Let there be light and a front row seat to the nozzle show...

I spent a couple hours making my first mod to my MK3S today.

.

I have great intentions of finishing this concept off with designing a real 3D printed part instead of that high temp glue gun 'blob' and then post a whole 'How-To' forum topic, but now that it is working, I bet that I will never get around to that and then I thought that others could take it from here if they wish so hence this forum posting.

.

I used a section of 7 of the 28 leds in these $3 12v LED strips https://www.amazon.com/gp/product/B071PFC1H2 I just cut the strip off after 7 leds with some scissors and then figured out where I had to solder the tracks back together, at my scissor cut, to make them work again (but on 3V now).

.

The 7 LED section is rated for 3V but I am supplying them with the chopped 5V supply to the nozzle fan. I print PETG and it is running at 50% duty cycle at 30 hz most of the time, so the LEDS shouldn't be too overloaded. They have been running fine for about 5 hrs now. Their aluminum backplate gets to ~60 degC so I am not too worried (they are cheap to replace 😉 )

.

The 7 LED section at 5v 50% duty cycle only draws about an average of 100 ma so I am taking a chance that the pwm driver for the fan is up for the extra load 🤔

.

It is cool 😎, there are occasional blips of 100% duty cycle 5 volts on the fan and the LEDs brighten up obediently:)

.

Also, the light comes on and off with the nozzle fan so I never have to remember to turn it on or off.

.

Only current issue is that the nozzle fan does not seem to come on until a few minutes after the print starts, anyone with an idea how to get the fan to come on earlier (even at a low duty cycle would work)?

.

So here you go:

Best Answer by DaleKramer:

Thanks Rick,

.

You got me thinking about the issue (watch out when I think 😉 ) and I came up with a solution I have tried out and it seems to answer my issue.

.

I ended up finding this great resource for gcodes: https://help.prusa3d.com/en/article/prusa-specific-g-codes_112173

.

After finding that, I simply added a line to my 'Printer settings' > 'Start G-code' section to do what I pondered in my 1st post...

.

I inserted a line to turn on the fan at its minimum duty cycle in between nozzle and bed temperature waiting times like so:

.

- M109 S[first_layer_temperature] ; wait for extruder temp

- M106 S76.5 ; DALE added for fan and light on at lowest duty cycle 30%

- M190 S[first_layer_bed_temperature] ; wait for bed temp

.

My reasoning there is that since I always have my print head at Z 210.0mm at the start of a print (by having edited the 'End G-code line :

{if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+300, max_print_height)}{endif} ; Move print head up ), I would like the light to turn on just as the print head starts moving down to complete its home and mesh bed leveling. This gives me time to inspect/clean the nozzle during its long move down of 210mm before it begins the bed leveling...

RE: Let there be light and a front row seat to the nozzle show...

AND you can tell when your print is finished if you are too far away to hear it, but you can still see it, since the light goes out when it is finished the print job.

.

This should be useful when I get the 17 MK3S+'s I ordered with the Black Friday deals for my printer farm 😉

RE: Let there be light and a front row seat to the nozzle show...

Typically the part cooling fan doesn’t run during the first layer to help adhesion. Look in the cooling section of your slicer settings. You can change it there.

RE: Let there be light and a front row seat to the nozzle show...

Thanks Rick,

.

You got me thinking about the issue (watch out when I think 😉 ) and I came up with a solution I have tried out and it seems to answer my issue.

.

I ended up finding this great resource for gcodes: https://help.prusa3d.com/en/article/prusa-specific-g-codes_112173

.

After finding that, I simply added a line to my 'Printer settings' > 'Start G-code' section to do what I pondered in my 1st post...

.

I inserted a line to turn on the fan at its minimum duty cycle in between nozzle and bed temperature waiting times like so:

.

- M109 S[first_layer_temperature] ; wait for extruder temp

- M106 S76.5 ; DALE added for fan and light on at lowest duty cycle 30%

- M190 S[first_layer_bed_temperature] ; wait for bed temp

.

My reasoning there is that since I always have my print head at Z 210.0mm at the start of a print (by having edited the 'End G-code line :

{if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+300, max_print_height)}{endif} ; Move print head up ), I would like the light to turn on just as the print head starts moving down to complete its home and mesh bed leveling. This gives me time to inspect/clean the nozzle during its long move down of 210mm before it begins the bed leveling...

RE: Let there be light and a front row seat to the nozzle show...

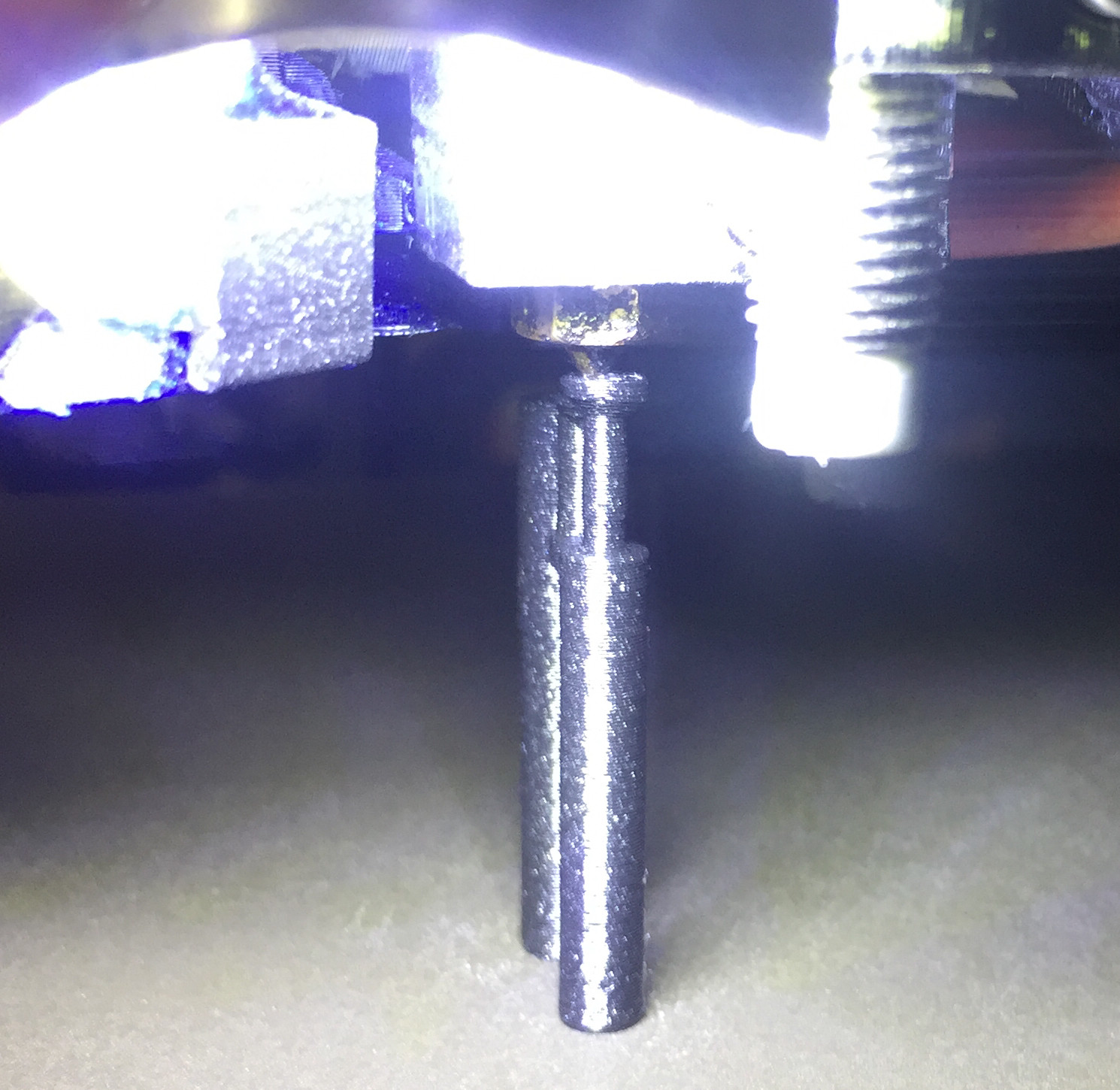

And here is where my mod really shines (forgive the pun).

.

A closeup view of the nozzle during printing which really helped me nail this part design and printing parameters since I could see what was happening when the print was messing up making that knob on top of the near pillar. (I simply added a helping hand from the nearby 2nd pillar to keep the near pillar steady as the wider knob was formed):