What is the Smallest Thread That can be Reliably Printed?

I want to make a threaded standoff in the bottom of a box for mounting a circuit board. I want it to be a 4-40 thread but I'm afraid that something that small can't be printed very well. What's the smallest you've ever made and can I get some advice of how to go about it. Thanks.

Re: What is the Smallest Thread That can be Reliably Printed?

Try it! Experimenting is the best way to learn the limitations of your slicer and your printer.

Filament is cheap.

😀

Re: What is the Smallest Thread That can be Reliably Printed?

If I only HAD one, I would try it. I'm still waiting for it to ship. July I hope.

Until it comes I'm trying to learn all I can and design a few things I want to print. The lack of some kind of reference manual for this stuff makes learning a slow process. (Like how to create a thread for a 4-40 screw.)

Re: What is the Smallest Thread That can be Reliably Printed?

Get a copy of Autodesk Fusion 360 (free for non commercial use). It has built-in threading for holes and screws (be sure to select "model threads" so they'll export properly to STL)

If the threads end up being too small to print, consider printing a simple hole and use a tap to cut the threads. You might want to add an extra perimeter there to reinforce the hole (slic3r can use shapes to modify slicing settings in specific areas of a model without changing the whole thing)

Then there's the time honored "make a slot to put a nut in" technique…

Re: What is the Smallest Thread That can be Reliably Printed?

Fusion 360 was my first download. On about step #2 of the tutorial the sample design wouldn't load. Tried everything, even trashing F360 and reinstalling. Still no go, so I gave up on that and tried Tinkercad. So far it's doing everything I want (except easy threads I guess) so I'm stuck with it until I get more experience and need something more versatile.

I guess I'll just wait until I get my printer and try making 4-40 threads... but I know someone out there has been through this before with Tinker.

Thanks for your suggestion though.

Maybe there is a simpler way to do what I want. I'mm trying to mount a circuit board (0.062" thick) to a surface or a pedestal. Something that isn't permanent and allows me to remove the board if needed. Any ideas?

Re: What is the Smallest Thread That can be Reliably Printed?

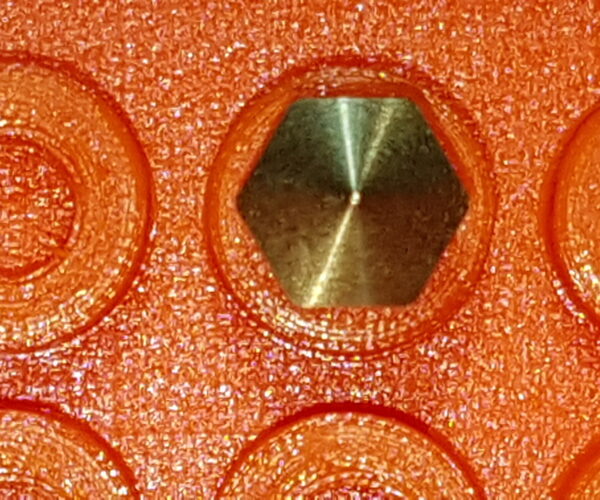

A M3 Screw and a nut is the smallest i could go down with a 0.40mm Nozzle on the MK2. Both worked great, but i tried about 10 times with different Slic3r settings.

Form 2 at work can reliably print M2 screws and M1.5 holes.

Re: What is the Smallest Thread That can be Reliably Printed?

Smallest I went is M5x40 with a 0.8mm pitch which came out pretty well in PLA. Be sure to print it with the longitudinal axis upright so your nozzle diameter isn't as limiting on the detail. You may want to add a brim to aid bed adhesion depending on the length/diameter ratio.

Re: What is the Smallest Thread That can be Reliably Printed?

I have successfully printed an M4.

Re: What is the Smallest Thread That can be Reliably Printed?

Appreciate the info & suggestions.

RE: What is the Smallest Thread That can be Reliably Printed?

Posted by: @eric-d14

"(be sure to select "model threads" so they'll export properly to STL)"

Thank you!! My Fusion 360 .stl exports were not showing threads in PrusaSlicer and I couldn't figure out why - Choosing 'Modeled' in the Edit Feature parameters in Fusion 360 solved this problem

RE: What is the Smallest Thread That can be Reliably Printed?

4-40 thread will print. I tested it last nigtht by downloading a nut and screw off McMaster Car.

--------------------

Chuck H

3D Printer Review Blog

RE: What is the Smallest Thread That can be Reliably Printed?

I want to make a threaded standoff in the bottom of a box for mounting a circuit board. I want it to be a 4-40 thread but I'm afraid that something that small can't be printed very well. What's the smallest you've ever made and can I get some advice of how to go about it. Thanks.

I do this all the time, but I cheat. 😉

Whenever I make something that holds a Raspberry Pi Zero, I'll make a standoff, but just put 1.2mm or so (radius) holes in them and then force-self-tap regular m2.5 screws. I've done this with both PLA and ABS and it actually works quite well and holds up over several removals and replacements.

RE: What is the Smallest Thread That can be Reliably Printed?

I often design parts with threads as small as M3 (3mm) as long as the threaded holes is printed in vertical direction. Material is PETG and my nozzle is 0.4mm in MK3S - layer height is 0.15 for most parts.

Another method is threading the holes after with a tap (as suggested in other posts). I use this method when holes is printed in non vertical direction. Make the hole smaller to get material to cut the thread.

Print modifiers can be used around threaded holes to make them stronger with more perimeters and denser infill.

Try it out and you will soon find your way.

On the SL1 the threads can be very small and in any direction - M2 is no problem... 😉

Have a look at my models on Printables.com 😉

RE: What is the Smallest Thread That can be Reliably Printed?

4-40 thread will print. I tested it last nigtht by downloading a nut and screw off McMaster Car.

I tried again and failed.

--------------------

Chuck H

3D Printer Review Blog

RE: What is the Smallest Thread That can be Reliably Printed?

0.1mm is the smallest nozzle I have ever printed with on the MK3. I think it can be used to print screws with 1 to 2 mm diameter.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: What is the Smallest Thread That can be Reliably Printed?

Whenever I make something that holds a Raspberry Pi Zero, I'll make a standoff, but just put 1.2mm or so (radius) holes in them and then force-self-tap regular m2.5 screws. I've done this with both PLA and ABS and it actually works quite well and holds up over several removals and replacements.

I'm inclined to agree. Early on, I got a bit obsessed with printable threads and have gotten pretty good with Fusion 360's toolset to create them. I finally realized I can waste a lot of time and effort on smaller threads and probably not achieve better results than hand-threading them.

Stefan did his usual excessive testing of threading method comparisons on his YouTube channel in 2019. All of the bare plastic methods perform comparably. He mentions some screws that are specifically meant for self-threading in plastic. Also, don't forget the tendency of PLA to soften under pressure over time.

RE: What is the Smallest Thread That can be Reliably Printed?

I use self-threading/wood screws too and they are much easier to model holes for and properly has better holding strength (@bobstro reference to Stefan YouTube test). If rare/no disassembly are the case they are my first choice.

Have a look at my models on Printables.com 😉

RE: What is the Smallest Thread That can be Reliably Printed?

I lowered to 0.2mm nozzle and succeded. Not very strong. I will try PC blend.

--------------------

Chuck H

3D Printer Review Blog

RE: What is the Smallest Thread That can be Reliably Printed?

I do not print small internal threads M1 to M3 directly, only the core hole. Afterwards I cut the thread with a hand tapper (nr.1).

Usually, however, I prefer to use threaded inserts for soft materials.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: What is the Smallest Thread That can be Reliably Printed?

I find that printing with PETG when using 3mm screws, I don't need to do anything except create an 3mm hole, the PETG printing tolerance leaves enough exposed material for the threads to grip so the screw just screws itself in cutting it's own thread.

Maybe a properly formed thread would have a bit more strength, but this method is surprisingly strong, a 6mm long x 3mm diameter hole, with a screw in it will break the plastic out of the back before it strips any thread!, Oh and make sure you use at least 3 perimeters for the 3mm hole and learn to print PETG with very little cooling so that you get really strong layer adhesion. I run my part cooling fan just above stall speed, I can't go any lower without it stopping all together.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.