Please help with continuous failing

I am getting frustrated with trying to print desparately needed faceshields. I am totally new but feel my live Z is good although I can't tell much difference until the first layer about squishes flat, then I back it off. I am printing Prusamint PETG. The first print is on a smooth sheet witht he printer sitting on a 6 foot plastic folding table. These layers look very different than my first layer calibration as well as very uneven. Also, why are those layer dragging out of positoin?

So I switched to the textured sheet, redid first layer calibration and tried the same print off the Prusa site and SD card. I cleaned the surface with ISP and it the PETG would not hold in place causing me to abort quickly.

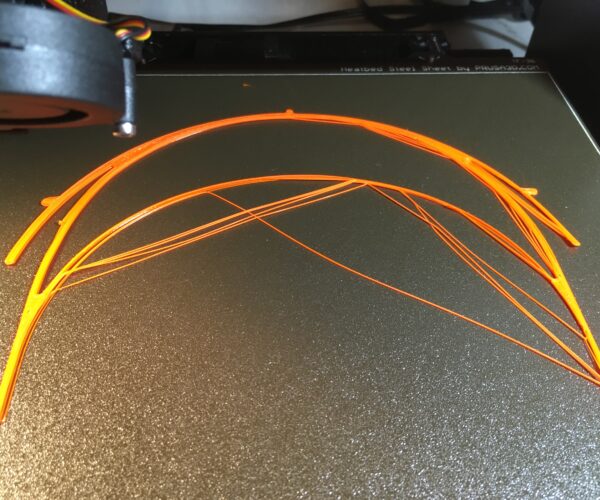

Finally I tried a different print and this was the worst yet.IMG_5193

Any help appreciated some I can produce some shields for my wife's staff at her facility for the mentally handicapped.

thanks

RE: Please help with continuous failing

First of all, for something like a face shield printed vertically, I would use a smooth sheet.

Other than that it looks to me to be an adhesion issue with the first layer. If you are confident on the Z calibration and that the surface is completely clean, the next thing I would do is inspect the nozzle area for anything ('boogers') hanging down and pulling the extruded filament from the print bed.

I've gotten into the habit of carefully inspecting the nozzle before each print, and if there are any 'boogers' or 'drool', getting them off with a brass wire brush. Just be careful not to use a wire brush on the hot end thermistor.

Since the contact area of that print with the bed looks to be very small, maybe a brim or even a raft may give you better luck.

RE: Please help with continuous failing

@jsw

Thank you for answering. I am, let's say false confident because although the manual shows pictures of a good first layer, I am still guessing at what looks best. In my live Z I take the print down until it looks flat then back off until it gets slightly rounded, usually around -.650. However the first print above was on smooth sheet but the layers look anything but smooth and tight. It looks like a pile of rope. I don't know what the brim and raft are but will look it up. Thanks again.

RC

RE: Please help with continuous failing

Give more info.

picture of your first layer?

temp printing? Your whole print settings.

Try to print with thin layers on?

A new sheet will stick less then a used one.

PLA sticks more difficult on a powder coated sheet. Is still possible settings need to be more preciese.

This how I work on a pei sheet(there are always exceptions):

Most important to 3d printing is:

1. 3d print will never be like start and i have the print, there will always be problems!!!!!!

2. A clean sheet, use dish soap, then you can print on it. A few prints you can use alcohol, then again dish soap,

big flat models and models with small footprint on sheet- use glue stick(and not every glue stick is the same,

use one that makes a thin layer), and big flat models and small footprint, use a big brim attach to model so footprint is bigger.

Petg sticks to much on the pei sheet, use window cleaner, this leaves a layer on the bed, so it does not stick to much.

3. To get it stick very good, a 100% first layer is very important, see youtube for movie on this.

Every new print watch the first layer, and look if it is 100%, this will also prevent a big ball of filament on your nozzle wen model let loose during printing.

Extra: (normally not needed).

First layer, print hotter.

First layer slower.

Bed more heat.

Most problems are first layer to get this 100%, and bed not clean.

Bad filament is possible, or filament with water inside.

Move extruder to the top and extrude filament, it should go straight down(if not, nozzle possible blocked),

it should be thick enough(if not, nozzle possible blocked, or partial blocked), (do a cold pull),

if Bubbling during extrusion then it has to much water inside.

Check after the first layer is ready, then you see if it sticking enough, and not releasing and sticking to the nozzle.

If you see white spots like a bubble on the bed, then filament is releasing from bed.

Also no gabs between lines should be visible.

Use 7x7 calibration for first layer, see settings in the printer.

RE: Please help with continuous failing

@rcurschman

Look for the topic:

life adjust Z - my way

There are links to download a calibration square that is way more accurate in getting z adjust to how you want it.

While your printing the square you can adjust z till you get the first layer height how you want it.

Type the topic just as I have typed it.

Also your bed temp should be hotter on the first layer for adhesion. The stringing across the model is the travel of the extruder going to fast. I make my first layer speed 10s/mm. It's slow but it also helps my extruder to extrude enough filament evenly on the first layer. First layer is important.

Hope this helps.

PS; How long have you had your printer?

RE: Please help with continuous failing

First layer speed 10s/mm is normally not needed, then there is something wrong.

But if you need to print and it works at the moment.

RE: Please help with continuous failing

@peter-m26

Thank you! This is great info to know. I am realizing that this seems to be a reactive process. See what the printer is giving you and adjust to that. I will do the live-z my way and report back. Cheers

RC

RE: Please help with continuous failing

@mr-b

I have just received the printer and only tried to print a few times. I am realizing I have to learn the adjustments to make. I hope the Live-Z shows me the correct size first layer because I am guessing right now.

Cheers

RC