MK3S belt tension - how to adjust

What is the best way to adjust belt tension on a MK3S? The surfaces of my prints are not perfectly flat but have a bit of profile. I wonder if my belts are properly tensioned. The tension seems a bit low. The score in the Belt status display are x: 251 and Y: 270. Also round object come out pretty round. Can I consider this item "checked" and look for other tunings or is it worth while digging deeper?

Best Answer by jsw:

I do not have enough of a feel for those 'belt numbers' to know how indicative or accurate they really are.

I've always adjusted belts of this type, on the Prusa printer and on other devices by feel. It's one of those things where it's hard to describe, but you know the more-or-less proper tension when you see it, or in this case feel it. (Hear it?)

TFM says that they should sound more or less like a bass guitar string when plucked. I would counter that with 'which string?' and that not everyone knows what a bass guitar sounds like. 😉 If it flaps instead of making a sound, it's probably much too loose, and your prints do look like you could have loose belts.

If you want the guitar guideline, I would say that if it's about the sound of the E string on a bass guitar, it's probably close to correct, but if it's closer to the sound of the low E string on a regular six-string, it's much too tight.

I would suggest that you simply apply some gentle pressure on the belt. It should definitely show some resistance to your finger, but should not be so tight that its movement is difficult. Of course, it should not be so loose that it can easily slip a notch, nor so tight that it binds the free movement of the device.

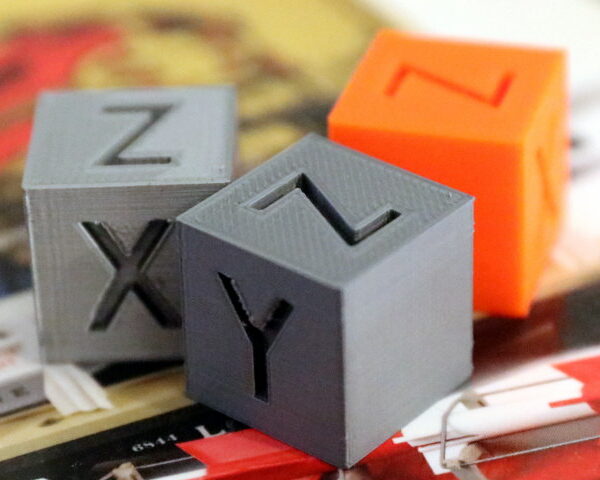

In the photo below, which shows 20mm test cubes in ABS, PLA and PETg from left to right, you'll see on the ABS cube that there is some slight ringing, but not nearly as much as in the print you posted in another thread. I would say that when this cube was printed (some time ago) it could use a tweak of the belt tensions.

Also from the PLA (center) cube, you can see the top, and you should be able to consistently get this degree of smoothness or better from your MK3S.

I would start by tightening the belt(s), as I think you probably have a way to go.

I would also suggest that you print some test cubes, something like this or similar: https://www.thingiverse.com/thing:38108

This will give you a good feel of how the surface quality of your machine is doing. You can do a test print, make some tweaks, and then another print to see what and how much are affected with what you adjust.

RE: MK3S belt tension - how to adjust

Referring to the topic 'Flat surface quality ok or up for improvement?' it is very likely the printer is suffering from Ringing. Also I read on 3D Printing:

If you have 3D printer ringing, check your belts first. They should be tight, sounding a low note if plucked. If you find they’re too loose, follow your manufacturer’s instructions on how to tighten them.

My belts do not make any sound at all. They almost show a sag. Still the Belt status number are ok (ref to my first post). Are these numbers reliable?

RE: MK3S belt tension - how to adjust

I do not have enough of a feel for those 'belt numbers' to know how indicative or accurate they really are.

I've always adjusted belts of this type, on the Prusa printer and on other devices by feel. It's one of those things where it's hard to describe, but you know the more-or-less proper tension when you see it, or in this case feel it. (Hear it?)

TFM says that they should sound more or less like a bass guitar string when plucked. I would counter that with 'which string?' and that not everyone knows what a bass guitar sounds like. 😉 If it flaps instead of making a sound, it's probably much too loose, and your prints do look like you could have loose belts.

If you want the guitar guideline, I would say that if it's about the sound of the E string on a bass guitar, it's probably close to correct, but if it's closer to the sound of the low E string on a regular six-string, it's much too tight.

I would suggest that you simply apply some gentle pressure on the belt. It should definitely show some resistance to your finger, but should not be so tight that its movement is difficult. Of course, it should not be so loose that it can easily slip a notch, nor so tight that it binds the free movement of the device.

In the photo below, which shows 20mm test cubes in ABS, PLA and PETg from left to right, you'll see on the ABS cube that there is some slight ringing, but not nearly as much as in the print you posted in another thread. I would say that when this cube was printed (some time ago) it could use a tweak of the belt tensions.

Also from the PLA (center) cube, you can see the top, and you should be able to consistently get this degree of smoothness or better from your MK3S.

I would start by tightening the belt(s), as I think you probably have a way to go.

I would also suggest that you print some test cubes, something like this or similar: https://www.thingiverse.com/thing:38108

This will give you a good feel of how the surface quality of your machine is doing. You can do a test print, make some tweaks, and then another print to see what and how much are affected with what you adjust.

RE: MK3S belt tension - how to adjust

@jsw

Thank you for your extensive answer. At this moment my conclusion is my belts are not tight enough. I also tend to conclude the belt tension number shown in the LCD display may not always be fully reliable. I'll inform Prusa support about this.

RE: MK3S belt tension - how to adjust

Another test you can make for belt tension is to hold the stepper motor shaft with pliers and try to move the plate or the extruder. There should be no significant movement, as in no 'slop' or 'play' of any significance.