Hot end explosive deconstruction.

I was performing some basic maintenance on my hot end and swapping to a different nozzle for the first time and noticed the heat break had a slight shift to it after following the Prusa guide on changing nozzles. I didn't think anything of it and figured it was just the angle I was looking at it. Well boy was I wrong. After running the first layer calibration and about mid through a benchy the nozzle went spaghetti monster on me and gummed up. After doing a quick clean I decided to check the Pinda probe again and run a first layer calibration again. Well the calibration gouged the crap out of my smooth PEI sheet while doing the 9 point. What happened is the aluminum block was rapidly forced off the heat brake by the molten PETG because it had destroyed threads from being either cross threaded or severely over tightened.

I have already replaced the entire hot end so this is just me seeing if it has happened to anyone else before.

RE: Hot end explosive deconstruction.

Photos or it did not happne.

--------------------

Chuck H

3D Printer Review Blog

RE: Hot end explosive deconstruction.

I was performing some basic maintenance on my hot end and swapping to a different nozzle for the first time and noticed the heat break had a slight shift to it after following the Prusa guide on changing nozzles. I didn't think anything of it and figured it was just the angle I was looking at it. Well boy was I wrong.

If the heatbreak was angled, that means it was either not properly tightened into the heatsink -- it can work loose if you're not careful -- or it broke. Alignment of the entire hotend, from the top heatsink, through the heatbreak, the heater block, and nozzle is important.

After running the first layer calibration and about mid through a benchy the nozzle went spaghetti monster on me and gummed up.

It sounds like your 1st layer calibration was OK until this point since you got to printing. The gumming up may have been due to filament leaking out the top of your heatbreak.

After doing a quick clean I decided to check the Pinda probe again and run a first layer calibration again. Well the calibration gouged the crap out of my smooth PEI sheet while doing the 9 point. What happened is the aluminum block was rapidly forced off the heat brake by the molten PETG because it had destroyed threads from being either cross threaded or severely over tightened.

Not sure how you managed to check the PINDA without seeing what was going on with the hotend, but it's always a good idea to inspect the entire assembly after doing any sort of work on the hotend, including nozzle swaps. The E3D guidance is pretty good about the required procedure.

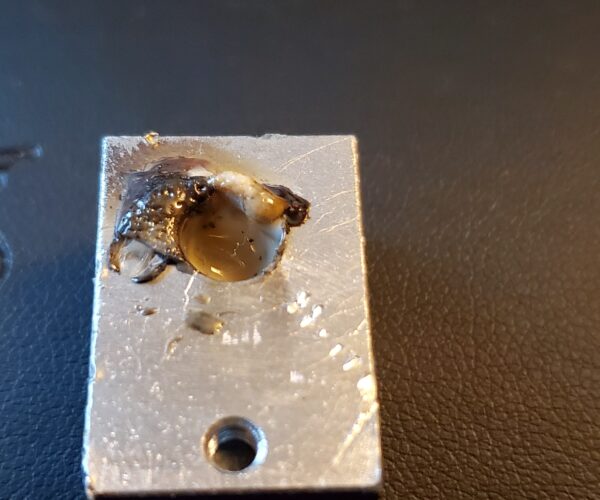

I'm assuming your pics are showing the top of your heater block. That looks like pretty typical leakage that occurs when the nozzle is not properly tightened up against the heatbreak inside the heater block. So to answer your question of whether this has happened to others, yes. If you do not complete the procedure correctly, this is a typical result. Hardly any sort of "explosive deconstruction", but more like a slow leak that you won't notice if you don't inspect the hotend periodically. The nicks along the top do make me wonder what sort of tools you were using.

It's far less common for things to get so badly mangled that the assembly hangs low enough to damage the PEI sheet without being noticed. That makes me think the heatbreak may have snapped and been hanging. Why did you let the 1st layer calibration complete if it was already hitting the bed when printing the prime line? The PEI is pretty durable and can likely still be used. You can try a bit of acetone to remove the embedded PEI, or just flip it over. The PEI sheets are ultimately consumables, and damage is expected.

I have already replaced the entire hot end so this is just me seeing if it has happened to anyone else before.

You could probably have gotten away with just replacing the heatbreak. If it was stripped, the heater block would need replacement. Same for the nozzle. The thermistor and heater cartridge can be damaged in place if they get too gummed up. Having most of a spare hotend on hand is a good idea.

RE: Hot end explosive deconstruction.

Very interesting. Keep us posted when you figure what caused the problem. Very odd.

--------------------

Chuck H

3D Printer Review Blog

RE: Hot end explosive deconstruction.

I didn't notice the leakage because I had a silicone sock installed. The picture with the gob on it is about 1% of what was there after the mess it made. I wanted to know why it separated the way it did and as you can clearly see there are no threads left on that side of the block. I did not tighten the heat break on the block it came that way from Prusa. As stated I already replaced the entire hot end including the thermistor and heater cartridge as the wires were too stuck in the gob of plastic to be saved.

My main concern is has this happened to anyone else or is it just a ultra rare someone overtightened it and it wasn't caught prior to shipping.

RE: Hot end explosive deconstruction.

The silicone sock can make it hard to detect leaks.

--------------------

Chuck H

3D Printer Review Blog