewed everything (which required breaking some plastic because it had all melted together).

N.

Re: Melted cable at Einsy end

it's difficult to do post mortem by photo...

best wishes for your repairs,

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Melted cable at Einsy end

it's difficult to do post mortem by photo...

best wishes for your repairs,

Joan

Thanks, Joan. It's easy enough to crimp on a new y connector (I have some in a box here). I'm just worried that the same thing will happen. I shall keep an eye on things and see if it's an issue with the connection itself or if the connector arrived in bad shape and I didn't notice.

It does make me wary of being able to print anything that takes a long time, though. I bought a Prusa because it was supposed to be rock solid. And now I'm worried to use it.

I will likely invest in another variety of 3D printers, as I NEED something solid to get my production done.

Re: Melted cable at Einsy end

Hi Neil,

that could get very expensive, and there is no guarantee that other printers will be any more reliable than your Prusa.

Tom Sanladerer tested a number of hobbyist printers and showed that the prusa mk3 was one of, if not, the best on a safety front.

You could pay a fortune for a commercial printer and it could also go faulty and cause a fire in the process...

there are a number of ways to mitigate issues, which may be more costeffective...

my local hack space, have created a metal enclosure, to contain the printer (it's not a Prusa i3). something like that (maybe non flamable material, for insulation purposes, with a fire / smoke sensor inside may be suitable for you.

If it were my printer, I would see if I could replace the connector strip, on the einsy board, and replace the cable / connectors as appropriate, re assemble and keep a watch on the situation.... till I was confident that the issue was fixed...

if the einsy is not repaireable I would get a replacement! and I would be very careful during reassembly to ensure all connections are tight and properly seated.

Your printer, your choice...

a smoke detector might also help keep your mind at rest.

in my previous house (3 story) I fitted mains powered interlinked smoke detectors, so that if for example a fire started in the basement, all alarms would sound on the other floors. never used it in anger, but when we got a blow back from the solid fuel fire in the basement, every body in the house knew about it!

in business premises you often have fire alarms, perhaps add a node, near the printer

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Melted cable at Einsy end

it's difficult to do post mortem by photo...

best wishes for your repairs,

Joan

Thanks, Joan. It's easy enough to crimp on a new y connector (I have some in a box here). I'm just worried that the same thing will happen. I shall keep an eye on things and see if it's an issue with the connection itself or if the connector arrived in bad shape and I didn't notice.

It does make me wary of being able to print anything that takes a long time, though. I bought a Prusa because it was supposed to be rock solid. And now I'm worried to use it.

I will likely invest in another variety of 3D printers, as I NEED something solid to get my production done.

Honestly if you are not going to replace the board i would not use another connector, i would solder the wire directly to the board.

That way it will have a more solid connection and even if it does overheat again it wont melt as much as the solder will melt and the wire will just fall off breaking the connection before it does much damage,

Re: Melted cable at Einsy end

As I said before, this particular case of overheating is NOT a design issue. It's NOT a problem with all Prusa printers. There was some bad workmanship somewhere along the way. By the way, if it was a design issue, you would see more than one wire overheating. It's a rule of electrical circuits that "what goes out must come back" - meaning that the current going to the bed heater on one wire comes back on an adjacent wire; they carry exactly the same current, just in opposite directions. So if it were a design problem, TWO wires would be overheated, not just one. This PROVES it's a case of faulty assembly. If you can fix the assembly correctly, it won't overheat.

I'm an electronics engineer and before I retired I worked in a manufacturing industry that uses thousands of refrigerator-size control cabinets with hundreds or thousands of connections in every cabinet. Not all of the connections carry high power, but many do. So how does a billion-dollar manufacturing company deal with the potential problem of poorly-crimped connectors or screw terminals that might not be tightly fixed in place? Once a year, the open up the cabinet door and use an IR camera to take a picture of the whole thing. If there are any hot spots, they will show up quickly.

In the case of the Prusa, only the screw-terminal connectors on one edge of the Einsy board carry high current and could be subject to overheating like what you saw. So if you have an IR camera, open up the door and take a look at the screw terminals after you've run the printer for an hour or so. If everything is near room temperature, then you don't have a problem. If you don't have an IR camera, touch the terminals with your fingers (24 volts is not going to hurt you).

As Joan said, any equipment, no matter how much it costs, can have defective workmanship somewhere inside. And it's prudent for all 3D printer users to take as many precautions as possible to avoid hazardous situations, particularly when the equipment is new. Have smoke detectors, have a fire extinguisher nearby, and inspect frequently. Once you have experienced enough trouble-free operating time you can cut back on the inspections and/or start running the printer unattended for longer periods - but only you can make the judgement about how much inspection and experience is "enough".

Re: Melted cable at Einsy end

I crimped on a good connector, cleaned the connector terminal, and put it back in service. I'll keep an eye on it for a week or so and see how it's going before I leave it unattended, though. If it does this again, I'm definitely going to chalk this up to faulty board and not faulty wiring. I wire things up for a living, so I know damned well it's not MY wiring job. 🙂

Re: Melted cable at Einsy end

Hi, I had this same problem happen to me with my MK3 i3 (see picture attached).

You can see here that terminal screw for the red wire coming from the heated bed is burnt along with the red jacket beneath. You can also see from the picture that this screw is slightly raised more than the others.

Immediately after starting the print, I saw a spark emit from the encasement then about 3 seconds later smoke began and I smelled the burning. This is after weeks of flawless printing while hearing a "clicking" sound coming from the motherboard that happened at the same frequency as the LED on the heated bed. I wonder if these are related issues. I did some research on this topic and it seems to be harmless.

Lesson learned about tightening down all terminal screws. I will follow Neil's steps and see if the problem occurs again. I do not think I will need a new motherboard but will inspect that connector terminal to be sure. Thanks for the discussion.