Please help, I've given up

I know the title isn't very helpful, but I'm honestly at my wit's end with my printer and I don't know what else there is to do.

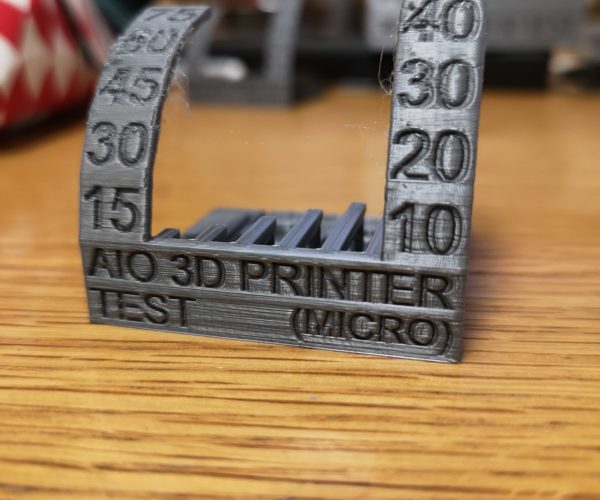

I've had my Prusa i3 mk3 for about 5 months now, and I have tried every single diagnostic that I possibly can to get it to do a good print and I just can't find what I'm doing wrong. I'm not even sure I know how to describe the issues I'm getting, but you can see from the diagnostic all in one tests that I printed from Thingverse, I'm getting stringing, inconsistent layering and adhesion, and not great bridging. The images below are from my latest test done using Prusament PLA at 200C (to cut down on stringing which kind of worked?) using a .6mm nozzle. I'm using such a large nozzle because I'm planning to print in woodfill PLA and I want to get it right using that size of the nozzle before I start printing in that, although these issues were in effect when I was trying to print using standard nozzle as well.

So far I have done more live z levelling than I care to mention, I have changed the PTFE tube, I have checked the position of the PINDA sensor, calibrated the extruder stepper, done various temperature settings... I'm just not sure what there's left to do and I'm still not getting a huge amount of difference in the quality of my prints. I'm obviously missing something but I can't work out what it is and I'm about ready to sell my printer at this point which I don't want to do because I have so much I want to do with it.

If you have any thoughts or advice, I could really do with it.

RE: Please help, I've given up

1: Use the DEFAULTS. I use Generic PLA and Default 0.15 Quality or 0.20 Quality for most everything. Anything else will force you to chase your tail. Sure, I tweak things, but only when I have a reason too, like adding perimeters or changing infill ratio.

2: Use the defaults. I have never found filament really needs higher or lower temperatures to print well. Some filament strings, and I have never found a setting that actually helps. Heck, I've seen stringing come and go in the same print, all because of air in the room does something different.

3: Keep the bed meticulously clean. One finger print will ruin a print. Soap and water works: but requires a sink with running HOT water for rinsing. Never touch the bed print surface with hands or fingers, and only use fresh plain paper towels to wash and dry at the sink.

4: Speed is your enemy for printing. Faster prints means less quality.

5: More layers allow overhangs to work better. If printing an overhang test, use 0.10 layers.

6: DON'T change nozzles unless you follow the E3D-V6 assembly guide to the letter. Skipping even one small detail results in poor print quality.