RE: Filament Problem

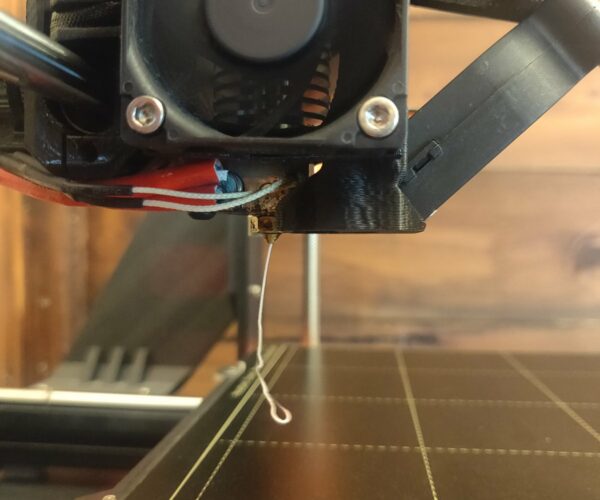

I'm pretty new at this, but I typically preheat everything before starting a print and just pick off the string with my fingers. If it's really short, I use a short piece of filament I have laying on my table and "flick" it off. Happens all the time...

Ted

RE: Filament Problem

There is a common method to preheat only so far then run the bed level. By not heating to full print temp, you can avoid the entire drool/gnat problem.

The following is my code - its not plug and play for everyone, but the comments should guide you to the important parts to add to your own custom startup gcode. The M109 R175 ; wait for extruder temp is the key line.

M115 U3.9.1 ; tell printer latest fw version

; printer specific Printer Start Gcode

M862.3 P "[printer_model]" ; printer model check

M862.1 P[nozzle_diameter] ; nozzle diameter check

{if print_settings_id=~/.*(DETAIL @MK3|QUALITY @MK3).*/}M907 E430 ; set extruder motor current{endif}

{if print_settings_id=~/.*(SPEED @MK3|DRAFT @MK3).*/}M907 E538 ; set extruder motor current{endif}

; generic Printer Start Gcode

G90 ; use absolute coordinates

M83 ; extruder relative mode

; M104 = set hot end temp

; M109 = wait for hot end temp <Sxxx and Rxxx interchangable>

; M140 = set bed temp

; M190 = wait for bed temp <Sxxx ignores too hot, and Rxxx waits for heats or cools as needed>

; cool down PINDA

M106 S255 ; turn on fan

M104 S0 ; turn off nozzle heat

M140 S0 ; turn off bed heat

M860 S35 ; wait until PINDA is less than 35C

M106 S0 ; turn off fan

; preheat nozzle to a low temp, get plastic mushy before driving into the bed with G28

M140 S[first_layer_bed_temperature] ; set bed temp

M109 R175 ; wait for extruder temp

M190 R[first_layer_bed_temperature] ; set & wait for bed temp

G28 W ; home all without mesh bed level

; soak PINDA then level

G0 X50 Y50 Z1 F3000; this is a good PINDA heating position

M860 S37.5 ; wait until PINDA is >= 35C in winter, 37.5C spring/fall, 40C summer

G80 N7 R5; mesh bed leveling

; heat to extrude temp

G0 X0 Y-3.0 Z10 F3000; this is a good nozzle heating position

M109 R[first_layer_temperature] ; set & wait extruder temp

; purge

G1 Y-3.0 Z0.20 F1000.0 ; go outside print area

G92 E0.0

G1 X1.0 Y-1.0 E0.5 F500.0 ; scribble 1

G1 X1.0 Y-3.0 E0.5 F500.0 ; scribble 1

G1 X2.0 Y-1.0 E0.5 F500.0 ; scribble 2

G1 X2.0 Y-3.0 E0.5 F500.0 ; scribble 2

G1 X3.0 Y-1.0 E0.5 F500.0 ; scribble 3

G1 X3.0 Y-3.0 E0.5 F500.0 ; scribble 3

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.0 F1200.0 ; intro line

G1 X97.0 F2000.0 ; wipe left

G1 X105.0 F3000.0 ; wipe right

G92 E0.0

; reduce extrusion rate for normal layer heights

M221 S{if layer_height<0.075}100{else}95{endif}

; end Printer Start Gcode

RE: Filament Problem

@christos-2

I'm genuinely curious, you managed to build an enclosure and print the support leg for your printer frame and apparently the parts for the rest of the enclosure? install them to the point that your printing in it, and now your asking about something as basic as how to preheat your printer?

what happened?

Regards

Swiss_Cheese

The Filament Whisperer

RE: Filament Problem

@swiss_cheese

HI ,

I dident ask how to preheat my printer , the problem start after the preheat and when measuring the points

RE: Filament Problem

@technical-ted

I would use tweezers to clean off the filament dribble. As you get to more exotic filaments, you will risk a burn.

--------------------

Chuck H

3D Printer Review Blog

RE: Filament Problem

@cwbullet

Thanks for the advice. I'm curious... did you modify your start code or do you simply preheat then remove the dribble with tweezers? What's the most common way of dealing with the dribble. There's more than one way to skin a cat and I'm curious how others do it. This should help the OP as well...

Thanks Ted

RE: Filament Problem

@technical-ted

In general, I do not have to remove it because it is automatically removed when it hits the “wipe line” on the front edge of the bed. If it is longer, I will remove it.

I am not sure what you call that line. I searched once and could not find a a term. I did see some guy call it an “intro line”.

--------------------

Chuck H

3D Printer Review Blog

RE: Filament Problem

Often called a 'prime line' as it is used to prime the extruder prior to printing.

The outline 'skirt' was commonly used to do the same thing on other printers in the past. If using a prime line like the prusa printers do then you don't really need a skirt although it is still useful to double check your z tuning and also that the print area fits properly and is what you were expecting.