Loose Heater Block after changing nozzles

Hi Folks, I am not sure if this is normal so I want to address it to the pros to get it clear. When I change my nozzle and retighten it to the heater block, the block is moving easily on his axis - in other words, it´s not tight. Is this normal, that you could turn the block?

If not, what can I do to fix it?

Thanks for your help.

Cheers. Christian

RE: Loose Heater Block after changing nozzles

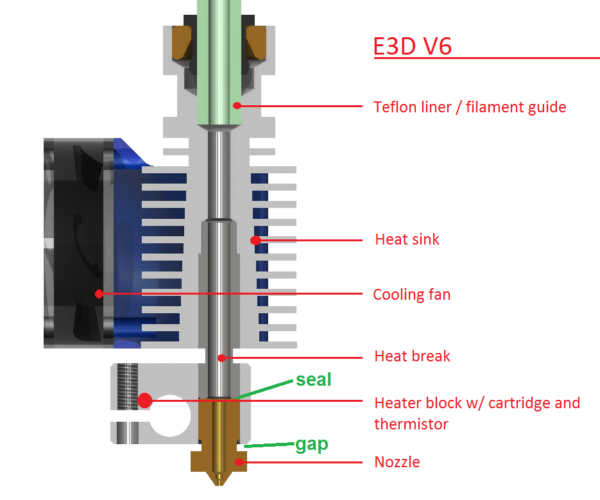

Be careful: The nozzle should to tightened up against the heatbreak at 285C. The heater block acts as a nut between them. There should be a small <1mm gap between the nozzle hex and heater block. It should not be tightened flush against the block. When done properly, there should be no wiggle between the nozzle, heater block and heatbreak assembly.

The overlap in terminology is confusing.

RE: Loose Heater Block after changing nozzles

Hi Folks, I am not sure if this is normal so I want to address it to the pros to get it clear. When I change my nozzle and retighten it to the heater block, the block is moving easily on his axis - in other words, it´s not tight. Is this normal, that you could turn the block?

If not, what can I do to fix it?

Thanks for your help.

Cheers. Christian

A small schematic representation to help:

or this short video:

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Loose Heater Block after changing nozzles

dont ever change nozzles, ever !

the headaches that follows involves rebuilding the extruder, complete tear down, its not worth it.

The sad thing is the heatbreak is not secured to anything else, it loosely screws into the cooling fins, therefore this means when you try to tighten your nozzle, the heatbreak rotates with it, once the heatbreak has screwed itself inside the fins, the nozzle now tightens against the heater, which is wrong. I think there are other extruders on the market that overcome this headache.

just dont do it, I did it once, never again !

RE: Loose Heater Block after changing nozzles

@gavin-b5

"dont ever change nozzles, ever !" If ever YMMV was true it is here. I was just about to post that I'd finally decided to do something about my sporadically clogging nozzle and having changed to a new nozzle it's like a new machine. C'est la vie.

Also in essence the Prusa heatbreak/block/nozzle is a E3d v6, a widely respected (and cloned) design.

RE: Loose Heater Block after changing nozzles

@bobstro

Thanks Bobstro, did always change my nozzle like described in the manual. It seems I have to do a complete rebuild of the hotend as Gavin stated. I am not sure, but I remember that this issue was also there when I got the kit. As I was new to this business I thought it´s was not faulty. Anyways, I´ll try to rebuild the whole thing - or is it possible to unscrew the heater block and fix the heatbreak without doing a complete disassemble?

RE: Loose Heater Block after changing nozzles

@gavin-b5

Hi Gavin, thanks for your feedback but I have to change the nozzle from time to time. Printing a lot with 0.6 and some parts with more quality on 0.4. Otherwise, I agree: Never touch a running printer 🙂

RE: Loose Heater Block after changing nozzles

[...] The sad thing is the heatbreak is not secured to anything else, it loosely screws into the cooling fins, therefore this means when you try to tighten your nozzle, the heatbreak rotates with it, once the heatbreak has screwed itself inside the fins, the nozzle now tightens against the heater, which is wrong.

If the heatbreak is turning, you're doing it wrong. Brace the heater block with a 16mm open wrench and nothing but the nozzle should be able to turn.

I swap nozzles daily with no issues. Like everything else, practice helps, but there's no reason to fear a nozzle swap if you want to get the most out of your printer.

RE: Loose Heater Block after changing nozzles

dont ever change nozzles, ever !

the headaches that follows involves rebuilding the extruder, complete tear down, its not worth it.

The sad thing is the heatbreak is not secured to anything else, it loosely screws into the cooling fins, therefore this means when you try to tighten your nozzle, the heatbreak rotates with it, once the heatbreak has screwed itself inside the fins, the nozzle now tightens against the heater, which is wrong. I think there are other extruders on the market that overcome this headache.

just dont do it, I did it once, never again !

Whilst everyone is entitled to their own opinion; this would have to rate as some of the worst advice going around. One bad experience does not justify sweeping advice like that.

I change between a 0.4 and 0.25 nozzle up to 3 times a day some days.

It's quick and easy to do. A little practice and care and it's all over in minutes with no fuss.

Rebuilding your hot end isn't that bad either. If I had my time again, and I probably will in the near future as I intend to get another MK3S; I would strip and rebuild the hot end before assembling the printer to make 110% sure it's been assembled correctly.

I ended up having to do it 2 weeks after getting my printer because I found out the hard way that it had been poorly assembled from the factory.

This is an excellent video on the correct way to build the E3D V6 hot end:

RE: Loose Heater Block after changing nozzles

@bobstro

- The heatbreak does not tighten against anything except the nozzle

- If the nozzle is removed the heatbreak can rotate in any direction, if you screw the heatbreak further in, it will keep screwing further and will not tighten against anything, if you keep screwing it in, it will eventually come out the top of the heatsink( I verified this with mine after I had disassembled it)

- The heat break should have high quality thermal paste on it to conduct heat to fins, if this dries out it could stop the heatbreak from turning, but eventually it will come loose and then screw further in.

- The clearance gap between heater and nozzle is specified, if the heatbreak screws in, you cannot unscrew it, there is no access to it.(check the picture above to confirm this)

- When the nozzle starts tightening up against the heatbreak, there is nothing to stop the heatbreak rotating further in as you tighten the nozsle, holding the heater with a spanner does not stop the heater break from turning.

- The ugly bit: once the heatbreak screws in 1mm or 2mm, there is no way to screw it back out again and your nozzle / heater clearance is gone, the only way to do this to strip down the entire extruder with a lot of other parts. I am really good with mechanical stuff and it took me the whole morning.

RE: Loose Heater Block after changing nozzles

@bobstro

- The heatbreak does not tighten against anything except the nozzle

Per E3D's guide, it should be hand tightened into the heatsink.

- If the nozzle is removed the heatbreak can rotate in any direction, if you screw the heatbreak further in, it will keep screwing further and will not tighten against anything, if you keep screwing it in, it will eventually come out the top of the heatsink( I verified this with mine after I had disassembled it)

If the nozzle is loose, that is true. Once assembled per E3D's guide, the nozzle should not be lo0se. Are you able to rotate the nozzle and heartbreak when tightened with the heater block braced per E3D's guide?

- The heat break should have high quality thermal paste on it to conduct heat to fins, if this dries out it could stop the heatbreak from turning, but eventually it will come loose and then screw further in.

That is true, as is the fact that the heatbreak will rotate without any thermal paste applied to the heatbreak. Everything can be rotated when partially disassembled, unsurprisingly. In a properly assembled E3D V6 hotend, this would also require the heater block to be rotated. This should not happen if the block is braced per E3D's guide.

- The clearance gap between heater and nozzle is specified, if the heatbreak screws in, you cannot unscrew it, there is no access to it.(check the picture above to confirm this)

You are correct that there is no ready access to it. Under normal circumstances, this is not an issue on a properly assembled E3D V6 hotend.

- When the nozzle starts tightening up against the heatbreak, there is nothing to stop the heatbreak rotating further in as you tighten the nozsle, holding the heater with a spanner does not stop the heater break from turning.

When the nozzle butts up against the heatbreak inside the heater block, it stops rotating. If too much force is applied, the heater block can easily strip. If you are able to rotate the heatbreak with the nozzle while bracing the heater block per E3D's guide, please advise E3D.

- The ugly bit: once the heatbreak screws in 1mm or 2mm, there is no way to screw it back out again and your nozzle / heater clearance is gone, the only way to do this to strip down the entire extruder with a lot of other parts. I am really good with mechanical stuff and it took me the whole morning.

The block can rotate if not braced, so it's entirely possible that it can happen. It should not happen during a normal nozzle replacement if bracing the block per E3D's guide. Or to more fully address your dire warning against ever-changing a nozzle, "if your block and/or heatbreak are turning, it is likely happening due to some other cause than changing the nozzle if you are changing the nozzle per E3D's guide. I'm not suggesting that the block/heatbreak can't rotate. Mine has done so. But if I take care to brace the heatbreak per E3D's guide when changing nozzles, it doesn't happen across dozens of nozzle changes. The original Prusa guide suggested rotating the block 1/4 turn, and that procedure is not recommended (although it should work if rotated back per their guide.

In addition to the heatbreak rotating, you neglected to mention that the entire hotend can be rotated or misaligned. If someone is careless, there are a number of related problems that can occur. I am simply emphasizing that the nozzle replacement procedure should not be the cause of such problems if done per E3D's guide.

If you would like to take issue with E3D's guide, I can only suggest that you contact them directly or enter comments into the guide using the field provided. I and many other users do not find routine nozzle replacement to be a cause of failures. Limiting one's use of an expensive printer based on FUD is not necessary. User's need to know how to properly replace nozzles as they are ultimately consumables and can be expected to require replacement during routine operation of the printer.

RE: Loose Heater Block after changing nozzles

I purchased a "ZCatch 3D printer nozzle removal tool" in the hope that it would prevent such problems. But I have still not changed my nozzle. Can these special nozzle removal tools help with this issue?

RE: Loose Heater Block after changing nozzles

I purchased a "ZCatch 3D printer nozzle removal tool" in the hope that it would prevent such problems. But I have still not changed my nozzle. Can these special nozzle removal tools help with this issue?

They can help, but fully reading through the E3D guide and developing an understanding of what's going on should keep you out of trouble. I see a lot of people emphasizing the 1mm gap between nozzle hex and block, but with no mention that it should be impossible to tighten the nozzle up against the block if you've done it correctly. Instead, "1mm gap" becomes a magical incantation, and ensuring the heartbreak is properly positioned -- the real issue -- is barely mentioned.

Good tools help. The better you can see, the easier it is to work on the assembly. I like a simple 16mm open wrench/spanner and 7mm socket. The socket keeps hot nozzles from bouncing around into awkward places.

The E3D hotend is not perfect by any means. I do like the newer mosquito and dragon variants partly because they do have a more robust nozzle mounting approach. I just don't want Mk3 users to think that changing nozzles is a big scary operation that will harm their printer or cause endless problems. Like everything else in 3D printing, there's a technique you need to use, but it's straightforward.

RE: Loose Heater Block after changing nozzles

@gibell

Where did you buy the "ZCatch 3D printer nozzle removal tool"?

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Loose Heater Block after changing nozzles

@karl-herbert

I bought it from amazon.com.

RE: Loose Heater Block after changing nozzles

@gibell

Thanks!

would you publish the link to the tool?

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Loose Heater Block after changing nozzles

@karl-herbert

RE: Loose Heater Block after changing nozzles

@gibell

Thanks! I know the tool from a kickstarter campaign ( https://www.kickstarter.com/projects/413791439/nozzle-removal-tool-for-fdm-3d-printers ) in 2018. No longer available at Amazon but here: http://www.3dprinthings.be/shoppingcart/?shippingCountry=14

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Loose Heater Block after changing nozzles

"When the nozzle butts up against the heatbreak inside the heater block, it stops rotating. "

NO it does not stop rotating, you are simply lucky if it does not rotate. There is nothing from stopping the heatbreak from turning further in, when the nozzle butts up against the heatbreak as it turns in, it could start turning the heatbreak as it rotates and butts up against it whilst tightening. If your heatbreak has remained static then you are simply lucky, there is no engineering reason why the heatbreak should remain static, the heatbreak has not tightened up against anything nor is there anything holding it in place before you start tightening the nozzle against the heatbreak.

Its like having a extra long nut with two bolts either end screwing into the nut and when you tighten the bolt up against the other bolt your are expecting the other bolt to stay static while you tighten up against, there is nothing from stopping the other bolt from rotating and screwing out as two forces, one of rotation and one of direct force are applied to it. Ideally there should be a grub screw or something holding the heatbreak in place so it cannot rotate.

RE: Loose Heater Block after changing nozzles

I think whoever has ever disassembled and reassembled a V8 big block can also change nozzles. Otherwise I would start with that 🙄 ...

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.