Rotation Visualizer Failure

I printed a rotation visualizer 4 weeks ago in MatterHackers Pro PLA and fixed it to a Rare Earth magnet with CA glue with no surface preparation. Things went fine until today, when it failed with annoying consequences:

Getting the magnet off of the axle of the extruder stepper motor was no picnic. It refused being grasped by pliers, vice-grips, or any “grabber” type tools, because of the miniscule clearance above the body of the stepper motor. I eventually succeeded by sticking it to 3M VHB double-sided adhesive (back of a GoPro mounting bracket).

The glue bond may have failed due to lack of surface prep. I am now running both the metal and plastic parts over a coarse file prior to gluing.

After gluing on one magnet, I re-installed the part and realized it was warped and rubbing against the body of the extruder stepper motor.

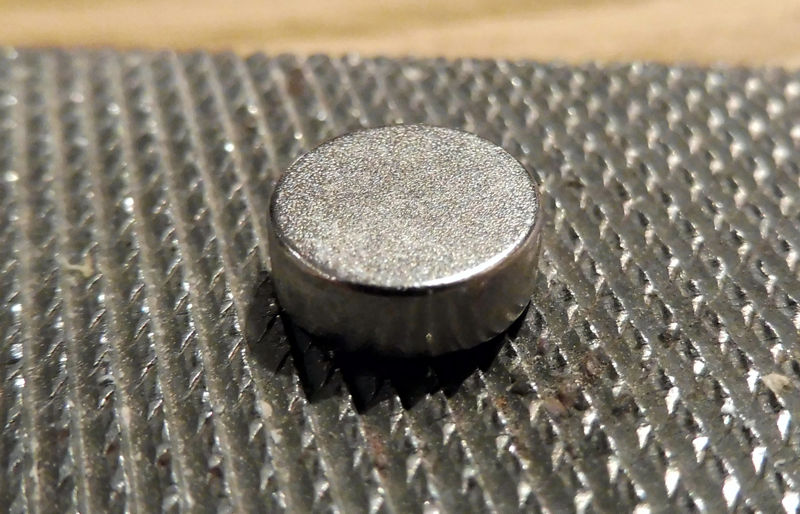

The warping can be seen in this picture, as well as the two magnets – both CA-glued – which I am now using to raise the visualizer away from the extruder stepper motor.

-- Clint Goss

Re: Rotation Visualizer Failure

Easiest way to get the magnet off is with another magnet.

Also, when I get warps like that on flat object, just put it in boiling water.. And then press it down on a flat surface...

Re: Rotation Visualizer Failure

Easiest way to get the magnet off is with another magnet.

Also, when I get warps like that.. Put it in boiling water.. And then press it down on a flat surface...

Re: Rotation Visualizer Failure

.. another magnet.

.. boiling water.. And then press it down on a flat surface...

Thank you!! ... I'm a newbie, and I just don't think of these things ...

I'm wondering ... Is it really that hot in the area in front of the extruder stepper motor - enough to warp PLA?? I wouldn't have thought ...

-- Clint Goss

Re: Rotation Visualizer Failure

.. another magnet.

.. boiling water.. And then press it down on a flat surface...

Thank you!! ... I'm a newbie, and I just don't think of these things ...

I'm wondering ... Is it really that hot in the area in front of the extruder stepper motor - enough to warp PLA?? I wouldn't have thought ...

Its almost certainly not warped in the true sense.. The layer didn't adhere to the bed, so as the top layers cooled, it pulled the bottom layers up in a warp.

You need to tweek your setup such that the first layer sticks and needs to be cracked off by flexing the bed.. If its not fully stuck, you will see this warp (curl) on everything you print.

Re: Rotation Visualizer Failure

I'm wondering ... Is it really that hot in the area in front of the extruder stepper motor - enough to warp PLA?? I wouldn't have thought ...

Its almost certainly not warped in the true sense.. The layer didn't adhere to the bed, so as the top layers cooled, it pulled the bottom layers up in a warp.

You need to tweek your setup such that the first layer sticks and needs to be cracked off by flexing the bed.. If its not fully stuck, you will see this warp (curl) on everything you print.

The top surface isn't flat. It's *ACTUALLY* warped. I'm not sure what would cause this.

Was it warped before you glued the magnets?

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Rotation Visualizer Failure

I'm wondering ... Is it really that hot in the area in front of the extruder stepper motor - enough to warp PLA?? I wouldn't have thought ...

Its almost certainly not warped in the true sense.. The layer didn't adhere to the bed, so as the top layers cooled, it pulled the bottom layers up in a warp.

You need to tweek your setup such that the first layer sticks and needs to be cracked off by flexing the bed.. If its not fully stuck, you will see this warp (curl) on everything you print.

The top surface isn't flat. It's *ACTUALLY* warped. I'm not sure what would cause this.

Was it warped before you glued the magnets?

I am not sure I understand what you mean by "warped".. To me it just looks like its contracted and lifted the arms of the bed as it cooled.

Re: Rotation Visualizer Failure

Was it warped before you glued the magnets?

No! It was dead flat when I printed it and when I glued on the magnets.

It warped during use, sitting on the extruder stepper motor. Is this area really that hot? Conducted heat through the shaft of the motor and the magnets? Ambient heat wafting up from the nozzle area??

-- Clint Goss

Re: Rotation Visualizer Failure

Yes, I think it does get hot enough to warp PLA. I'm pretty sure I read that the firmware currently nearing release (I hope! ) will actually reduce the extruder stepper temperature. I have a mk3 and a mk2s and the mk3 extruder stepper gets much hotter. Even if you don't have any fancy IR camera or non-contact thermometer you can trust, just try a print of PLA with a 60C bed temp and touch each (bed and extruder stepper) by hand for comparison - just briefly though of course :).

Re: Rotation Visualizer Failure

Yes the extruder motor can get so hot that it will deform PLA rotary indicators.

Use ABS or maybe PET. (or any material that can withstand temperatures above 60°-70°

New Firmware currently release Candidate RC2 will potentialy lower the extruder Temps but since those are not fully released yet there is little information on how much that will change the Temps.

Re: Rotation Visualizer Failure

Was it warped before you glued the magnets?

No! It was dead flat when I printed it and when I glued on the magnets.

It warped during use, sitting on the extruder stepper motor. Is this area really that hot? Conducted heat through the shaft of the motor and the magnets? Ambient heat wafting up from the nozzle area??

Ahhhh.. I see now.. PLA goes soft at about 60-80 degrees, so its quite conceivable that the motor gets hot enough to make the PLA soft and cause this kind of warp.

Re: Rotation Visualizer Failure

No! It was dead flat when I printed it and when I glued on the magnets.

It warped during use, sitting on the extruder stepper motor. Is this area really that hot? Conducted heat through the shaft of the motor and the magnets? Ambient heat wafting up from the nozzle area??

Ahhhh.. I see now.. PLA goes soft at about 60-80 degrees, so its quite conceivable that the motor gets hot enough to make the PLA soft and cause this kind of warp.

@clint.g

Try printing it in ABS, if you have any. ABS can be a bit of a challenge to get to do what you want at first though.

Another option would be to get a HTPLA (High Temp PLA) and anneal it. (I'm specifically thinking 3D850, 3D870, based filaments, or MatterHackers Raptor PLA.

I am not experienced with PETG so I can't give advise on it. 🙁

I would assume the warp is caused by the heat from the motor. The motors frequently run in the neighborhood of 60c, which is hot enough to potentially cause issues with PLA, and with the "metal on metal" connection. (the magnets) the "center" of the part will get MUCH hotter than the "ends".

@jweaver

What i meant by that, was when things "warp" on the print sheet, the corners will lift up, and it creates a really weird effect during the print, that results in a "flat top" and "curved" bottom. VERY hard to explain, but essentially, the "warp" cuts into the layers above it.

so if you were to print a 5x10x5 "rectangle" that one side warped. you would end up with a perfectly flat "top" surface all the way across it, however one side, could in theory have a point like a chisel.

I've never seen the "top surface" have relevant warping, outside of "curling" on corners/overhangs.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Rotation Visualizer Failure

I always print these parts with Prusa Orange PETG... no issues so far with post-installation warping.

Re: Rotation Visualizer Failure

I am not experienced with PETG so I can't give advise on it. 🙁

I might be able to help!

PETG doesn't quite have the temperature resistance of ABS, but it can generally handle up to around 80°C. I think that'll be fine for the MK3's extruder motor, but I haven't measured its operating temperature yet. In my experience, PETG prints consistently well with no warping and no unpleasant odors.

The main downside with PETG is that it can be a bit stringy. Using more aggressive retraction settings can help mitigate that a bit, but it's not going to go away entirely. Additionally, it's also hygroscopic. Storing it in a dry box is a must, and it may be necessary to dry it in an oven if issues arise.

colorFabb NGEN, XT, and HT are also copolyesters and should behave somewhat similarly, glass transition temperatures aside.

Putting down glue stick or Windex as a separation layer is a must to prevent overadhesion (and apparently blue painter's tape works very well, though I haven't tried it myself). Raising the Z height by a bit can help improve the first layer as well.