RE: Crash detection not working with powder-coat sheet

@tim-m30

My point is referring to one of the Prusa supplied sheets as "the PEI one" and the other as "the other one" isn't enough information to determine which of the two Prusa supplied sheets is being discussed. 😉

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: Crash detection not working with powder-coat sheet

@tim-m30 - Is that a helicopter blade?

I did try printing a smaller version of the fin standing on its leading edge. The problem is the trailing edge thickness is limited by the nozzle diameter, so that's why I tried printing it laying flat... which resulted in this thread.

I could buy a 2.5mm nozzle but I'm seeing what I can do with 4mm. Printed on its side, I can get a much thinner trailing edge. I'm also considering printing it standing up vertically from the fin root, in which case I might even be able to print it as a spiral vase, but I'll still run into the problem of ending up with a too-large radius at the trailing edge. I think I can't avoid some finishing work no matter what I try.

One thing I've noticed is PrusaSlicer's "detect thin walls" setting results in PrusaSlicer showing a jagged thin edge that isn't even connected to the part. So far none of the 3d models I've made are improved by that setting. It seems to be best for thin walls that are connected by something more substantial at each end, not a thin wall with one free edge.

RE: Crash detection not working with powder-coat sheet

@tim-m30

My point is referring to one of the Prusa supplied sheets as "the PEI one" and the other as "the other one" isn't enough information to determine which of the two Prusa supplied sheets is being discussed. 😉

The reason being that both the smooth sheet and the textured ones are "PEI Sheets". Just a different method of application - and texture. And use characteristics...

RE: Crash detection not working with powder-coat sheet

Okay -- in my opinion you are chasing rainbows and running into a hurricane by trying to print the fin with rafts. As for trailing edge and overall performance with FDM printing, I'm not an aeronautical engineer, but my brief experience modeling airflow simulations years back say that too is a rainbow you'll never reach. The difference between a 0.4 mm trailing edge and a .05 mm trailing edge is insignificant compared to drag induced turbulence of the foil surfaces; and magnify the ideal with the roughness of a rafted surface ??

RE: Crash detection not working with powder-coat sheet

@tim-m30 - those are good points. In this case, a 0.4mm edge is 20% of the average thickness of the airfoil. It's not so bad at the fin root, which is 4mm thick, but the thickness tapers to 2mm at midspan and down to 1mm at the tip.

My simulations show that drag coefficient is the largest contributor to altitude loss for this rocket, especially since the majority of the flight is ballistic (thrust lasts about 0.1 sec after which it's traveling about 180 mph). This is a competition so every little thing helps.

For now, though, I'm interested in learning how to print a sharp edge. I'm resigned to the fact that I will have to finish the part with sandpaper, whether it be roughness from the support points, ridges from layers, or roundness on the trailing edge.

RE: Crash detection not working with powder-coat sheet

If printed with finishing in mind, you can create the fin and provide plenty of material for strength. No need to lay it down because I know the result will not be usable for you project. Even with serious planning supported finishes are not anywhere near smooth.

Splitting the fin and gluing the two sections will get you fair layer steps to sand without too much material removal; but printing tall, root down, tip up, will give the least finishing work. Yes, the trailing edge will need more material removal, but the rest of the fin will need far less sanding. And all of the surface can be fair to begin with. For the final model, using a 0.25mm nozzle is probably the best way to go. Heck, even splitting the fin so the trailing edge is printed flat, the remainder printed vertical is worth exploring. But the layer steps still may be more work and drag that the thinner layers will gain. Sanding the final edge from a vertical print still seems best. And there are 0.15 mm nozzles out there.

Excuse the crude sketch...

RE: Crash detection not working with powder-coat sheet

The last bit of tail is single layer, only one half has it so it is only 0.05 mm thick (can you say super fragile).

Silly forum is cropping the image, click to see what's there.

How does the OP get around the firmware limitation of 0.15mm minimum first layer for that trailing edge?

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: Crash detection not working with powder-coat sheet

@tim-m30 - Thanks. I had also considered printing the airfoil in two halves flat on the bed so that no support is needed. I hadn't thought of extending the trailing edge of one half to get a thin edge. That's a good idea.

To manage the roughness of support, I was going to buy the MMU2S and use it with PVA support material. I still plan to buy it, but not for this fin. Ideally I would print this fin with HIPS for the lightest weight, but I don't know of any dissolvable support that would work with HIPS (which is itself is used as support for PETG).

For printing standing up at the root, I could also add a 0.45mm trailing edge extension to the model, for sanding off later, so that I don't have to sand into the airfoil profile at the edge.

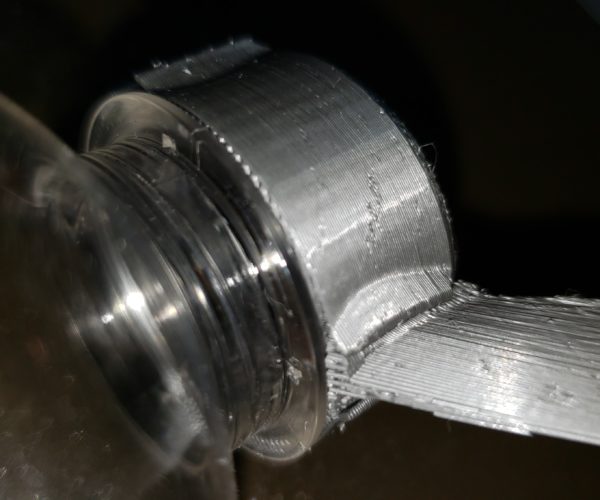

I need a big brim to print it standing up, though, because the root is small:

The "foot" at the root fits into a slot in that retaining ring (although I wouldn't print these at the same time). That retaining ring was the most difficult part I designed, using Tinkercad. It screws onto a soda bottle (and fits perfectly). I've printed the retainer and the fin root through enough iterations that they now fit together well. Here's a photo of an early test, with a small fin printed from its leading edge (which looks messy, my first layer calibration was off back then):

My final problem to solve is the fin edges.

A small part of the fin near the root is in a turbulent flow zone, so the trailing edge doesn't matter there, I suspect it's better to limit the surface area. The widest part of the fin is in non-turbulent flow and needs to be well-shaped.

RE: Crash detection not working with powder-coat sheet

How does the OP get around the firmware limitation of 0.15mm minimum first layer for that trailing edge?

By sanding it a bit? 0.15mm is way thinner than the 0.45mm width of a perimeter. I'd be happy with that. If not, a little bit of live Z adjustment can flatten it further.

RE: Crash detection not working with powder-coat sheet

The last bit of tail is single layer, only one half has it so it is only 0.05 mm thick (can you say super fragile). Silly forum is cropping the image, click to see what's there.

How does the OP get around the firmware limitation of 0.15mm minimum first layer for that trailing edge?

Silly user thinks in single dimensions (me). Of course he probably can't; no clue what I was thinking, blame it on the hour. First layer will / should always be 0.2 +/-. But then, I just told slider to use 0.1 and it was happy. The o.15 is used for the purge lines, though I have never tried to print a 0.05 first layer, so I personally don't know if it is impossible due to firmware limits.

RE: Crash detection not working with powder-coat sheet

In theory if you reduce live-z by 0.1 you would print the first layer as firmware 0.2 - 0.1 so in effect 0.1mm, I also think you would have to adjust your first layer extrusion to half of it's current setting, but I wouldn't try this on a textured sheet as I find there is too much thickness variation with the textured surface and you risk crashing into the surface high points.

Your much better off with a smooth PEI surface for PLA printing anyway, the textured surface is best for PETG.

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.

RE: Crash detection not working with powder-coat sheet

Yeah, I may just go ahead and order a smooth PEI sheet. Another advantage to that is that if it's smooth, separate parts could be glued together more cleanly, no?

RE: Crash detection not working with powder-coat sheet

Parts warp in the strangest of ways, so ymmv with glue success. Some parts print well; other parts do weird things, like a bowed based that didn't lift off the bed, but bowed after the part was removed, and was no longer flat enough to glue to its mate.

RE: Crash detection not working with powder-coat sheet

@tim-m30

OK, I printed the fin vertically, standing on its root, with 0.20mm layers. The trailing edge near the root had to be printed as an overhang (slightly worse than 45 degrees) and came out pretty rough. Maybe printing support material would help. The elliptical section's trailing edge came out rather nice, if a bit non-sharp:

Some light sanding cleaned up and sharpened the edges reasonably well. I have only 220-grit and 3000-grit sandpaper on hand, so some grits in between would have better results, but it looks promising:

The only real concern I had during this print is, when it was done, I barely touched the fin and it came off the print bed, even though I had a 10mm brim all around. It looks like it's time to do another soap+water wash on my powder coat sheet.