New User - First Run Problems

Hi All,

New user here with a Prusa i3 MK3 - pre built unit - latest firmware. How easy should the first print be from the SD card file (prusa logo)

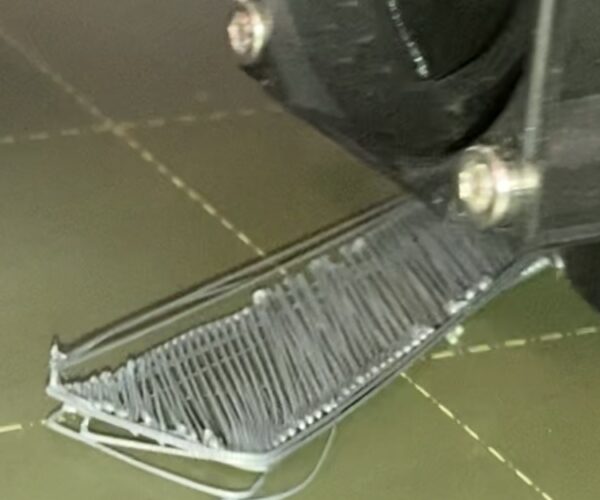

I have run the calibration wizard through no errors. When my print starts the extrusion looks very spaghetti like and doesn't melt into smooth layers. The base also doesn't stick well and the whole print gets picked up by the nozzle in a few minutes. The end result of the Prusa logo is in the picture.

The base is cleaned with IPA no grease and I'm using pre supplied PLA silver material at recommended temperatures. I cant see the nozzle fan operating at all during first layer is this normal? Ambient temperature is low here about 10-15 deg C

Any advice appreciated as was hoping to get up and running out of the box.

Shawn

RE: New User - First Run Problems

Your first layer is to high.

Wen you start a print, wen the left strip is printed in the beginning, in the menu of printer, there is a first layer adjustment calibration,

this you need to adjust, see manual with pictures.(you are to high, a lot).

Read the manual!,

watch youtube examples, with

first layer calibration, then you learn how to.

And of course read this forum.

And if you do not now, a 3d printer will never be like , model on sd card and print, and I do not have to do anything, you always need to adjust,

that why read the forum old threads, then you get live problems of users, and that will happen to you to!!!!!!!!

RE: New User - First Run Problems

What Peter said. First layer is WAY too high.

On the fan question, it is normal for the parts fan not to be active on the first 1-3 layers depending on what material profile was used to slice with. The default PLA filament profiles dont turn it on for the first layer, the default PETG profiles have it off for the first 3 layers. Its a value you can change in the slicer settings at the time the gcode file is created.

RE: New User - First Run Problems

Thanks guys, must admit I thought a pre built unit would be pretty close to being ready to go. It had the prusa logo on the bed when it arrived.

I have now adjusted the bed closer by value of -1.100 and its now printing really cleanly as expected. I'm going to leave it to finish 🙂

Shawn

RE: New User - First Run Problems

Here's a copypasta info dump with detailed information for users new to Prusa printers and the Live-Z process:

-

A dirty PEI print surface. Even if you don't think this is the cause, it's always a good idea to make sure your PEI surface is clean before trying any other fixes. If it's a smooth PEI sheet, take it to the kitchen sink and give it a good dunk with Dawn (original formula, no vinegar or hand softener variants) dishwashing soap or your local equivalent (e.g. Fairy in UK). Use a clean paper towel to clean it off, and another to dry it. Avoid using any sponge or cloth that has been in contact with grease. Above all else, avoid touching the PEI print surface. Once it's good and clean, you should be able to use 91%+ isopropyl alcohol between prints, 100% acetone when that fails , and another dunk when acetone fails. Worst-case, use a 3M 7445 (1200-1500 grit) ScotchBrite pad or equivalent on smooth PEI to give it a very light buff, but only infrequently. If you've got a textured powder-coated PEI print surface, the official instructions are to use 91%+ isopropyl alcohol on it only. Rumors persist that some have had good luck getting started with these sheets by giving them a wipe with 100% acetone and a dunk with Dawn. Either way, there's no real warranty on these sheets. YMMV.

-

If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the onboard routine and much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers. You should not be able to peel the lines apart after printing, but the top should be regular.