Filament broke off in extruder

During a print, the filament (ABS) came off the holder and got wound around and stuck. it then broke right at the top of the extruder, just coming out of the PTFE tube. I can't push it through for anything, it seems like there is a blob at the top, but not enough to grab on to and pull out.

What are my options? I presume I have to dismantle the extruder though I'm not sure I'll be able to get it out even then. Any thoughts?

Re: Filament broke off in extruder

During a print, the filament (ABS) came off the holder and got wound around and stuck. it then broke right at the top of the extruder, just coming out of the PTFE tube. I can't push it through for anything, it seems like there is a blob at the top, but not enough to grab on to and pull out.

What are my options? I presume I have to dismantle the extruder though I'm not sure I'll be able to get it out even then. Any thoughts?

Okay, here's the worst-case scenario: You'll have to disassemble the extruder and heat sink, use a drill to remove the filament and the PTFE tube and replace the PTFE tube. Fortunately, a replacement PTFE tube only costs a couple bucks (plus shipping).

Before you get to that point, there's a couple more things to try.

First, I'd try: heat the extruder really hot (over 260), remove the nozzle, and use something like a thick paperclip or 1.5mm drill bit to try to push the stuck filament through.

If that doesn't work, try disassembling the hot end from the heatsink and see if you can find and remove the jam without destroying the PTFE.

Re: Filament broke off in extruder

No need to tear everything apart if it's just stuck. Try this:

Open up the extruder housing using the 2 screws on the left as viewed from the front. You may be able to see the filament sticking out of the PTFE tube below the extruder gears. Try to pull it out with needle-nose pliers or tweezers. Be careful not to mangle the PTFE tubing sticking up from below. LOOK CAREFULLY before you start poking about or yanking on things.

If you can't reach it, and you have the proper tools available, do this:

If you got it, re-assemble everything in reverse order and carry on.

I've got pics here, except inserting the wrench/rod from above. You'll want to try to push from below.

Re: Filament broke off in extruder

Thanks for the tips. The idea of clearing the jam without completely disassembling the extruder greatly appeals to me as you can imagine.

There isn't nearly enough of the filament to grab on to, as you can see in the image there's just a little ball sticking out of the top of the PTFE tube.

I took off the nozzle as described. But when I tried to push through with a 1.5 mm key, it wouldn't budge. Should I dare go hotter than the 250C recommended (This is ABS by the way)? Or does that mean it's not going to come out without disassembly?

Thanks again!

Re: Filament broke off in extruder

with the extruder at max Z height, there should not be any problems pushing the nozzle to 295c, for a short while,

remove the nozzle let the extruder sit for a short while, say two minutes then try your 1.5mm allen key up the extruder. mind your fingers don't touch the heater block.

as soon as you get some movement, remove the Allen key, and try removing the filament from the top with long nose pliers.

if successful, drop the temperature to a more normal level, clean off the filament remains, check the nozzle is clear and reinstall.

if the nozzle is not clear, try holding the nozzle in pliers in the hot air from a hot air blower/ paint stripper, and try clearing the nozzle with a short piece if filament... when clear, re install the nozzle.

if you have a spare nozzle of the correct size, you could fit that, and put the old nozzle in a jar, with a little acetone, to dissolve the old ABS, screw the lid back on to keep the acetone safe, and return the cleaned nozzle to your spares container when clean.

before starting printing, check and adjust live if necessary, even with the original nozzle, the level could be different

be safe, take precautions you fingers, furniture, clothing, skin and floor furnishings are at risk if you drop hot plastic, or hot metal, consider working over something heatproof!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Filament broke off in extruder

Dang, Even with the nozzle at 295 I can't get it to budge. I think I'm stuck with disassembling the extuder. I fear that even with it disassembled I will not be able to clear this jam.

Re: Filament broke off in extruder

Well, things have gone from bad to worse. I got the extruder out in the open, and cut off the little nub at the top of the PTFE tube that was blocking it from moving. I heated it up to see if I could push the jam out, but without the fan I melted the black ring that locks in the PTFE tube 🙁

Is that something that can be replaced or am I screwed?

Re: Filament broke off in extruder

Black ring can be replaced

So can ptfe. If necessary

There are e3d resellers in many places.

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Filament broke off in extruder

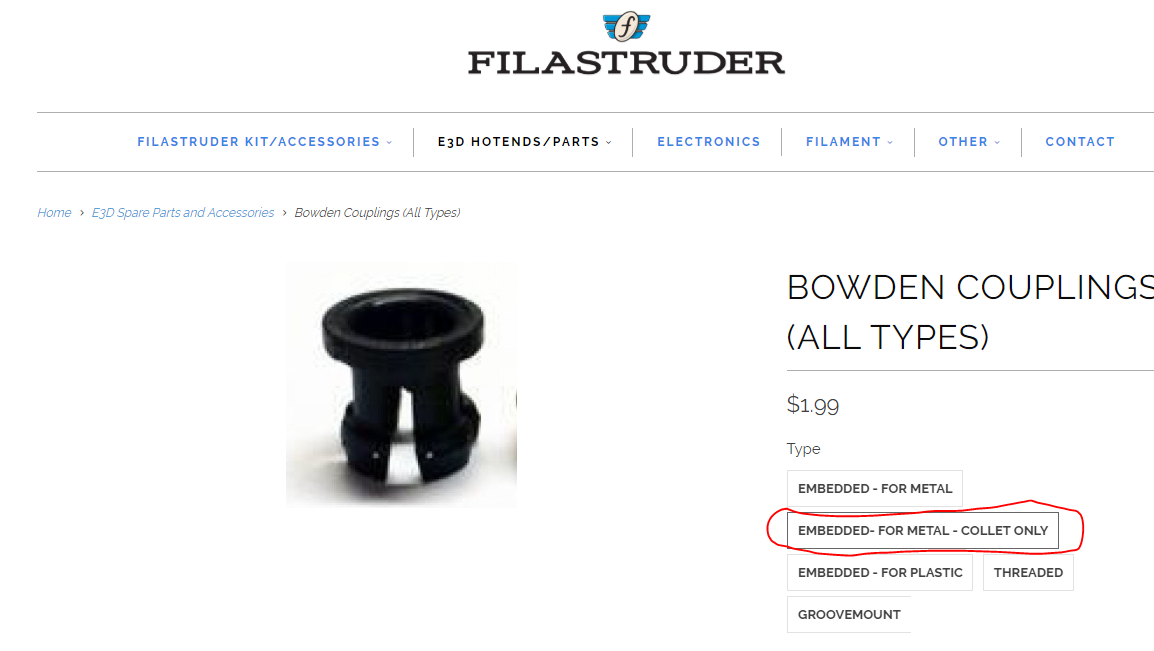

Looks like the PTFE is easy to find, but I'm having trouble with the black ring, partly because I don't know what it is called. Does any one know what the part I need is?

Re: Filament broke off in extruder

Looks like the PTFE is easy to find, but I'm having trouble with the black ring, partly because I don't know what it is called. Does any one know what the part I need is?

It would be helpful if we knew what country you were in so we could send you to the appropriate reseller. That being said, the black ring piece is a collet. In the USA you can find them at https://www.filastruder.com/collections/e3d-spare-parts-and-accessories/products/bowden-couplings-all-types?variant=32354109764

Re: Filament broke off in extruder

Hi,

Sorry for not giving out my location; I'm in Portland, Oregon USA. So the link you sent was great, and I got both those items on order.

Thanks so much!

This worked for me!

I had PLA that got stuck there after breaking off due to a tangle. I heated to 230, used the small wrench to push the initial filament through. I then pushed with the new PLA which now had a place to go and melt. Keep pushing it through until you’re confident the new PLA is what is coming out. From there, do a cold pull. (cooldown, keep pushing manually until 170, wait for room temp, heat to 85, and pull out filament w/ pliers immediately after hitting). Hope this helps avoid the hassle seen above!

RE:

I just resolved this issue by removing the hot end and clearing the PTFE tube. while doing so I though why didn't I take a guitar string and push it up through the nozzle. It's thin enough and strong enough that it might be able to push out something lodged in the tube. I'm gonna try this the next time it happens.