New user - Question about cracks in smooth plate

Hi all,

Got my first MK3s+ in mid December. Have been having a blast with it! However, about a week ago I noticed a crack in my smooth plate. I know these plates are considered wear items, but after reading about others' experiences I think this might be a bit premature.

I only clean it with ISO and sometimes Windex. A couple of weeks ago when I first started printing with PETG I was having some adhesion issues and did wipe it down with acetone, but that was the one and only time I used that. And it didn't help, my adhesion issues were due to my Live Z needing some additional adjustment. Plate is also cleaned occasionally with hot water and dish soap, but now that I have the printer properly adjusted that is rarely necessary any longer.

I don't use any tools to remove prints, with the exception of a razor blade if I am printing very small parts that don't pop off when I bend the sheet.

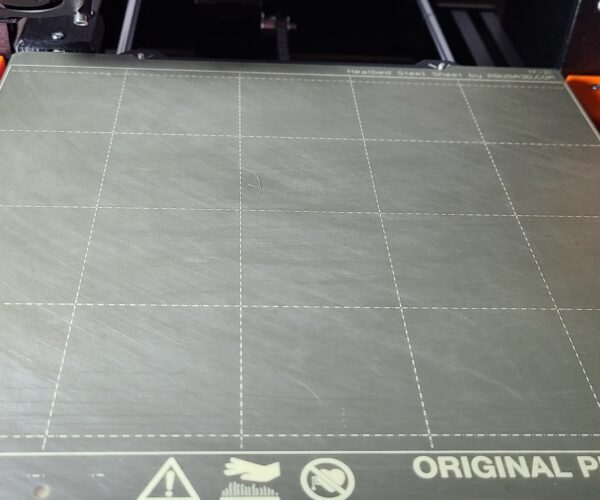

Attaching a photo of the cracks. The shorter crack is 'worse' than the longer one, as it looks like the PEI is actually starting to curl / pull up. The other side of the sheet is fine. Please excuse the swirl marks, I read about wet sanding the sheet recently so I hit it with some 320 grit sandpaper to try to smooth out the crack, as it does cause a blemish in printed parts.

Is there anything I could have done to cause this? Should I ping Prusa support about this? I checked the web site and of course with my luck the smooth sheets are also out of stock now.

Thoughts?

RE: New user - Question about cracks in smooth plate

Acetone could have played a part in that. It has never happened to me, but I read of cases.

--------------------

Chuck H

3D Printer Review Blog

RE: New user - Question about cracks in smooth plate

Hi all,

Got my first MK3s+ in mid December. Have been having a blast with it! However, about a week ago I noticed a crack in my smooth plate. I know these plates are considered wear items, but after reading about others' experiences I think this might be a bit premature.

I only clean it with ISO and sometimes Windex. A couple of weeks ago when I first started printing with PETG I was having some adhesion issues and did wipe it down with acetone, but that was the one and only time I used that. And it didn't help, my adhesion issues were due to my Live Z needing some additional adjustment. Plate is also cleaned occasionally with hot water and dish soap, but now that I have the printer properly adjusted that is rarely necessary any longer.

I don't use any tools to remove prints, with the exception of a razor blade if I am printing very small parts that don't pop off when I bend the sheet.

Attaching a photo of the cracks. The shorter crack is 'worse' than the longer one, as it looks like the PEI is actually starting to curl / pull up. The other side of the sheet is fine. Please excuse the swirl marks, I read about wet sanding the sheet recently so I hit it with some 320 grit sandpaper to try to smooth out the crack, as it does cause a blemish in printed parts.

Is there anything I could have done to cause this? Should I ping Prusa support about this? I checked the web site and of course with my luck the smooth sheets are also out of stock now.

Thoughts?

I

I would avoid acetone or similar materials and not use them to clean the print bed, as the PEI quickly becomes brittle and fragile. Likewise, it is important to remove the printed parts only from the printing plate that has cooled to room temperature. I would avoid metal spatulas and rather use plastic spatulas. To treat the surface, I always use 1000 grit wet sandpaper and clean sufficiently with warm water afterwards.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: New user - Question about cracks in smooth plate

Thanks 🙂 I only used acetone because I read from Prusa that it could be used occasionally on the smooth sheet if there were adhesion issues. I also have a textured plate and know I can't use it on that ever. And since it didn't really help with my adhesion on the smooth plate anyway, I don't plan on using it again.

RE: New user - Question about cracks in smooth plate

@twoballscrewball

I do use acetone, but it is only a last resort if adhesion is failing and nothing else works.

I use:

- IPA

- Soap and water

- Soap, water, not scratch scrubber

- Sanding with 1000-3000 grit sandpaper. Performed in a circular motion to increase adhesion like buffing.

- Acetone - quick poor and remove. This I only do if I considering disposing of the sheet.

I start with number one and work my way now. I never use 5 unless I am at the end of the sheet's life. I have never damaged a sheet with acetone, but it is a quick pour and remove to reset the surface. A few seconds of contact.

--------------------

Chuck H

3D Printer Review Blog

RE: New user - Question about cracks in smooth plate

Update on this post. I figured this was my fault and chalked it up to new used error, so I bit the bullet and ordered some replacement PEI from Prusa, as well as another smooth sheet in case I screwed up the PEI replacement 🙂 . I went through the documented process of freezing the plate and then removing the PEI. When I did that, the green surface under the PEI also came completely off of the sheet on one side, and partially on the other. I contacted Prusa when this happened to ask for advice, and they decided the sheet was defective and sent me a new one. So now I have 2 smooth sheets and two unused PEI stickers. Should be good for a while now 🙂

Very pleased overall with Prusa support.

RE: New user - Question about cracks in smooth plate

Good to see they send you a new one. It would have been so easy for them to say it is a consumable part and be done with it.