first layer failure and can't get a decent calibration

I have been printing on my Mk3S for a couple of years and lately after first layer failures, I have tried recalibrating and can not even get the calibration to work. The lines don’t stick and the final patch at the end is threading instead of pressed down/adhering to the plate. I have tried a full calibration twice and changed filament. I changed out the hot end about 9 months ago after a huge blob failure completely encased my original hot end. I print in PETG. Not sure where to start with fixing this. Any tips are appreciated.

RE: first layer failure and can't get a decent calibration

Sheet type and a photo of the symptoms will help immensely.

ps: as a guess, measure the height of the PINDA when the nozzle is touching the bed (must be done manually). The PINDA might be triggering early ... making your Live-Z values ineffective.

RE: first layer failure and can't get a decent calibration

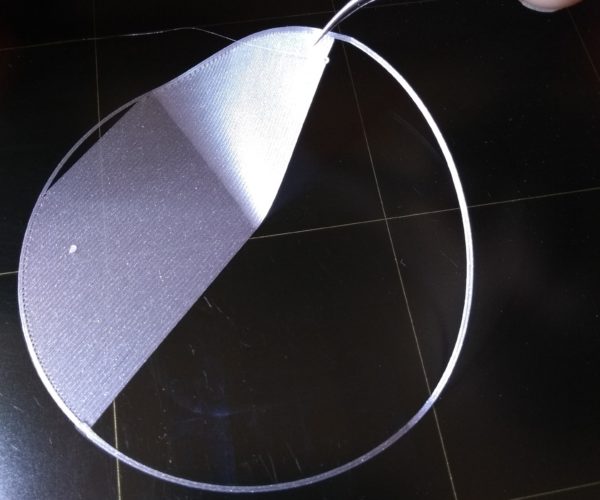

I was printing on the textured sheet with black Prusa PETG and I switched to the smooth sheet and orange PLA so that you can see it better. This is exactly the same as what I was seeing with the previous filament and textured sheet. This is a -0.335 calibration. If I go closer it begins getting bumpy like a caterpillar.

RE: first layer failure and can't get a decent calibration

@tim-m30

Triggering early which means that I need to raise the PINDA? One thing that I noticed is that in past calibrations (i.e. before I changed the hot end) the nozzle nearly touched the bed and almost grabbed the paper. But in the latest calibrations I would say that the nozzle is not even coming close to the bed. Raising the PINDA a couple of millimeters is something that I've been thinking about.

RE: first layer failure and can't get a decent calibration

When the nozzle is resting on the print sheet - the PINDA should have a 0.8 to 1.2 mm gap - the thickness of the feed end of those small cable ties that came in the kit. The PINDA senses metal at 2mm. I prefer the lower end of that range.

That last test looks a bit odd. Try this test print - you can adjust Live-Z while it is printing, and have time to see results and make several adjustments as it prints.

RE: first layer failure and can't get a decent calibration

Clean bed with dish soap , then the bed is 100% clean, alcohol does not clean everything.

Your picture looks like the first layer possible to high,

or there is not enough filament coming out of nozzle, possible partially clog, do a few cold pulls or change nozzle.

Use 7x7 setting for calibration in the printer settings.

RE: first layer failure and can't get a decent calibration

I lowered the PINDA slightly and tightened my Y directional belt and am back to printing. I also think that I am not getting full flow from the nozzle and will try a cold pull or a new nozzle if that doesn't work. Thanks for the comments and your support they helped solve my problem.

RE: first layer failure and can't get a decent calibration

@tim-m30

How do you adjust the PINDA sensor up/down? Looks like it is threaded, which means you have to free up the cable going into the PINDA sensor so that it can turn. If it is friction fit, then no need to turn the PINDA sensor.

RE: first layer failure and can't get a decent calibration

@mike-mccoy-3421

The plastic is not threaded - you can loosen the clamp screw, and the PINDA will move up and down. The plastic is probably scored, so it is "sticky" and wants to go back to where it was, but you can adjust it in small amounts. Use a small screw driver to wedge the clamp open just enough you can move the PINDA, pull out the wedge when you get the altitude right.

On a 3 year old machine, the notches in the plastic are tenacious, but I just adjusted my PINDA, so it is possible. Patience is the key.

RE: first layer failure and can't get a decent calibration

@mike-mccoy-3421

Yes as Tim-m30 mentioned I found that I had to use a small flat blade screw driver to pry the clamp open. It doesn't take much but it does require a fairly sharp blade on the screw driver. I also had to use the tip of the zip tie which was a bit smaller than the middle. The ridges in the PINDA do make it a bit tricky, and it took me a few tries to get it where I wanted.