how do I start printing without bed leveling?

Hi,

how do I start printing without bed leveling please? Without G29 it does home everything but it starts printing too high. Is there any way to tell the printer to perform bed leveling only in home position?

thanks

Re: how do I start printing without bed leveling?

Take the mesh bed levelling com.and out of Gcode. Just use home all axis.

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: how do I start printing without bed leveling?

Tried that but it does not take the Z correction into account. Printing starts too high.

Is there any command to load the Z calibation value out of eprom?

Re: how do I start printing without bed leveling?

sorry, no idea

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: how do I start printing without bed leveling?

But you know what I mean, right?

The Z homing is one thing. The offset is set during First layer calibration and this offset is not set when starting print without G29

I want to be sure that it’s clear what I want to achieve

Re: how do I start printing without bed leveling?

odd, I have just commented out the mesh bed levelling, and my printer has just started the print with home all, and progressed the print with Live z -100

WITHOUT MESH BED LEVELLING!

???

Please try the file!

JoanI

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: how do I start printing without bed leveling?

yeah that's odd. Mine starts printing in mid-air, have look at the attachment, started printing your file and stopped it after the layers were not sticking at all

firmware 3.3.1, could not upgrade to 3.5.0 as it was too buggy imho. Can somebody confirm whether my issue is fixed in later releases or is it something I have wrong?

putting G1 Z-0.8 F500 would be a solution for me maybe. If you are asking why would one disable mesh bed leveling. Answer: PINDA sensor is not accurate enough to detect differences in such a small range (Official Prusa Support answer). The always-different measurement results only proves it. Mesh leveling is therefore no use for me. It only slows down the start of the print and causes the filament to leak out of the nozzle while not printing and performing that funny procedure

Re: how do I start printing without bed leveling?

Can you please explain what you are attempting to achieve by printing without the G29?

In theory this is possible, but unlike standard Marlin the Z offset isn’t stored as a Z offset M851, it’s an internal “babystep z” value used to offset the Z axis position.

It’s just standard practice on an MK3 to do a G29 before printing to enforce that...

I’d call it a safety issue preventing crashing on files sliced for other printers.

Re: how do I start printing without bed leveling?

Yeah sure: to speed up printing.

I’ll quote myself: PINDA sensor is not accurate enough to detect differences in such a small range I need it to be (Official Prusa Support answer). The always-different measurement results only proves it. Mesh leveling is therefore no use for me. It only slows down the start of the print and causes the filament to leak out of the nozzle while not printing and performing that funny procedure

Re: how do I start printing without bed leveling?

Yeah sure: to speed up printing.

I’ll quote myself: PINDA sensor is not accurate enough to detect differences in such a small range I need it to be (Official Prusa Support answer). The always-different measurement results only proves it. Mesh leveling is therefore no use for me. It only slows down the start of the print and causes the filament to leak out of the nozzle while not printing and performing that funny procedure

You can move your filament sensor down a half mm and re-calibrate your live-z if you're really concerned about the nozzle "kissing" the bed.

As far as the PINDA being repeatable, it's basically the best system in the industry, and the Prusa has no faculties for mechanical bed leveling, it's part of the platform.

I would advise you to track down the root of your issue rather than go straight into modifying the machine's intended behavior.

Re: how do I start printing without bed leveling?

induction sensors don't have the accuracy needed in this industry, simple as that.

all of my 9 mesh leveling points are pretty much the same level. but I am experiencing bumps between calibration points. Slight but they are there, it's quite noticeable when printing 0.1mm first layer. I already have my heated bed and steel plate replaced. Better but not perfect at all.

That's why I want to turn off the mesh bed leveling just like how I disabled that filament sensor. That sensor only triggers pauses and failures during the print because the filament is "too shiny" (Support said also to other people on the forum) and it's beyond laser sensor's capabilities to detect the presence. I would rather have a printer which I can print on without turning the sensor off/on after changing filament and deciding it's "shiny enough" for it. Or not having to remove leaked residues on the calibration points.

Same with the bed leveling. It's no use for me, filament (especially PETG) is leaking when the nozzle is heated up, leaves pieces of leaked filament on the printing bed so I need to remove them during mesh leveling.

I simply don't have the nerves to spend weeks with Support to get the answer that this is a physics and it is normal (just like the PINDA inaccuracy being in tolerance and laser sensor triggering false alarms because of "too shiny" filament). I bought the MK3 which now I see as my top mistake of 2018 and I have to live with it. But I need to remove few impediments to make the printing less annoying for me.

Not bitching, just explaining why I am turning off feature by feature. They are useless to me, they are slowing me down and based on my experience with Support (or this forum) I don't want to solve them anymore, I gave up already.

so there is nothing available to print without bed mesh leveling while having the Z calibration offset applied? Is the G1 Z-0.8 F500 (considering my offset is -0.8) instead of mesh bed leveling the only way?

Re: how do I start printing without bed leveling?

induction sensors don't have the accuracy needed in this industry, simple as that.

all of my 9 mesh leveling points are pretty much the same level. but I am experiencing bumps between calibration points. Slight but they are there, it's quite noticeable when printing 0.1mm first layer. I already have my heated bed and steel plate replaced. Better but not perfect at all.

Explain or show pictures of the “bumps” you describe.

If you’re just referring to a rough top surface of your first layer as “bumps”, it could just be that tour Live-Z is simply a bit too low...you ideally want a smooth top surface on your first layer.

Re: how do I start printing without bed leveling?

No, I don't refer to wrong Z offset. I'm refering to non-flat printing surface. Well, it's flat, plus minus 0.04mm on few spots. Smooth first layer is exactly I would like to achieve. but read this:

these photos are from before Support finally decided to replace my bed and steel sheet. now it is better but still not 100%. Posting it here only to explain what "bumps" in my english mean.

I did the 1st layer calibration properly and then I re-ran it without touching the knob (the offset was the same during whole process), I let it finish and took the photos to show inconsistent 1st layer height on the steel sheet. Note that mesh bed leveling has been done as part of the 1st layer calibration and there is a difference in the layer thickness (and also width). Before it was 0.7mm, after heated bed and steel sheet was replaced, the maximum is 0.04mm. I can live with that by setting first layer width to be at least 0.15mm.

As a result in an extreme situation, if I'm gonna print 1st layer at 0.05mm height, it will be 0.05mm on places where the mesh bed leveling points are. But between them the layer will be thicker (and the lines will not be touching each other), or the nozzle would scratch my steel sheet. The layer thickness is correct in the center, and corners. but it's not correct between some of those mesh bed leveling points. Nobody really does print the 1st layer at 0.05mm of course

I really don't want to solve this problem, here nor anywhere else. I already gave up after the experience with Prusa Support team, which told me the PINDA probe is not accurate enough to detect such a small difference as one of results of the "investigation". They are most appropriate experts for me, but unable to provide a solution, how can I - normal user - track it down and resolve myself? My printer has 0.0 degrees skew, is perfectly perpendicular and yet I don't have perfectly flat surface. And there's nothing I can do with it

Therefore I consider mesh bed leveling completely useless for me, I'd rather say annoying, to be started before every print. I did not buy MK3 to have something to go regularly check for false alarms on filament sensor, or stepping in front of the printer with tweezers and removing leaked filament from the nozzle or printing surface during the mesh bed leveling. I want a reliable printer which starts printing quickly, does not scream every 15 minutes that it ran out of filament (BLACK PETG, no transparency). Removing mesh bed leveling brings me closer to that.

My statements are my personal views and are not supposed to offend anyone.

Re: how do I start printing without bed leveling?

No, I don't refer to wrong Z offset. I'm refering to non-flat printing surface. Well, it's flat, plus minus 0.04mm on few spots. Smooth first layer is exactly I would like to achieve. but read this:

I did the 1st layer calibration properly and then I re-ran it without touching the knob (the offset was the same during whole process), I let it finish and took the photos to show inconsistent 1st layer height on the steel sheet. Note that mesh bed leveling has been done as part of the 1st layer calibration and there is a difference in the layer thickness (and also width). Before it was 0.7mm, after heated bed and steel sheet was replaced, the maximum is 0.04mm. I can live with that by setting first layer width to be at least 0.15mm.

Just a point of clarification, did you re-run calibrate Z or first layer cal with the new sheet? There are production tolerances on the sheet and when you switch sheets you need to properly compensate...

As a result in an extreme situation, if I'm gonna print 1st layer at 0.05mm height, it will be 0.05mm on places where the mesh bed leveling points are. But between them the layer will be thicker (and the lines will not be touching each other), or the nozzle would scratch my steel sheet. The layer thickness is correct in the center, and corners. but it's not correct between some of those mesh bed leveling points. Nobody really does print the 1st layer at 0.05mm of course

When you're doing a .05mm "ultra-detail print", it still prints first layer at .2mm.

I really don't want to solve this problem, here nor anywhere else. I already gave up after the experience with Prusa Support team, which told me the PINDA probe is not accurate enough to detect such a small difference as one of results of the "investigation". They are most appropriate experts for me, but unable to provide a solution, how can I - normal user - track it down and resolve myself? My printer has 0.0 degrees skew, is perfectly perpendicular and yet I don't have perfectly flat surface. And there's nothing I can do with it

Are both your sheets powder coated? The thickness variance on the powder coated specifically would be somewhat higher than the PEI sheet, I would imagine, just due to the nature of their construction...

Therefore I consider mesh bed leveling completely useless for me, I'd rather say annoying, to be started before every print. I did not buy MK3 to have something to go regularly check for false alarms on filament sensor, or stepping in front of the printer with tweezers and removing leaked filament from the nozzle or printing surface during the mesh bed leveling. I want a reliable printer which starts printing quickly, does not scream every 15 minutes that it ran out of filament (BLACK PETG, no transparency). Removing mesh bed leveling brings me closer to that.

You can disable the filament sensor if it doesn't work correctly with your filament, that seems to be a separate issue.

I did mention that if you want to reduce/eliminate the pre-print z-calibrate "kissing", you can adjust your PINDA down .5mm and re-run wizard to give yourself a little more headroom; there are also some folks who adjust the retraction and heating cycle pre-print g-code to keep the nozzle warm but not print-temp, which also mitigates ooze, but I like to keep folks running as "stock" as possible.

My statements are my personal views and are not supposed to offend anyone.

I hope some of that info helps, I'm sorry you were disappointed in the response from PR support, but your request is a bit outside the norm; you're printing fine but it's just not "good enough" for you.

I'm certain that together we can get this operating within acceptable tolerances for your needs, if you want to continue troubleshooting.

As a dumb thing, just for sanity check, run a Calibrate Z (only Z!) to make sure your X-Axis didn't get accidentally shifted, it happens, and the machine will compensate within a certain window, but there are artifacts with that compensation especially at low-layer heights; if you force a calibrate Z you eliminate that, and it's just too easy to miss as a *thing* that trips people up on an otherwise *perfect* machine.

Another silly thing, do you have some acetone you can clean off your sheet with? 100% Pure Acetone, not the blue stuff, two ingredients: acetone and denatonium benzoate, if it's got other stuff in there it's not going to properly rejuvenate the PEI surface.

And hey, if you need someone to "inspect" that extra powder coated sheet, let me know, I'm itching to get one. 🙂

Re: how do I start printing without bed leveling?

Just a point of clarification, did you re-run calibrate Z or first layer cal with the new sheet? There are production tolerances on the sheet and when you switch sheets you need to properly compensate...

When you're doing a .05mm "ultra-detail print", it still prints first layer at .2mm.

I mean printing really 0.05mm first layer. Slicer has to be adjusted to do that of course. No

Are both your sheets powder coated? The thickness variance on the powder coated specifically would be somewhat higher than the PEI sheet, I would imagine, just due to the nature of their construction...

I did calibration again completely, as I was replacing heated bed as well

You can disable the filament sensor if it doesn't work correctly with your filament, that seems to be a separate issue.

I did mention that if you want to reduce/eliminate the pre-print z-calibrate "kissing", you can adjust your PINDA down .5mm and re-run wizard to give yourself a little more headroom; there are also some folks who adjust the retraction and heating cycle pre-print g-code to keep the nozzle warm but not print-temp, which also mitigates ooze, but I like to keep folks running as "stock" as possible.

Tried that, but PETG is leaking quite a lot, if I don't cut it off with tweezers, it can produce few centimeters. So even few millimeters don't help, been there 🙁 that's the physics, it's nothing Prusa can fix. Filament sensor is disabled already since few destroyed prints

I hope some of that info helps, I'm sorry you were disappointed in the response from PR support, but your request is a bit outside the norm; you're printing fine but it's just not "good enough" for you.

I'm certain that together we can get this operating within acceptable tolerances for your needs, if you want to continue troubleshooting.

As a dumb thing, just for sanity check, run a Calibrate Z (only Z!) to make sure your X-Axis didn't get accidentally shifted, it happens, and the machine will compensate within a certain window, but there are artifacts with that compensation especially at low-layer heights; if you force a calibrate Z you eliminate that, and it's just too easy to miss as a *thing* that trips people up on an otherwise *perfect* machine.

Another silly thing, do you have some acetone you can clean off your sheet with? 100% Pure Acetone, not the blue stuff, two ingredients: acetone and denatonium benzoate, if it's got other stuff in there it's not going to properly rejuvenate the PEI surface.

And hey, if you need someone to "inspect" that extra powder coated sheet, let me know, I'm itching to get one. 🙂

just to be clear, I never contacted Prusa Support after I got my replacement, I don't have the nerves anymore. I'm trying to solve everything myself. And when I'm stuck, I ask on this forum and then I'm stuck on my own again.

I have returned that first powdered sheet and the heated bed already, Prusa Support has asked to return it for inspection, I would send it to you if I have it 😄 Acetone, calibrations, all done, I'm not a beginner. Did not help unfortunately 🙁

but thanks for the advices, I appreciate it 😄 maybe I'm really expecting something that MK3 cannot deliver. Including straight walls and perfectly aligned layers

Re: how do I start printing without bed leveling?

From what I can tell of your first layer cal result in the last pic you posted, there is something going on with your machine for sure.

So let's figure it out.

If you just freshly ran a cal, and you haven't touched the machine, re-run a first layer cal without adjustment and let's see the lines.

The "meander" line should have consistent width across the whole run.

If you've touched the machine at all, just run a Calibrate Z for everyone's sanity...yours especially.

That's the first thing I'm noticing, if you can't get first layer cal to look good, nothing is going to work...

Then we can dial back and get you to your Valhalla of .05 first layer, though I'd argue .2 first layer just to establish stick is probably a good practice anyway even if you're printing super low layer heights.

The only other thing I can guess is that maybe you're at the "fuzzy edge" of the PINDA's sensing ability, it might actually need to be closer to get good sensing.

There is a "debug" cal output we can try if we get that far, but for now, let's just establish your "status quo" with regards to first layer cal...

As far as the "ooze", as I mentioned, you can use some g-code tweaks if it really bugs you...I watch the first layer go down every time, so it's a non-issue for me, as I keep saying, let's just start with getting a consistent 1st layer cal and work up from there.

Re: how do I start printing without bed leveling?

okay, let's try to fix it 😄

I

'll perform the calibration first and post back here

Re: how do I start printing without bed leveling?

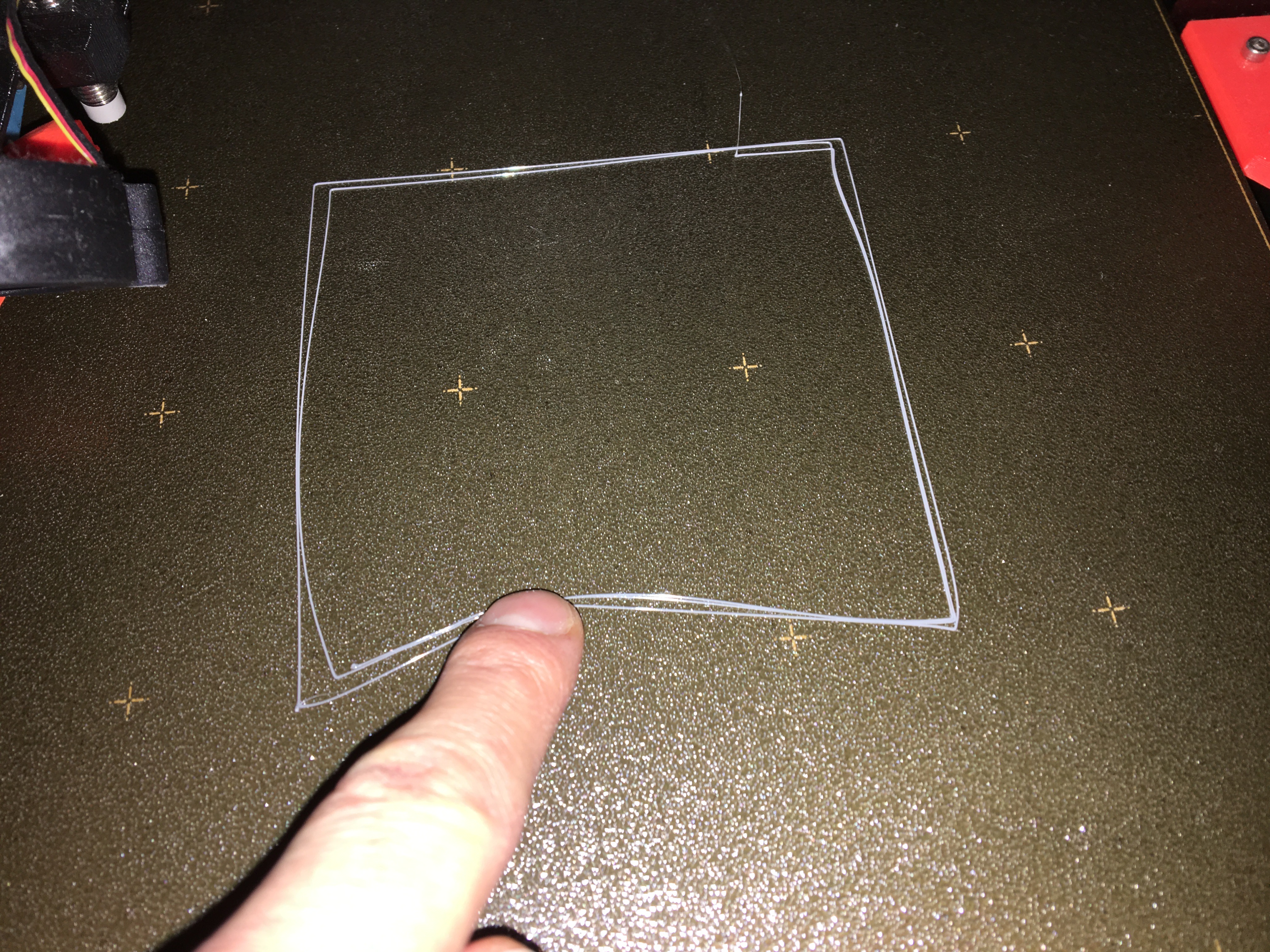

so here it is. I performed full XYZ calibration, measured skew is 0.01 degree. Z and first layer calibration with double sided PEI sheet (not powdered this time)

I have started a print with first layer set to 0.2mm, after it was almost finished, I stopped the print and took photos and measured the thickness. You can see quite a difference in the back left corner and front right one.

Note that the mesh bed leveling has been done before the print. I'm thinking about looking at the Y rods alignment. If these are okay, then putting something under the heated bed to make it higher.

what do you suggest? from the photos it's clear that back left corner of the bed is lower than the rest. It's Christmas today, so I won't be able to perform more tests in next few days, but I'd welcome a suggestion since I started messing with it again 🙂

thanks

Re: how do I start printing without bed leveling?

When I read what I wrote, I’m realising that the Y rods may be the culprits.

Quick measurement shows that the left rod’s back end is below the other rod ends. And it wiggles due to probably faulty rod holder. When I have time during Christmas I’ll print out new parts and replace the original ones. Could really help

Re: how do I start printing without bed leveling?

I asked for a "first layer cal" run to gauge the meander that goes all the way across the bed, but this is good enough for starters...

You know that scene in the 1st batman movie where michael keaton is talking to jack nicholson:

"You wanna get nuts? C'mon, let's get nuts!"

This is enough of a noticeable difference that it should be compensated by leveling, honestly it should.

You're clearly getting some kind of z-height offset left to right, so let's "not trust" the machine:

Do this, using the menus, run your Z close to the bed, close enough where you can see the nozzle's reflection in the surface of the PEI.

Shut off the machine, take extra caution not to touch the Z-rods as you manipulate things.

Glide the head left to right, watch the distance of the reflection compared to the nozzle (or not) across the surface.

To *manually* correct the X-Axis to make it planar to the nozzle, simple raise or lower one side by manually indexing the z-rod.

Once this is complete, and you're comfortable with the *x-axis fine adjustment* left to right with the nozzle planar to the bed, move the bed back and forth - as long as the machine is built correctly, there should be no change front to back...that would indicate a deeper mechanical issue.

With that process complete, turn on the machine, move the Z up a bit for safety (I like the long press from the menu for a quick Z raise), and run a print *without* touching anything, or better yet, just run a first layer cal and give me the pic to check the distances, or that print you ran, that's a good check too.

Performing a Calibrate Z will reset the X-Axis to "machine specs", your manually dialed in *trim* will stick as long as you don't re-calibrate Z.