Help printing with FlexFill 98A

Hello, I’m trying to print with FlexFill 98 for the first time in my MK3S. I’m using FlexFill 98A from Prusa and I made three attempts without success. In the first two attempt I was using the PrusaSlicer filament settings for SemiFlex or FlexFill 98A without any modifications, and in the third attempt I changed the retraction length from 0.8mm to 0mm to see if the filament won’t get jammed in the extruder but again without success, it always get jammed in the bondtech gears before the extruder. I'm not using the printer in the enclosure, so the room temp was about 28ºC, I'm a beginner in 3D world but I think the 240º nozzle temp is warming the filament before it gets the extruder.

Print settings:

- 240° nozzle, 50° bed;

- 45mm/s Perimeters;

- 25mm/s Small perimeters ando External perimeters;

- 80mm/s Infill and Solid Infill;

- 40mm/s Top solid infill;

How can I fix this?

Thanks.

RE: Help printing with FlexFill 98A

You are allowed to try hotter extruder, maybe the fillament is not melting enough, and the extruder is pusching to fast for that.

Slower speed you could also try.

RE: Help printing with FlexFill 98A

Hi peter, I’m new to this so I have to ask you some more questions to understand this.

I did not mention in the first post that 2 of 3 times it jammed in the infill, so what speeds do you suggest to slow down and for how much?

The filament box has 210-230° recommended temperature range, I’m already printing above that temp by 10°.

RE: Help printing with FlexFill 98A

a couple of questions.

have you loosened the spring loaded screw for the bondtech gear?

with flexible filaments you don't want the gears to push too hard on the soft filament as it gets fed thru.

i suspect this might be your problem.

another thing, how stable is the temperature of the hotend during the print?

reason for asking is that with my mk3s (was working with plain mk3) the improved part cooling fan can and will activate when doing bridging and this made my hotend drop 20-25 degrees in a few seconds and then the print failed.

i would recommend getting getting one of those blue silicone sockets to put over your hotend (if you haven't already)

it makes the temperature much more stable and i think this problem is why i had sometime issues with PETG and getting first and second layer to stick together properly (going to lower temperature at same time as part cooling fan comes on on second layer creates a big drop in temp without the silicone socket)

RE: Help printing with FlexFill 98A

Change the speed settings to 20mm/s max for everything!

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Help printing with FlexFill 98A

@torbjorn-j3 yes I have loosened the spring loaded screw for the bondtech gear after first jam because I thought the same. I didn’t get an eye on temperatures while printing, but if I remember correctly the fan didn’t kick in for the first 5 layers at least but I will keep an eye on that. I noticed already that when printing PLA or PET that happens and the temperature drops 15/20°, I’m earning for that blue silicone socket for the first time, I’m getting started with 3D printing, will google that.

@nikolai-r will thy that also on the next try!

Thanks for helping out guys, I’ll post my feedback here after I give another try.

RE: Help printing with FlexFill 98A

[...] I did not mention in the first post that 2 of 3 times it jammed in the infill, so what speeds do you suggest to slow down and for how much?

The Prusa infill speeds are too aggressive. Change it to match whatever speed you're using for perimeters that isn't causing problems.

RE: Help printing with FlexFill 98A

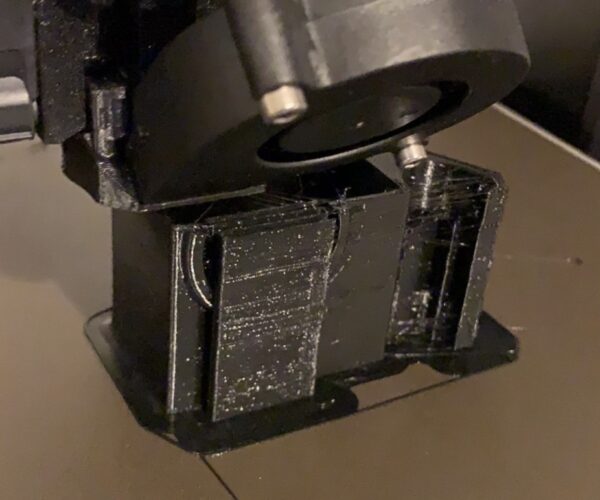

Good morning, tested again today with retraction off and all speeds at 20mm/s but again with the same problem. It jammed before the fan kicks in so the temperature drop was not the problem, I have loosened the spring loaded screw for the bondtech gear a little more but I think it was a little too much this time.

Here you have two photos, one with 3 failed attempts and the other is from today witch you can see even on the first layer the filament already getting jammed:

RE: Help printing with FlexFill 98A

No big help, just to tell you are not alone -same problem here!

Best Regards,

tox

RE: Help printing with FlexFill 98A

If you have jams on the first layer, then you have to adjust the live-z. Bring the nozzle up. Looks like you get a lot of back pressure. You can fight this with:

- Lower the speed (15mm/s, 10mm/s)

- Reduce the extrusion amount

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Help printing with FlexFill 98A

I've only printed a few items with flex, but they came out perfectly on my MK3S (I used 3D Solutech Flexible Filament). All I did was:

1) Used PrusaSlicer

2) Selected default Filament profile of "SemiFlex or Flexfill 98A"

3) Loosened spring screw on bondtech gears to as loose as possible

Not sure what is causing your issues, but I feared all the custom changes I might have to make after reading all I could about printing flex, but literally had to do nothing custom - just chose defaults above and loosened gears.

RE: Help printing with FlexFill 98A

Nothing helpful to say just needed to post to subscribe to this topic. [ maybe there is a better way]

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Help printing with FlexFill 98A

@chris-z

I don't understand, but following this rules worked out for me also.

What I don't understand is, that my first flexprint worked flawlessly (I didn't change anything) - but after that, the transport mechanism eats my flexfill every time ... sometimes it took 3 hours ... sometimes only one hour or even less.

loosen the screw as much as possible helped - hopefully also the next time 😉

Thanks a lot for pointing that out here

RE: Help printing with FlexFill 98A

I have recently bought the MK3S and have come across the same problem with Flexfill 98A filament whereby around an hour into the print the filament would bend and clog at the gears, the same as yours @francisco-g4. After spending a day playing around with the idler tensioner (so it was held in by a single thread), retraction settings, speeds (even setting the max volumetric speed to 1) and hot end temperatures; I decided to contact support on the shop page. After a chat with the helpful advisor they asked about the temperature of the extruder motor during prints. I recalled that when the prints failed I noticed the extruder motor was very hot to the touch. Turns out my extruder motor was heating up the gears and in turn the flex filament which caused it to buckle.

Solution: The advisor sent me the following line of g-code to add to set the extruder motor to a reversionary mode (lower current draw), reducing the temperature of the motor during operation. This seems to have worked as the first print while using the code resulted in a lower temp motor and a successful print (find attached the failed and final).

Code: M907 E410 ; SET LOWER EXTRUDER CURRENT

RE: Help printing with FlexFill 98A

“have you loosened the spring loaded screw for the bondtech gear?”

Does this mean the gears would “slip” on the filament, where tight gears would deliver the full geometric pitch? Why not just slow down the extruder speed to match the flow capability at the nozzle?

Every man I meet is in some way my superior. --Ralph Waldo Emerson

RE: Help printing with FlexFill 98A

@armedleftist

To get the gears near the slip moment is the trick. That means during regular, good scenarios it doesn't slip. But once there is too much resistance the gears would slip instead of pushing the filament out of the filament path.

Slowing the speed, increasing temp, reducing retractions is something you have to do anyway.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Help printing with FlexFill 98A

@armedleftist

To get the gears near the slip moment is the trick. That means during regular, good scenarios it doesn't slip. But once there is too much resistance the gears would slip instead of pushing the filament out of the filament path.

Slowing the speed, increasing temp, reducing retractions is something you have to do anyway.

Understood. That said though, it seems like tweaking to find the exact right tension setting is more work, and potentially even less effective, than simply determining the hi/low flow window and then setting extruder speed to “play” at both extremes. Then “slip moment” would be irrelevant in all but the most extreme cases (eg, when the hi/lo flow range is tiny.). Personally, the less variables I am working with, the happier I am and the better results I seem to get.

Every man I meet is in some way my superior. --Ralph Waldo Emerson

RE: Help printing with FlexFill 98A

@francisco-g4

I wonder if you have an un-flat print surface? Looks to me my there is a fairly significant z-delta between the lines in the red circle, and those immediately next to the circle to the right. The ones on the right look much more “ironed”. Can’t tell if it’s perhaps simply a leveling issue. Have you tried the old straightedge-on-bed-shine-flashlight-from-side trick?

Every man I meet is in some way my superior. --Ralph Waldo Emerson

RE: Help printing with FlexFill 98A

I haven't printed in anything other than PLA, but I want to try flexible filaments. My question is regarding the initial filament loading, because as the sensor is triggered, the bondtech gears spin quickly to load the filament - is this an issue with flexable filaments?

Texy

RE: Help printing with FlexFill 98A

I haven't printed in anything other than PLA, but I want to try flexible filaments. My question is regarding the initial filament loading, because as the sensor is triggered, the bondtech gears spin quickly to load the filament - is this an issue with flexable filaments?

Texy

I have had this issue with my flexible (really soft 85A). Not every time, but often enough that usually when I'm getting ready to load the flex I turn off autoload and manually advance the E-axis to better control the feed rate.

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs