I am so angry. This printer has such a high fail rate.

Printer: Original i3 MK3

Slicer: PrusaSlicer

Filament used: Any Prusament (although it's currently Prusa Jet Black)

Printer setup: standard (never changed)

Print setup: PLA, nozzle 215, bed 60 speed <100% (as low as 64), 79F ambient, AC + fan

Attach files: ANY file taller than 60mm

RE: I am so angry. This printer has such a high fail rate.

Drag and drop images into the text box - the box changes color when you can drop safely.

Generally - without seeing pictures, the print sheet has fingerprints on it. One finger print will ruin a print by causing it to lift off the bed. PLA and finger oil are not compatible.

Keeping the bed completely and absolutely clean is a hard lesson for some people to learn. While alcohol can work, if you do not use enough alcohol and a fresh rag every time, you are just moving the oil around rather than picking it up off the bed.

Washing the print sheet in soap and hot water at a sink is the best solution to parts falling off the sheet. Scrub with a fresh paper towel using a few drops of a good PLAIN detergent, rinse in hot water until the water beads and sheets of the PEI surface. Dry by dabbing up the few remaining water drops with another fresh paper towel. And handle the sheet by the edges only. NEVER touch the print surface with hands, fingers, palms, ever.

First off, yes, my printer is calibrated. It's almost dead flat. It's frighteningly flat. I ran a dial indicator across it. If you don't know what that means, then I can virtually assure you that my bed is flatter than yours. (please forgive me, I'm not trying to be condescending - it's just an emphatic way of saying that my bed is as flat as it's gonna get) There is no warpage. Adhesion is excellent. I wash regularly with soap and water, and rubbing alcohol.

Well, if you are using rubbing alcohol you do not know what I mean by use soap and water. Again, keeping the bed clean is hard for some.

RE: I am so angry. This printer has such a high fail rate.

What bed are you using, the pei or powder coated?

Most important for printing is:

1. Clean bed, use dish soap a few times.

2. First layer calibration needs to be 100%.

Both settings are for getting a good model and a good sticking to the bed.

Then the slicer settings are only settings that should work if everything is OK, hardware and filament and temperature, and you need to adjust id printing fails. This takes time to learn, keep reading forum. And a 3d printer is not made to load model and print and I am ready to get a good print, this will not happen for a long time, and this is for every 3d printer.

Pla will stick not good to a powder coated sheet, use the pei sheet, is a lot easier.

Petg will stick to much to a pei sheet , use glas cleaner to spray on the bed, so it does not stick to much.

Petg on a powder coated bed works good, clean with dish soap, then a few times with alcohol.

If a print does not stick to a bed,

first layer hotter,

first layer slower,

make bed hotter for the whole print, like pla 60 to 70,

use glue stick,

try different filament,

use a big brim attach to model,

small foot print(to the bed) or a big flat model use a brim attach to model, and glue stick.

Let bed and printer heat up, like I have a encloser, I let the encloser heat up, then I start printing.

And remember you need to learn, and this takes time, and keep reading forum for tips and get the latest (problems)info about your printer.

RE: I am so angry. This printer has such a high fail rate.

It's not an adhesion issue. I can hear the parts come off the bed. It sounds like bullets hitting metal targets.

Perfect prints until it gets to about 60%. Then, the head plunges downward into the part. Literally plows right in. There are perfect circular (albeit blobby) divots in these parts. I have about a dozen different parts, all exhibiting the same behavior. Some of them are just perfect witness marks, bearing the shape of the nozzle.

Again, it's 100% not an adhesion issue.

RE: I am so angry. This printer has such a high fail rate.

Hi...

Is your live Z value greater than 1mm?

if it is, then you might want to consider raising your Pinda sensor half a turn, or one full turn,

the screw thread has a 1mm pitch so one turn, or one click will move the pinda up one milimetre.

then you must re adjust your live Z...

this will have the effect of raising your Pinda, relative to your nozzle, and if the Pinda is contacting with your print, then the pinda being a milimeter higher will make this less likely.

when the problem occurs, what does the display say?

after a failure, is the bottom of your model as smooth and flat as your build plate? or is there evidence of lifting.

I know you say that the pinda is diving into the model.

Is it possible that the Model is lifting into the nozzle?

I ask, because if the Pinda strikes the model, and the extruder keeps moving, the model will try and hinge, on the remaining bed contact area, until there is enough energy in the mechanism for the bed adhesion to finally fail.

If the Pinda is pushing on the model as the extruder is moving left, for example the model may twist up and bring the top surface into contact with the extruder nozzle... giving the same, or similar witness marks, but due to a different failure mode.

Are the top surfaces of the models flat, (excluding the disturbance around the divot) if they are not flat, then you may be suffering from warping. as mentioned above, raising the pinda may help mittigate this, but if warping is an issue, you will need to look at ways to resolve that.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: I am so angry. This printer has such a high fail rate.

The PRINDA issue happens when you don't use supports. It is caused by lifting/curling corners. I solved that, by adding extra perimeters. That goes a long long ways towards stabilizing the issue of thin sections curling. This particular issue is one of the nozzle plunging. No, there is absolutely zero evidence of the part not being 100% in contact with the heatbed. (which, by the way, I have the textured heatbed sheet, and I wash it with soap and water regularly) I am 1000% percent certain that this is not a bed/adhesion issue.

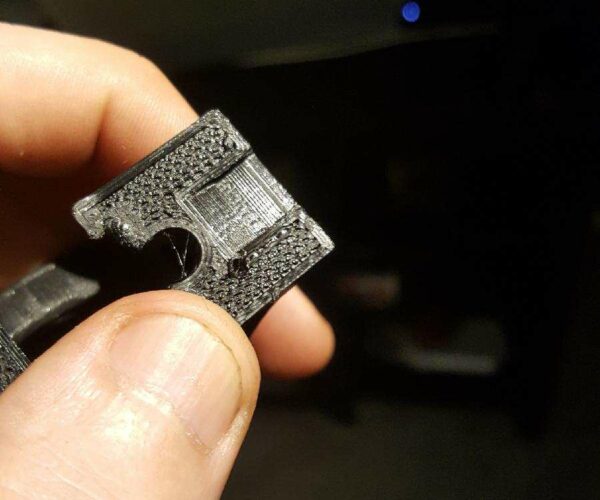

I have a stack of these parts which all exhibit the same type of problem, at approximately (within 1mm) the same location in the build. I've included this one, simply because it's the cleanest, and most definitive example of what I'm talking about.

This problem occurs at all speeds that I've run. 100%, 160%, 64%.

RE: I am so angry. This printer has such a high fail rate.

Do you have collision detection turned on? does the printer show collisions during the print?

what does your display say when the problem occurs?

does the printer try to continue printing? after the problem occurs?

can you share a .3mf file of your project from when that part failed (or the gcode) you will need to Zip it, in order to Attach the file.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: I am so angry. This printer has such a high fail rate.

Unfortunately, I cannot attach the file, as it's proprietary.

However, the collision detection is turned on. But this is usually a one shot deal. Boom. Done.

RE: I am so angry. This printer has such a high fail rate.

Unfortunately, I cannot attach the file, as it's proprietary.

For best results, zip up any files you wish to attach.

RE: I am so angry. This printer has such a high fail rate.

@bobstro

That's not really going to solve the issue of a file being proprietary...

RE: I am so angry. This printer has such a high fail rate.

There is really nothing that will cause the Z-Axis to plunge into a part. A legal command in g-code is about all that can do that. The stepper motor controllers are "controlled" is such a way a random 'zing' into never-never-land is quite unlikely.

Certain types of solid layer infill over the loose infill can cause scalloping, which, when infill percentage is too low, can have surface variation sufficient to catch the nozzle. But your photo isn't showing that.

So we are left with the part snapping off the bed. Since you are using a textured sheet, and using PLA on textured sheets is a known avoidable condition, I suggest you try a smooth PEI sheet, or some sort of adhesion additive.

ps: I think what everyone else is saying, and I fully agree with, unless you provide a model where we can examine settings, you aren't going to get much help. So if that part is proprietary, create something that isn't that exhibits the problem, zip it up and share.

RE: I am so angry. This printer has such a high fail rate.

So we are left with the part snapping off the bed. Since you are using a textured sheet, and using PLA on textured sheets is a known avoidable condition, I suggest you try a smooth PEI sheet, or some sort of adhesion additive.

So I keep having to address this... I use a large brim, and there is absolutely no problem with adhesion. If it were stuck any harder, I'd be worried about damaging the print head with this problem.

Let's face it - you don't fix a problem with strikes by making the workpiece more rigidly attached. That's not proper root cause. You can see in the picture what has happened. I just don't know how much more clearly I can state it. The extruder nozzle plunged into the part. You can tell me I'm wrong until the zombie apocalypse - but I've shown you, and I've seen it happen. On parts with a tighter localized cross section, I've seen the nozzle embed itself, and warble out a melted hole in the part, before breaking it off.

I can't give you this part, because I don't own the design, and it's under NDA. I understand your issue with that, and so I suppose this will just go unresolved. Tomorrow, I am purchasing a MakerBot Replicator Z18, and relegating this piece of equipment to "toy" status.

Thanks for all the replies.

RE: I am so angry. This printer has such a high fail rate.

On close inspection, there is warping - it looks like the part has an overhang (circled) that is warping upward. This is common when an overhang is steep and faced away from the part cooling fan, and repositioning the part so that this overhang is parallel to or facing the fan might help.

RE: I am so angry. This printer has such a high fail rate.

On close inspection, there is warping - it looks like the part has an overhang (circled) that is warping upward. This is common when an overhang is steep and faced away from the part cooling fan, and repositioning the part so that this overhang is parallel to or facing the fan might help.

It may have happened during print, but you can put a straight edge across it now, and not see air.

RE: I am so angry. This printer has such a high fail rate.

Here's an example:

The part on the left gets uneven cooling - the top layer is cooled while the back of the part and lower layers are not cooled. The part on the right facing the fan gets airflow over the top layer and the lower layers and is less likely to warp.

RE: I am so angry. This printer has such a high fail rate.

Perhaps too late, but if the printer is indeed moving the nozzle down into the print mid-print, that is absolutely not normal. OP should log into the online store and contact chat support.

Obvious question is whether printing the Prusa-compiled gcode sample parts yield the same results. Are results the same with different slicers? If the same thing happens with literally every print, just create a 60mm+ high cube, slice it and zip & upload the code here so we can take a look. Otherwise, not much we can do to suggest fixes.

RE: I am so angry. This printer has such a high fail rate.

Of course, you can continue to believe the printer is going rogue and plunging the nozzle into the part; but seriously, it can't happen unless something in your gcode is telling it to.

Or alternatively, the printer electronics are for some mysterious and supernatural reason playing with your psyche. Yours would be the first printer to do this.

As for you part not being warped? You showed us a photo: that photo shows a very clear warp that I circled (the shadows aren't lying). Also, that warp is exactly where the nozzle was banging on the part (melted areas) before it finally broke loose and was sucked up into the nozzle by the surface tension of melted plastic.

RE: I am so angry. This printer has such a high fail rate.

Here's an example:

The part on the left gets uneven cooling - the top layer is cooled while the back of the part and lower layers are not cooled. The part on the right facing the fan gets airflow over the top layer and the lower layers and is less likely to warp.

I am aware of this issue, and that is exactly how I orient my parts. I also add extra perimeters, since it builds from the inside out. This helps, some, but still way too high of a fail rate. For parts over 60mm, I have an 80+% fail rate.

RE: I am so angry. This printer has such a high fail rate.

Perhaps too late, but if the printer is indeed moving the nozzle down into the print mid-print, that is absolutely not normal. OP should log into the online store and contact chat support.

Obvious question is whether printing the Prusa-compiled gcode sample parts yield the same results. Are results the same with different slicers? If the same thing happens with literally every print, just create a 60mm+ high cube, slice it and zip & upload the code here so we can take a look. Otherwise, not much we can do to suggest fixes.

I'll contact them, but I'm gifting this printer to my son. To be perfectly honest, it's too much of a tinkerer's toy. I want a serious piece of equipment, and I don't have time to fool with these types of issues, or to open source my product support.