Re: Does someone want to know how fast they can print/extrude? look here

I have made no changes to firmware. I do have an experimental X-carriage but if any thing that would slow things down as the current version binds slightly.

My print settings were as follows for the final test:-

Layer height 0.2mm

First layer 0.3mm

Perimeters 1

Spiral Vase

No solid layers top or bottom

No infill

Brim Width 5mm

First layer speed 15mm/s

Extrusion width 0.45mm

Acceleration all at 800mm/s²

Max print speed 500mm/s (Must be why I heard no change between 500 and 550mm/s)

First layer 220°C

Other layers 245°C

Bed 85°C First layer

Bed 90°C other layers

Fan disabled first 3 layers then 30% to 50%

Max volumetric speed 120mm³/s

K value 60

0.2mm Z offset

Start G-Code

M115 U3.2.1 ; tell printer latest fw version

M201 X4000 Y4000 Z200 E5000 ; sets maximum accelerations, mm/sec^2

M203 X400 Y400 Z12 E120 ; sets maximum feedrates, mm/sec

M204 S1250 T1250 ; sets acceleration (S) and retract acceleration (T)

M205 X2 Y2 Z0.4 E2.5 ; sets the jerk limits, mm/sec

M205 S0 T0 ; sets the minimum extruding and travel feed rate, mm/sec

M83 ; extruder relative mode

M104 S160 ; set extruder temp

M140 S[first_layer_bed_temperature] ; set bed temp

M190 S[first_layer_bed_temperature] ; wait for bed temp

M109 S160 ; wait for extruder temp

G28 W ; home all without mesh bed level

G80 ; mesh bed leveling

G1 Z35.0 ; Move up before heating to temp

G1 Y-3.0 F1000.0 ; go outside print area

M104 S[first_layer_temperature] ; set extruder temp

M109 S[first_layer_temperature] ; wait for extruder temp

G1 Z[first_layer_height] ; Lower to print first layer

G92 E0.0

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.5 F1000.0 ; intro line

G92 E0.0

M221 S{if layer_height==0.05}100{else}95{endif}

End G-Code

G4 ; wait

M221 S100

M104 S0 ; turn off temperature

M140 S0 ; turn off heatbed

M107 ; turn off fan

{if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+30, max_print_height)}{endif} ; Move print head up

G1 X0 Y200; home X axis

M84 ; disable motors

Before Layer change G-code

;BEFORE_LAYER_CHANGE

G92 E0.0

;[layer_z]

After Layer change G-code

;AFTER_LAYER_CHANGE

;Layer Z value [layer_z]

; gotta go fast

;Layer number [layer_num]

{if (layer_num - (layer_num / 25) * 25) == 0}M220 S{layer_num*2+100}{endif}

The g-code from my final test

As you can see there is nothing special in my settings that should make my test hit a higher speed than yours.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Looks as though you are counting each layer as increasing by 50mm/sec, whereas I've been counting them as increasing by 25mm/sec. I guess we should both double check the gcode, as we can't both be right. That might explain how you got to 500mm/sec, whereas your speed test print doesn't look as though it's that high.

Devilhunter's speed increase G-Code. Each speed increase is clearly a step of 50mm/s. Each change is 5mm above the one before

; gotta go fast

{if layer_z > 5 and layer_z < 6}M220 S150{endif}

{if layer_z > 10 and layer_z < 11}M220 S200{endif}

{if layer_z > 15 and layer_z < 16}M220 S250{endif}

...

and so on

My speed increase G-Code it increases the speed every 25 layers by 50. So with a layer height of 0.2 that is again 50mm/s increase for every 5mm in height

; gotta go fast

;Layer number [layer_num]

{if (layer_num - (layer_num / 25) * 25) == 0}M220 S{layer_num*2+100}{endif}

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Devilhunter's speed increase G-Code. Each speed increase is clearly a step of 50mm/s. Each change is 5mm above the one before

; gotta go fast

{if layer_z > 5 and layer_z < 6}M220 S150{endif}

{if layer_z > 10 and layer_z < 11}M220 S200{endif}

{if layer_z > 15 and layer_z < 16}M220 S250{endif}

...

and so on

That's the disconnect. According to Marlin ( http://marlinfw.org/docs/gcode/M220.html ), M220's gcode argument is a feedrate percentage, not a feedrate in mm/sec as you seem to imply. In his OP, DevilHunter provides a table for converting feedrate percentage into mm/sec for each 5mm layer set:

Your Results will be:

100% speed OK = 50mm/s

150% speed OK = 75mm/s

200% speed OK = 100mm/s

250% speed OK = 125mm/s

300% speed OK = 150mm/s

350% speed OK = 175mm/s

400% speed OK = 200mm/s

450% speed OK = 225mm/s

500% speed OK = 250mm/s

550% speed OK = 275mm/s

600% speed OK = 300mm/s

650% speed OK = 325mm/s

700% speed OK = 350mm/s

750% speed OK = 375mm/s

800% speed OK = 400mm/s

850% speed OK = 425mm/s

900% speed OK = 450mm/s

950% speed OK = 475mm/s

999% speed OK = 499.9mm/s

[Edit: Unrelated to the above, but I have a new hypothesis, which is that untinted PETG may print the fastest of all (or, put differently, print the best as these high speeds). The theory would be that there would be no particles of pigment to impair the layer adhesion. So, if anyone reading this already has some untinted PETG laying around, you may want to give it a try and see how it compares.]

Re: Does someone want to know how fast they can print/extrude? look here

OK first here are my results from the last test recalculated from percentage to speed.

50mm/s -100% full glossines was achieved. The previous test was not quite there.

75mm/s - 150% still very glossy but starting to fade.

100mm/s 200% gloss is reduced but good enough for a draught print

125mm/s 250% is good enough for infill

150mm/s 300% fully bunded and without an extrusion problems

175mm/s 350% under extrusion is in full force but bonding. This however is unacceptable even on infill

250mm/s 500% Same as 300. Measured wall width 0.61mm

So using 150mm/s as the maximum extrusion speed this gives a volumetric limit of around 13mm³/s (150mm/s) up from my current profile of 8mm³/s (64mm/s approx). This is still a major linear speed increase on infill and supports of 135% over double of the current profile I am using.

Or just going with my original print temperature so I have minimal ooze a volumetric limit of 11mm³/s (125mm/s) also up from my current profile. This is still a major linear speed increase on infill of 95% (37.5% volumetric)

So the found profile only listing changes from Prusa default Slic3r values for PETG is:

Print temperature 220/230°C (Stay at this for reduced ooze)

Max volumetric speed: 11mm³/s (Old value 8mm³/s)

Z offset 02.mm

First layer height 3mm

Top solid infill 35mm/s (To match the external perimeter quality)

First layer speed 15mm/s

First layer acceleration 500mm/s

So only on prints with infill will the speed increase be apparent all in all a worthwhile experiment with PETG printing at 62% the default speed of PLA instead of 32%. Now to run an actual print with the new profile as a final check 🙂

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Thank you for your excellent summary, Martin. So, apparently for you, PLA trumps PETG if you want to get acceptable prints as fast as possible.

Just to confirm: these results are with both copper nozzle and copper volcano hot end, correct? With or without silicon sock?

Re: Does someone want to know how fast they can print/extrude? look here

My results are for a standard V6 plated copper block and nozzle without sock. Basically was trying to push the standard setup for comparison with Volcano results.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

My results are for a standard V6 plated copper block and nozzle without sock. Basically was trying to push the standard setup for comparison with Volcano results.

Regards,

Martin

Ahhhhh, it all makes sense then. When do you think you'll be upgrading to Volcano? As you say, it will be interesting to see how the performance of your standard setup compares to your Volcano setup.

Re: Does someone want to know how fast they can print/extrude? look here

[...] My results are for a standard V6 plated copper block and nozzle without sock.

This was with a plated copper nozzle as well?

Re: Does someone want to know how fast they can print/extrude? look here

Yes it was. Having some first layer problems with the plated copper nozzle and block on real prints.

Although PETG does not stick as much as with a brass one it is disturbing the first layer and ripping it. Adding a sock improved the situation but has not solved it. So now I am trying with sock and first layer speed of 7mm/s and X-Y first layer jerk of 0 raising back to 10 on the higher layers.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

I've ordered some "natural" untinted PETG and PLA to see if they have better layer adhesion, as per the hypothesis I posted earlier today. Perhaps they will turn out to be the filament of choice for high speed printing.

Seems like together we're making good progress! 😀

Re: Does someone want to know how fast they can print/extrude? look here

Grr forgot to actually hit submit on a post I was making after previewing it. Now lets see if I can remember what I wanted to say. 😛

-----------------------------------------------------------------------

The 7mm/s, 0 x-y jerk and sock combination solved my first layer problems. The jerk was raised back to 10 for the following layers.

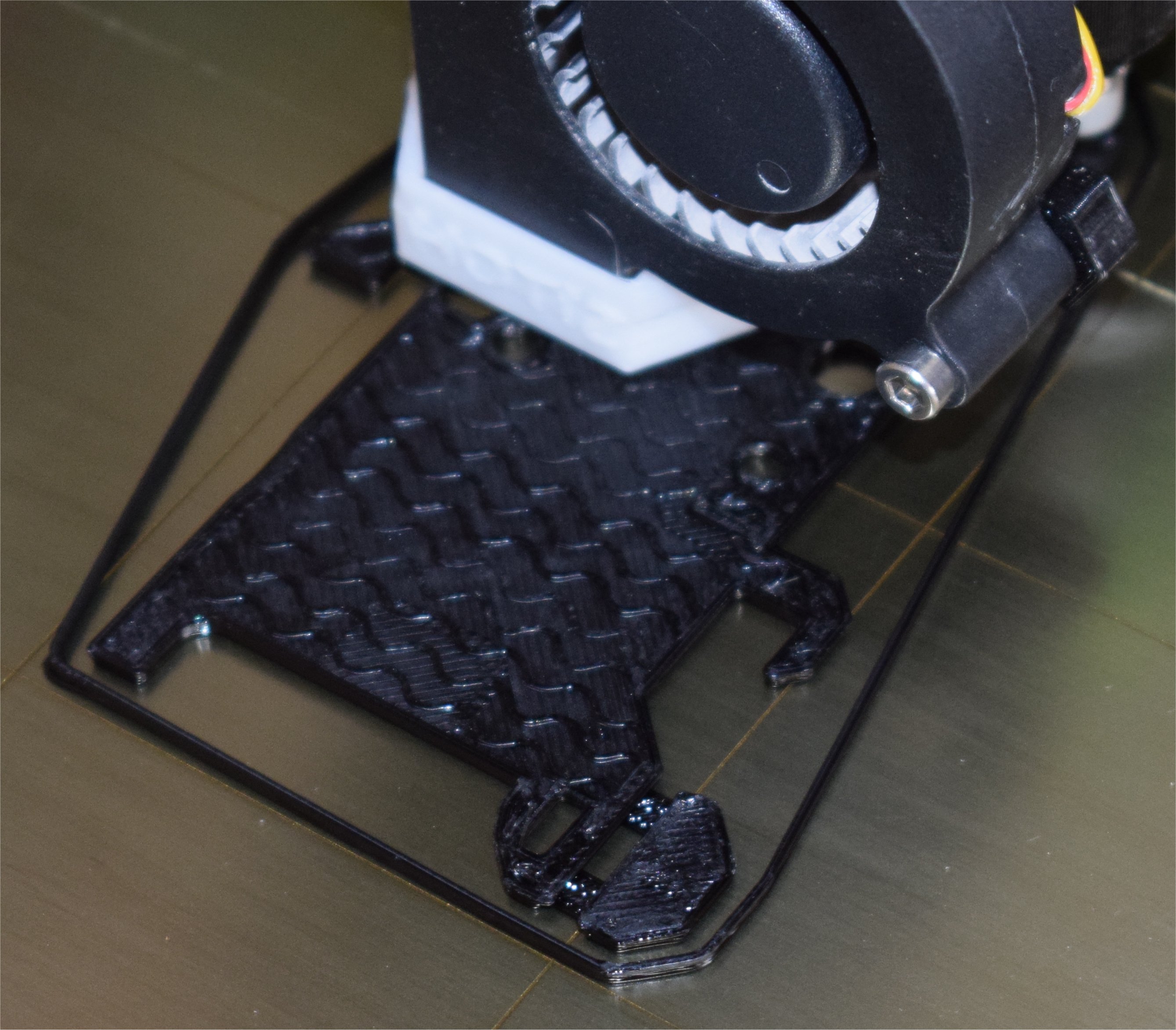

Now the result :). All in all the practical test is going well:-

When the current print is finished I will run some speed testes with the sock.

1st test will be K=45, 220°C/230°C and a jerk of 5

2nd test will be K=60, 220°C/245°C and a jerk of 5

Not really expecting much of an improvement with the sock on the copper block/nozzle combo but I'll see what happens.

Then I'll remove the sock and see if just the 7mm/s first layer speed was enough to cure the problem or weather I really needed it to work with a 7mm/s first layer speed.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Would putting higher torque nema17's in place of the existing X and Y (and maybe Z) stepper motors allow us to achieve higher acceleration rates? They are fairly inexpensive, and they would be drop-in replacements, provided that the control board could drive them with enough current. It occurs to me now that it might be an even easier upgrade than the skelestruder, which would only provide advantage on the X and Z axis and do nothing for the Y axis.

I'm not knocking the skelestruder, though, which seems like a very nice design, regardless, and which one may still want to do anyway.

Re: Does someone want to know how fast they can print/extrude? look here

Not sure if higher torque motors would be worthwhile. In the PETG test I was only running at an acceleration of 800mm/s² and the default Slic3r acceleration for infill is 1500mm/s²

So in my tests the extruder travelled just 25mm with an acceleration of 800mm/s² to reach 200mm/s in 0.25s.

To reach 200mm/s at an acceleration of 1500mm/s² (Slic3r's default infill acceleration,) takes 0.13333s and covers 13.33mm

Assuming with upgraded motors 3000mm/s² is possible, 200mm/s is reached in 0.067s and covers 6.67mm. The remaining distance of the 15mm/s² acceleration will be covered in 0.0335s. This give the 3000mm/s² a total time of 0.1s against the 0.25s of the 1500mm/s². Even over a short distance of 26.67mm with the 1500mm/s² acceleration reaching 200mm/s at the halfway point the 3000mm/s² acceleration is only faster by 0.3s. So If the print has a lot of straight or near straight runs of 30mm or more the more powerful motors would have a minimal effect. If the print however had a lot of short runs of less than 26.67 then the more powerful motors would have an effect. However ringing is not your friend at high accelerations.

With the volumetric limit I have set for PETG giving a speed of 120mm/s on infill has the extruder reaching this speed in 0.08s and covering 4.8mm.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

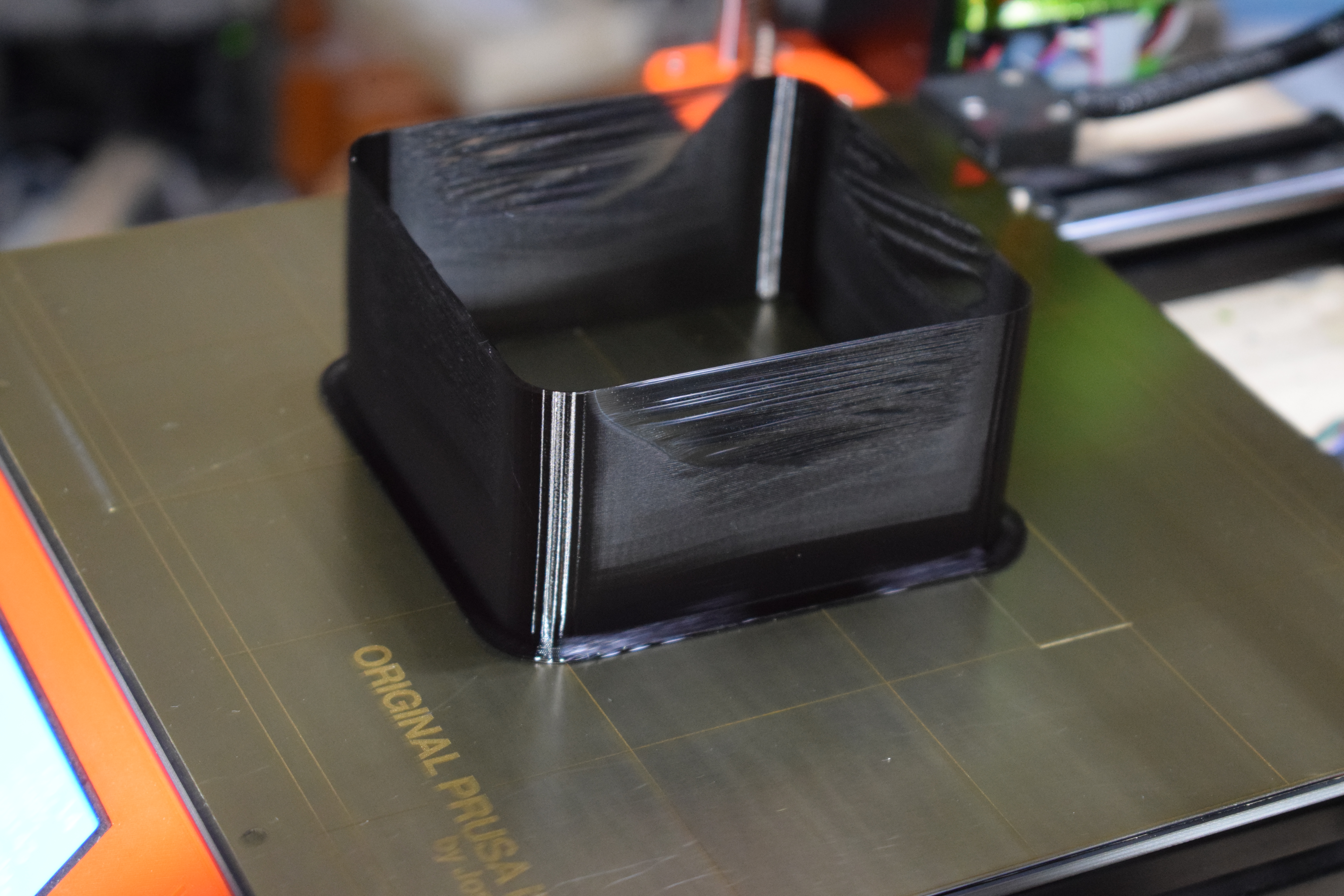

230°C K=45 With Sock

245°C K=60 Without Sock Left With Sock Right

Not much difference between with and a without sock.

The 230°C K=45 print gave a slight improvement in glossiness at the slower speeds but not enough to effect print speed selection and the extrusion problems again showed at the 175mm/s making 150mm/s the fastest practical speed.

The 245°C K=60 print brought the 125mm/s even glossier but still not to full gloss levels. 200mm/s this is better showing full extrusion and bonding and even very slight signs of gloss.

So in conclusion at 245°C K=60 with a sock if is possible to print PETG at the default PLA speed if you are prepared to put up with oozing. Comparing with the no sock 245°C K45 So I think I have found a PETG draught setting that matches the default Slic3r PLA results for speed. As without a sock it was only just starting to break down.

I'll do my Sunlu PLA+ speed tests tomorrow.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Not sure if higher torque motors would be worthwhile. In the PETG test I was only running at an acceleration of 800mm/s² and the default Slic3r acceleration for infill is 1500mm/s²

So in my tests the extruder travelled just 25mm with an acceleration of 800mm/s² to reach 200mm/s in 0.25s.

To reach 200mm/s at an acceleration of 1500mm/s² (Slic3r's default infill acceleration,) takes 0.13333s and covers 13.33mm

Assuming with upgraded motors 3000mm/s² is possible, 200mm/s is reached in 0.067s and covers 6.67mm. The remaining distance of the 15mm/s² acceleration will be covered in 0.0335s. This give the 3000mm/s² a total time of 0.1s against the 0.25s of the 1500mm/s². Even over a short distance of 26.67mm with the 1500mm/s² acceleration reaching 200mm/s at the halfway point the 3000mm/s² acceleration is only faster by 0.3s. So If the print has a lot of straight or near straight runs of 30mm or more the more powerful motors would have a minimal effect. If the print however had a lot of short runs of less than 26.67 then the more powerful motors would have an effect. However ringing is not your friend at high accelerations.

With the volumetric limit I have set for PETG giving a speed of 120mm/s on infill has the extruder reaching this speed in 0.08s and covering 4.8mm.

Regards,

Martin

You make a very compelling argument, I must say. How did you arrive at those times? Was it from reading the g-code? The reason I ask is that I presume that's what the slicer does when it comes up with its estimate for the print time, and yet the slicer almost always seems to underestimate the actual print time, sometimes wildly so. I've always wondered just how that could be, unless there's some leeway in how the gcode gets executed which allows for printing and/or other movements to take longer than they really should.

Re: Does someone want to know how fast they can print/extrude? look here

I’m getting similar speeds from skelestruder with a volcano. Works great on mk3 with bondtech and laser sensor.

Titan vs Skelestruder, I suggest a print-off 😀

Gcode from first post, how high can you go?

(You need to go to 'unlocked' feedrates ala MK2 in the Firmware first, no pitch change in motor movement means you are at the same speed, ergo the wall goes up at the same speed to the top )

Currently at 700% ( 350mm/s ) before the wall rips, although i haven't tried PETG yet.

Yes, I will give this a try when I get back into town. If you are tearing the filament, I don't see how to go any faster. But I should be able to match Titan no problem.

Ok, so I recompiled fw to remove limits and am maxing out print speed with no problems. However, I am not hearing much of a difference in motor pitch beyond 650%. So I don't think I'm really going over 325mm/s. But it prints super smooth with no tearing. This is on my MK3 with skelestruder, otherwise stock.

Re: Does someone want to know how fast they can print/extrude? look here

How did you arrive at those times? Was it from reading the g-code?

It was simple applied maths. I knew the acceleration, starting velocity and target velocity. Know these the time to change velocity can be calculated. Once the time taken is known the distance travelled can be found.

The formula used for constant acceleration

Acceleration A = a; Where a is acceleration

Velocity V at time t is given by V = at +b; where b is the velocity at time t=0

Distance S from the origin point at time t is given by S= ½at² + bt +c; where c is the distance from the origin at time 0

Simplifying we can call the stating point of a line the origin making c=0. As the velocity at the start of the line is 0 b=0 this gives:-

A=a;

V=at;

S= ½at²;

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Ok, so I recompiled fw to remove limits and am maxing out print speed with no problems. However, I am not hearing much of a difference in motor pitch beyond 650%. So I don't think I'm really going over 325mm/s. But it prints super smooth with no tearing. This is on my MK3 with skelestruder, otherwise stock.

Wow, that's great news. 😀 At the same time, it's mind blowing. Well, at least to me it's mind blowing.

As you can see above, Martin posted very nice photos of his printed output from running DevilHunter's test. Could you do the same so that we may properly admire your accomplishment?

Also, exactly which filament did you use?

Re: Does someone want to know how fast they can print/extrude? look here

Made some updated gcodes with the feedback here.

two for PLA, one with LA off and LA at K60

two for PETG, one with LA off and LA at K60

When i get one of my printers free i'll print the PETG LA one. (currently got some backorders)

btw, who can match the speed of this grandpa? (granted, that print looks like crap)

Re: Does someone want to know how fast they can print/extrude? look here

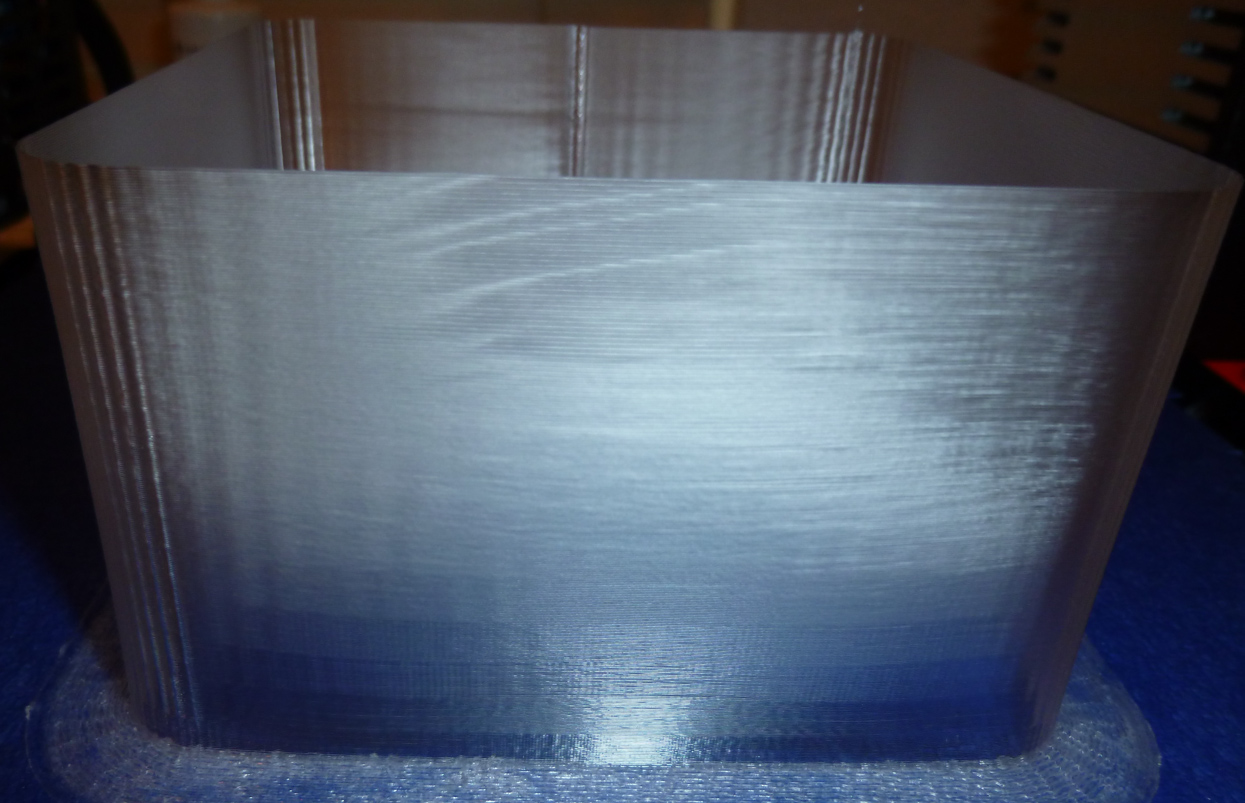

Today I tried an untinted PETG filament at K=50:

It goes to the limit of 300mm/sec without any catastrophic fails. I'd say it has probably performed the best at high speeds out of all the filaments I've tried so far.

Anyone know how to get past the 300mm/sec self-imposed speed limit?