Re: Filament jams in heatbreak.

I bought a swiss heatbrake as well, waitng for it to arrive. Will report back after i install it.

Re: Heat Break disease.

So my question is which way should I proceed. I see the choices as

1. Just buy replacement heat break from Prusa or Filastruder ( the US E3d stockists, good people). I could buy the modified one for the Mk3

2. or try to revert to the one where the PTFE goes all the way through.

3. I could buy the Swiss heatbreak.

4.I could just buy a whole new hot end.

5. Any other?

I am interested in the advice of this group. ❓

1. The mk3's heatbreak possibly has an issue. I would worry about a replacement from Prusa. A "normal" E3D heatbreak will work fine.

2. I wouldn't go this way. you are looking at losing ability to print at high temps, and possibly more issues.

3. I would do this one. The Micro Swiss, is designed optimally in my opinion.

4. This would be expensive, and your issue is either. 1. Nozzle. 2. heatbreak. 3. PTFE tube. Why replace everything?

5. Not really, seems you covered everything with 1-4. 🙂

I borrowed sean.h8 picture from page 3(i hope you don't mind)...

Wouldn't be better to have diameters in heatbreak other way so the heatbreak shape filament to 1.9mm diameter and not a teflon tube..

I don't mind at all, I stole it from some other site... LOL! 🙂

Your idea looks VERY much like this.

I'm unsure what the ID is on that, however I would assume it's 2mm at the top, and 2.1mm at the bottom.

Basically the same idea as yours except 2.0 and 2.1, instead of the 1.9 and 2.0 you said.

The 1.9 is in theory relevant for "blob control" regarding the MMU. The "huge game-changer" problem however, is.. I got worse blobs with the 1.9mm than the 2.0mm. (explain that one?!?!?!?)

The image I just linked in the Micro Swiss 1.75mm heat break (Thermal tube)

As far as I can tell, the "Original" E3D v6 hotend, is "straight" with 2mm all the way through.

(And I'm not 100% sure if the PTFE inside the hot-end is 1.9mm, it could be 2mm)

Although I know mine's 1.9mm... Capricorn baby!!! 😈

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Filament jams in heatbreak.

Besides the heatbrake, would changing the noctura fan to a higher speed fan help?

Re: Filament jams in heatbreak.

Besides the heatbrake, would changing the noctura fan to a higher speed fan help?

I'm not sure honestly, I don't have a thermal camera. If I did, I would be all over imaging where the heat is, and how much.

If you are in an enclosure, a bigger/faster/whatever fan where the Noctura is, would likely be good though.

Although not in an enclosure, I can tell you the bottom fins on the heat-sink, are not "hot" they are not even really "warm". Kinda like the perfect "bath" water temp?

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Filament jams in heatbreak.

Besides the heatbrake, would changing the noctura fan to a higher speed fan help?

My point exactly. I have an upgraded MK2.5 with the same issues as described in this thread, yet everything worked before the upgrade. That IMHO means that the MK2 heatbreak has the same problems the MK3 heatbreak has and the connection between the two is the noctua fan. Or is the very same heatbreak used in both MK2 and MK3?

I suppose the Micro Swiss heatbreak does help with this problem and I am looking into buying one too, just to try it out even. I just fear the heatbreak might be an overall improvement that irons over the actual problem at hand. Meaning that if we get everything running before changing the heatbreak then changing the heatbreak might further improve print quality.

Just my 2 cents.

-DerBierBaron

Re: Filament jams in heatbreak.

Did you have a standard MK2 or an MMU? The MMU introduced a new heat break design that I think brought these problems with it.

Re: Filament jams in heatbreak.

I only have the standard version.

Re: Filament jams in heatbreak.

I suppose the Micro Swiss heatbreak does help with this problem and I am looking into buying one too, just to try it out even. I just fear the heatbreak might be an overall improvement that irons over the actual problem at hand. Meaning that if we get everything running before changing the heatbreak then changing the heatbreak might further improve print quality.

Just my 2 cents.

-DerBierBaron

When did you get your mk2s? Someone said that the "new" mk2s has the same heatbreak in it.

There's two types of fixes and problems in the world.

Problem 1.

The kind of problem that has more than one way to fix.

Problem 2.

The kind of problem that has only one way to fix.

Solution 1.

The kind of solution that is absolute, and is the ONLY solution to the problem.

Solution 2.

The kind of solution, that has many solutions.

To understand which of these problems it is, you need to understand the actual problem.

Problem: Heat is creeping into the heatbreak, causing a forward jam.

Solution(s?)

Solution 1. Keep the heatsink colder (bigger fan), this will cool the heatbreak, and reduce the chance of heat creep causing a jam.

Solution 2. Use a heatbreak, that does not have a design that can "forward jam" due to minor heat creep.

Now both of these are not needed, and one is actually more practical than the other.

The bigger fan is a nice idea, and it might work. However what happens if ____ happens, and the fan has ____ issue, and the heatsink gets a touch warm again... (say, cat-hair got in it or something)... You now have a shiny new jam.

Replacing the heatbreak with a better design, that does not "forward jam", is the ultimate solution.

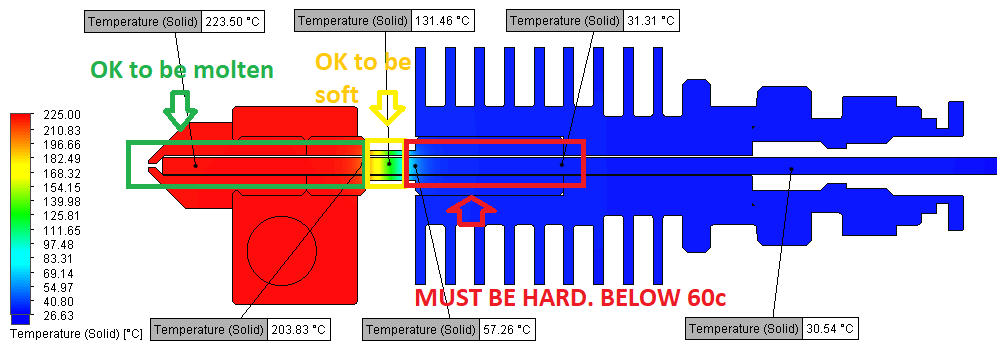

The issue with the MMU heatbreak is that if the heatsink gets "warm" it will jam. This could be caused by many things. With where the step is, you see it's already VERY close to the "glass transition" of PLA according to these images.

If you were to look at (in THEORY) a heat break that can not jam going forward... So long as the filament is above glass temps at the transition between PTFE and Heatbreak, you are FINE. Compare the MMU failure point, to the "theoretical" failure point of a *NORMAL* one.

I think the microswiss and standard E3D will fit in the "Theory" point.

EDIT:

Replacing the fan with a bigger one, simply makes it work, but it does not fix the problem.

Replacing the heat-break, simply fixes the problem.

One of my favorite quotes.

Is it a Symptom, or is it the problem?

Symptom: Heat creep.

Problem: Heat break designed poorly, and VERY susceptible to heat creep.

Solutions:

Best: Replace heat-break with properly designed heat break.

Ok: Replace Fan with over-spec fan, to reduce failure rate of poorly designed heatbreak.

EDIT2: The "gap" between the heat block, and heatsink, are supposed to be ~5mm. Assuming that, and a 1mm retraction, that means that retraction will retract the filament up 20% of the "neck". So really if the "soft" zone gets to 50% of the neck, you are inviting failure, on the MMU variant.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Filament jams in heatbreak.

Hey Sean,

thanks for the detailed reply.

I received my MK2S Kit in the middle of July 2017 (no clue as to how new mine might be considered though regarding the heatbreak 😀 )

I fully agree that having a heatbreak that ensures PLA to stay at just about its glass transition temperature above the neck part is all it would need to fix these jams.

I also haven't tried the micro swiss heatbreak yet, which could very well solve the problem.

My points were mainly focused around the fact that Prusa sold this system in a working condition to me and usually I'm a fan of never touching a running system (as long as it fulfills its duty). Basically the approach the Prusa team must have gone back with the old design, was to use the heatbreak that way and spec out the fan for sufficient cooling.

I once had a completely jammed heatbreak before, meaning that PLA melted all the way through the heatbreak.... That of course is most likely due to using a well insulated enclosure... but that was before the noctua upgrade as well.

So you might understand that I do get the point of finding the root of a problem but I don't think it's black and white in this case but more... grey

I don't mean to say that the micro swiss heatbreak alone can't solve the problem for most cases reported, I merely would like to say that I have had major issues with insufficient active cooling before and after researching on the internet found more similar cases that supported my theories to some extend.

I realize that I'm asking a lot from my printer, wanting it to be able to print most materials on the market. But that's one of the reasons I bought my Prusa: with the right amount of effort most materials can be printed on it, though printing more high temperature materials means more compromise on the lower temperature end as well (mostly speaking of the enclosure...)

Tell you what: I will try out the micro swiss heatbreak and test it with the enclosure open and closed as well (usually ambient temperature won't rise above 35°C in there with PLA) and report my findings 🙂

Regards,

DerBierBaron

P.S.: If anyone is interested how I cleaned the fully clogged heatbreak: after removing it and finding it as the culprit, I put it in a vice with aluminum jaws, heated it up with a heatgun and pushed the majority of the filament out with a cocktail stick. The remaining PLA was removed by first soaking the heatbreak in acetone for a couple of hours and then with brushes, cocktail sticks, whatever fit in there and was a soft-ish material to avoid marring the inner surface 🙂

Re: Filament jams in heatbreak.

I just got the swiss heatbrake! Could anyone teach me how to apply the thermal compound?

Re: Filament jams in heatbreak.

I just got the swiss heatbrake! Could anyone teach me how to apply the thermal compound?

Nothing fancy. Just apply a couple small dabs (2-3 cubic millimeters total is plenty) and screw it in to the heatsink.

Unrelated: I do have a thermal camera, and it's bee pretty helpful in figuring out fan speeds to optimize curling vs adhesion.

Re: Filament jams in heatbreak.

I just got the swiss heatbrake! Could anyone teach me how to apply the thermal compound?

Nothing fancy. Just apply a couple small dabs (2-3 cubic millimeters total is plenty) and screw it in to the heatsink.

Unrelated: I do have a thermal camera, and it's bee pretty helpful in figuring out fan speeds to optimize curling vs adhesion.

where do i dab it though? would it overflow into the inner chamber after I screw it into the heatsink?

Re: Filament jams in heatbreak.

where do i dab it though? would it overflow into the inner chamber after I screw it into the heatsink?

Just a few "drops" so to say, on the first few threads that go into the heatsink. do not put thermal compund on the hot-end side.

Kinda like this.

If you are worried (you are right about this) about it getting into the inner chamber, put it 2-3 threads below the "top", if you don't trust yourself/others.

It literally only takes a tiny amount..

Honestly, I don't know if it's 100% necessary. But I agree that it does help.

PS: Do not use two impact wrenches to tighten, as seen in the video. It does not need to be very "tight" at all. Follow the instructions on the E3D V6 site... too tired to look it up, and bedtime. 🙂

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Filament jams in heatbreak.

I've also ordered a swiss heatbreak due to my continued issues with my hotend that persist despite nozzle changes and making sure the extruder gears and other settings aren't the issue.

I've checked out the E3D-v6 assembly guide here: https://wiki.e3d-online.com/E3D-v6_Assembly and I'm wondering if there are any specific changes to that assembly guide when it comes to removing the custom Prusa v6 heatbreak and installing the swiss heatbreak. To me it seems like I should first heat and remove the nozzle, then remove the entire hotend from its enclosure, and unscrew the heat block from the other components, unscrew the current heat break, screw on the swiss heat break, screw it into the heat block, replace it on the printer, then heat it up and replace the nozzle. Does this sound correct?

As far as I know the heatbreak alone will not come with thermal compound. If it's recommended, what type or brand of thermal compound should be used?

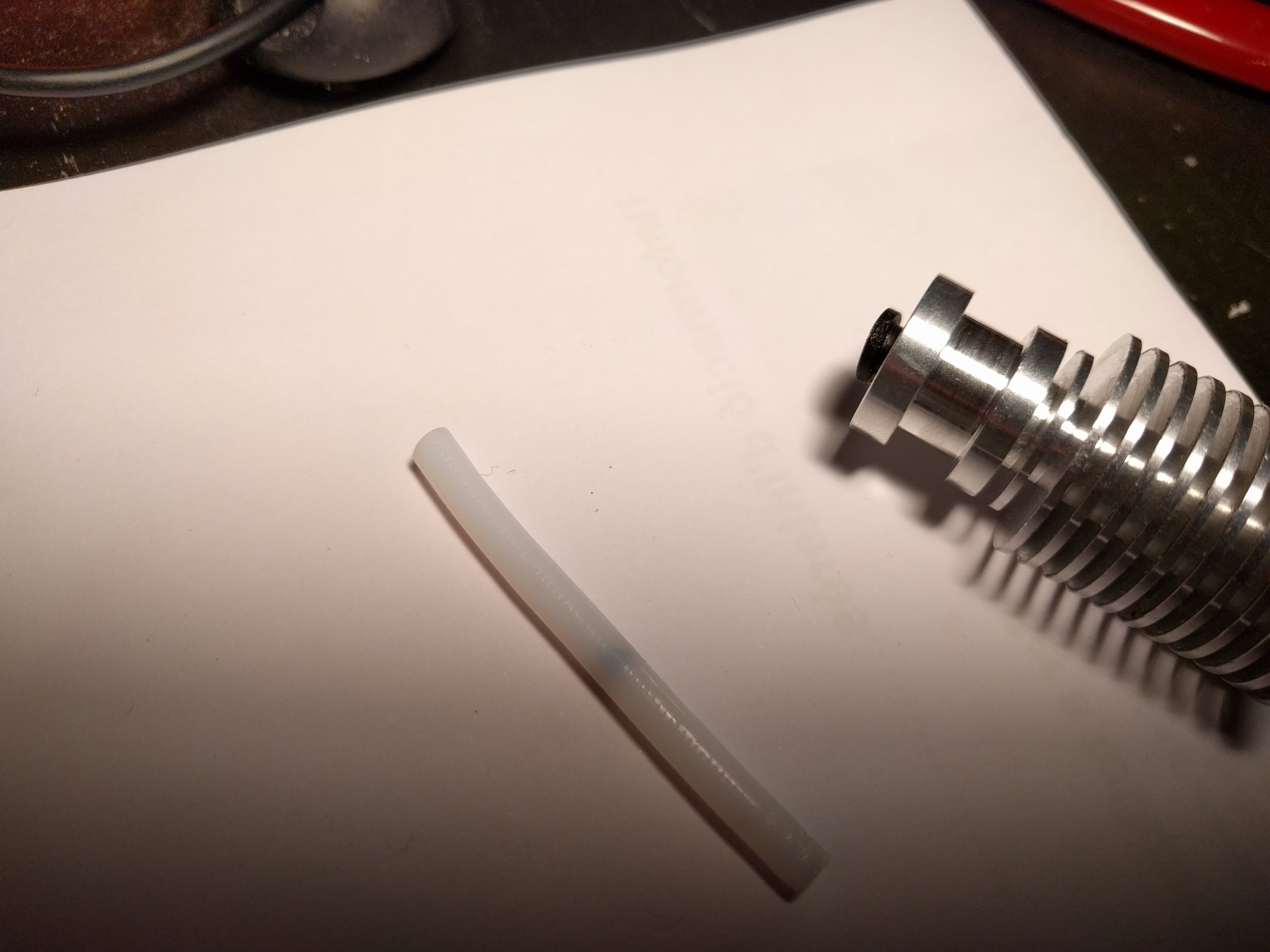

I remember from disassembling my first faulty Prusa hotend that the bowden tube Prusa uses seemed to have had a "head" to it and wasn't just a plain cylinder all the way through. I'm attaching an image of the bowden tube from my first Prusa hotend, notice the thick line and tiny translucent thinner bit of tubing coming from the tip. Hopefully this does not cause any issues when fitting into the swiss heat break.

Re: Filament jams in heatbreak.

Hi @austin.a2 my prusa mk3 (purchased january, shipped march) did not have a head. The tube was just a cilinder:

For me it was easier to remove the heat sink by removing the heat block first because otherwise the cable impeded me to pull the heat sink at the angle required to remove it

Re: Filament jams in heatbreak.

I've also ordered a swiss heatbreak due to my continued issues with my hotend that persist despite nozzle changes and making sure the extruder gears and other settings aren't the issue.

I've checked out the E3D-v6 assembly guide here: https://wiki.e3d-online.com/E3D-v6_Assembly and I'm wondering if there are any specific changes to that assembly guide when it comes to removing the custom Prusa v6 heatbreak and installing the swiss heatbreak. To me it seems like I should first heat and remove the nozzle, then remove the entire hotend from its enclosure, and unscrew the heat block from the other components, unscrew the current heat break, screw on the swiss heat break, screw it into the heat block, replace it on the printer, then heat it up and replace the nozzle. Does this sound correct?

As far as I know the heatbreak alone will not come with thermal compound. If it's recommended, what type or brand of thermal compound should be used?

I remember from disassembling my first faulty Prusa hotend that the bowden tube Prusa uses seemed to have had a "head" to it and wasn't just a plain cylinder all the way through. I'm attaching an image of the bowden tube from my first Prusa hotend, notice the thick line and tiny translucent thinner bit of tubing coming from the tip. Hopefully this does not cause any issues when fitting into the swiss heat break.

You need to get some replacement Bowden. That will not work. I recommend Capricorn.

Re: Filament jams in heatbreak.

As far as I know the heatbreak alone will not come with thermal compound. If it's recommended, what type or brand of thermal compound should be used?

I remember from disassembling my first faulty Prusa hotend that the bowden tube Prusa uses seemed to have had a "head" to it and wasn't just a plain cylinder all the way through. I'm attaching an image of the bowden tube from my first Prusa hotend, notice the thick line and tiny translucent thinner bit of tubing coming from the tip. Hopefully this does not cause any issues when fitting into the swiss heat break.

Correct, does not come with any compound.

I used THIS Not gonna say it's the best... but it's the cheapest that seemed to have good reviews.

That "head" is *NOT* normal. Either you had some major heat creep, or, something pressing down on it VERY hard from the top to deform it like that. I would guess heat-creep, in the neighborhood of 200 to 220c.... which is crazy high.

As far as instructions go. The Prusa heat-break, is identical on the outside compared to the "stock" E3D. As is the Micro Swiss. The ONLY differences are on the INSIDE (filament path).

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Filament jams in heatbreak.

Hey Sean,

Any chance of you printing another single wall cube with this new heatbreak? Just curious if this has any relation to our inconsistent extrusion issue (i.e., small amount of friction/backpressure that consistently hits a "breakover" point and gives us the random yet consistent blobs). I understand this has nothing to do with the moire. 🙂

Thanks!

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Filament jams in heatbreak.

FYI, I have installed the microswiss heat-break and printed a single-extrusion-wall 20-mm cube. No difference for me. I'm testing the heat-break jam issue now on a print that consistently exhibited the issue. Fingers crossed.

Re: Filament jams in heatbreak.

After swapping with the swiss heatbrake, no issues! No more jams, no more under-extrusions! 🙂