PETG First Layer Settings using Overture PETG

Opinions please from anyone using Overture brand PETG. I've printed my first parts using Overture brand red and black PETG on the smooth PEI sheet. I'm using the generic PETG settings in PrusaSlicr which uses a temp of 230. The parts printed fine and look excellent except the first layer of most parts has a very smooth finish on one portion and visible lines on the rest that you can feel when you run a fingernail across them. I increased the first layer Z value and that resulted in an almost all smooth first layer, but the part had a fair amount of elephant's foot. Should I go back to my original first layer Z value and increase the temperature some, perhaps to 240 or 250? Would this cause the first layer to "flow" together a bit more?

RE: PETG First Layer Settings using Overture PETG

I have used the Prusament PETG setting with great success.

Overture Clear PETG came with a bed adhesion surface that is adhesive. I plan to try it as soon as some releases a steel sheet to use it on.

--------------------

Chuck H

3D Printer Review Blog

RE: PETG First Layer Settings using Overture PETG

I frequently print with Overture PETG. 1st layer thickness is indeed dependent on getting Z just right. That you'll have to play with because it can be idiosyncratic for your printer / plate combination. As you have noted too far above plate creates separated lines. Too low and you get continuous layer but some elephant foot. Which is pretty much like any other filament.

My usual temps with Overture PETG on E3D V6 with 0.4 brass nozzle that get reliably goot results on a texture PEI are...

Extruder 1st layer 255 Other layers 260

Bed 1st layer 85 other layers 90

Yes, that is a bit hotter than you are using.

RE: PETG First Layer Settings using Overture PETG

If you have not done the LIFE Z MY WAY process for getting Z correct, definitely do that and allow MESH leveling to do more than just 9 points.

Search this forum for the LIFE Z MY Way thread and files. Yes, LIVE is intentionally misspelled because thread title is that way.

RE: PETG First Layer Settings using Overture PETG

"Elephants foot" is normal for the first layer to insure good adhesion to the bed with a nice squish. If you find that troubling you can change slicer settings to help that. If printing at 0.2mm, just adjust the first layer in your slicer to 0.15mm so even with a squish it will not have "Elephant foot". Just realize you will not have as wide a bond area with the bed so do a test print to see if the adhesion is strong enough for the print you are doing. If the first layer is very small on the object you are printing that might not work out well, but if you get a good bond it should be fine. You may need to adjust Z height for first layer to get this right, but with a bit of testing and adjusting you can set as a preset for Steel sheet 2 or Texure sheet 2 and use it when it matters to you.

RE: PETG First Layer Settings using Overture PETG

Thanks for the inputs Folks. I'm going to play around with temperature and speed, and bed temp and see what happens.

RE: PETG First Layer Settings using Overture PETG

@guy-k2

Thanks much. I was having a hair-pulling problem with an ornamental hinge that had a great deal of support material under it. Although your settings seemed counter-intuitive, I thought 'what do I have to lose' (trick question, answer was nothing) and tried them. Success. I got a print. The only downside was that the support material fused quite tightly to the model and was a real cow to get off. I'm wondering if the contact Z distance (set to .1mm by default) might be twiddle-able.

RE: PETG First Layer Settings using Overture PETG

I tend to use contact z of 0.3 mm for my supports in PETG. Try a bigger spacing that 0.1 mm if you get too much fusion

RE: PETG First Layer Settings using Overture PETG

Tried .3 mm for contact z. While I wouldn't say getting the support material off was easy, it was certainly a sight easier than the .1 mm setting. For anyone reading this, I'm using Overture PETG on a Prusa Mark3s and Slic3R. Settings are default save for these:

Under Support Material

Contact Z distance = .3mm

Under Speed

Infill=50mm/s

Solid infill = 50mm/s

Support = 40 mm/s

Under Print Settings

Skirt and Brim

Brim width = 3mm

Under Filament settings

Extruder

first layer = 255C other layers = 260C

Bed

first layer = 85C other layers = 90C

Hope this helps any other newbies out there. And thanks so much again, guy-k2, for your help. You saved me much trouble.

RE: PETG First Layer Settings using Overture PETG

Interesting to read through this. I snagged some Overture PETG recently and had some trouble initially. I have a Prusa Mini+ and was printing the Prusa Mini Stand (really long 18-21 hour prints for the main legs), but had trouble with exceedingly good bed adhesion (damaged the PEI bed when I removed the cooled part) and wrinkling/warping in the first 20 layers or so due to too much heat. That was with the standard 250 print temp and 90 bed temp. I also had pretty minor stringing. I dialed things back to 245 on the print and 75 on the bed. It still sticks almost too well, but can be removed without damaging the bed after it has cooled. The stringing virtually disappeared. I may try dialing the bed temp back even further to make the clean up of support/raft material easier and minimize the pressure needed to remove large prints. Are you guys having this crazy bed adhesion issue as well?

RE:

I know this is an old thread but it still helped me. Thank you all for your information.

This is the only filament* I have had so many problems with. I have spent hours trying to figure out a reasonable print temperature and am still having problems. Right now I am printing at a temperature of about 260 degrees Celsius. If I print at a lower temperature, the whole print doesn't work. I also had to lower the print bed temperature because otherwise I couldn't remove the prints without damaging my printing bed.

FYI if this helps: I copied the prusa slicer profile for "PrusaPETG" and edited the temperature settings.

This was my first and last time buying this filament - never again.0

*(compared the other PLA or PETG filaments I have)

RE: PETG First Layer Settings using Overture PETG

I've used Overture brand PETg and it's always printed just fine on the MK3S using the default 'generic PETg' profile. 230/240 on the nozzle, IIRC, and 85 on the plate.

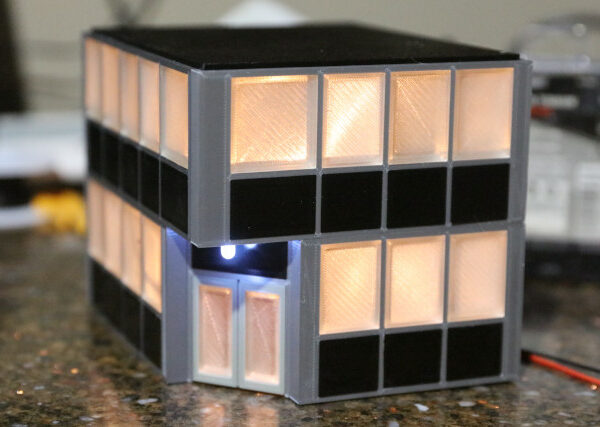

I've used other colors too, but specifically I got Overture PETg in so-called transparent when my spool of RepRappers so-called transparent ran out during the height of the pandemic and I could not find another in stock. I did not change anything, just unloaded the tag end of the RepRappers spool and loaded in the Overture spool and continued the project.

I use it mostly for windows for model railroad buildings and it's always printed very well on the MK3S.

RE: PETG First Layer Settings using Overture PETG

Most of what I have printed so far has been Overture PETG and it prints fine for the most part. The spool of red that I opened the other day has been acting a little weird, but it's printing mostly OK too.

RE: PETG First Layer Settings using Overture PETG

Thank you for your feedback. I don't know if it just an issue with my spool. It's Overture PETG transparent. I did the same print with PrusamentPETG and this worked perfectly (I only changed the print profile to PrusaPETG).

May I ask: What kind of preset in prusaslicer did you use? PrusaPETG or the GenericPETG and then adjusted the temperature? So I could give it a try. Thank you in advance for your inputs.

RE: PETG First Layer Settings using Overture PETG

I am using the generic PETG settings and have not messed with the temperatures at all. The only thing I have done is for a few spools that I was using to make printer parts from, I went to the trouble of calibrating the extrusion multiplier for those individual spools because the designer of my second printer said to do so. For other prints I haven't bothered. I printed all of the parts for my second printer from Overture PETG in "starry blue" and black (for the extruder parts).

RE: PETG First Layer Settings using Overture PETG

I pretty much exclusively use either the Prusament PETG and Generic PETG setting depending on the filament.

I am using the generic PETG settings and have not messed with the temperatures at all. The only thing I have done is for a few spools that I was using to make printer parts from, I went to the trouble of calibrating the extrusion multiplier for those individual spools because the designer of my second printer said to do so. For other prints I haven't bothered. I printed all of the parts for my second printer from Overture PETG in "starry blue" and black (for the extruder parts).

--------------------

Chuck H

3D Printer Review Blog

RE: PETG First Layer Settings using Overture PETG

Thank you very much for your information, good to know. I don't know if I just have a problem with that spool. It is the first spool that doesn't print with the generic profile (unfortunately it is also the first spool from Overture so I have no other experience with this vendor).

I will dry the spool (shouldn't be moist, I heared no cracking etc.) but it can't hurt. Then I will try it again with the generic settings before I tweak anything with the temperature.

RE: PETG First Layer Settings using Overture PETG

Which print sheet are you using? The smooth one will need a release agent like glue stick or Layerneer or similar.

I print a fair amount or Overture PETG using the generic profile and generally at around 230-235 first layer and 225-230 for additional layers but, it seems to vary by color. I have a roll of magenta that needs to print at around 210-215 and half speed or slower for best results.

I’m using either the satin or the textured sheets. I don’t own a smooth sheet. I generally have good results with the Overture PETG. Occasionally it takes some experimenting to tune in a particular roll. You could try printing one of the temperature tower models that are out there to help with tuning in your settings.

Cheers

RE: PETG First Layer Settings using Overture PETG

@RandyM9: Thank you for your input.

I use the textured steal sheet and never had problems with eSun PETG or Prusament PETG (I printed many spools on it).

I printed many of the temp tower (230 - 270) and couldn't find a good temperature. A) not hot enough or B) it was so hot, that I couldn't really remove it from the print bed and it had some burned places when printing over 265 on the print (just to hot I guess). The first time I had a "ok" print was starting with 260 degrees, but then it was really hard to remove it from my print bed. I also re-calibrated my Z-offset (even if it was working before with the other PETG filaments).

This is why I thought I will dry the spool just to be sure. Then I will start over again with the standard generic PETG profile (at the moment I use the PrusaPETG profile).

For me it is good to know, that in general many people have achieved good results with this vendor, sometimes needed fine tuning with higher or lower temperature that is usual. I think I have all the information for the moment for my troubleshooting, thank you very much.

I should be able to dry the spool in the next 1-2 week(s) and can start the testing (as soon as my print queue is done, I have some parts that need to be printed first). A soon as I have a (good) result I will publish my findings that may help later somebody else with the same filament.

Wish you all a great weekend.

RE:

Thank you all for the input. I figured it out and it works fine for me with the standard (Generic) Profile. I changed to a 0.4mm nozzle and also dried the filament.

I checked the "old" 0.6mm nozzle and I think it had a deformation (filament slightly curling). Interesting is, that it still worked for eSun and Prusa PETG and other PLA, but Overture PETG was not possible to print with this nozzle. This was the reason why I didn't have the nozzle on focus.

Unfortunately I can't edit my first post - otherwise I would write there directly the reason, so people don't have to read all the thread.