Minor axis catching - E axis - First Print Troubleshooting

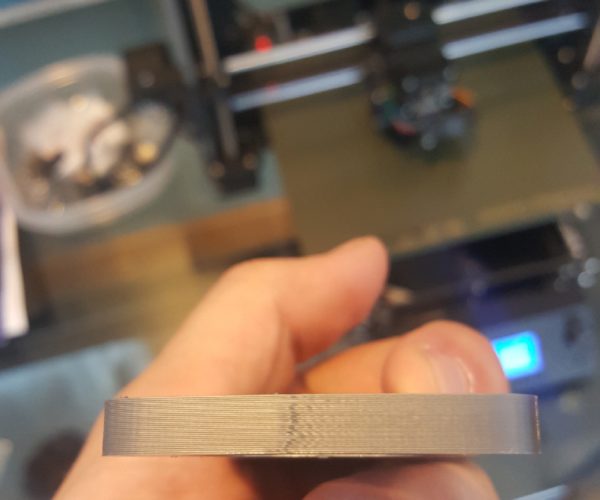

I just finished assembly of my MK3S last night and so far no major issues! There is a minor problem I'm facing, that I believe I know the source of, but wanted outside opinion and advice. There is a small, consistent shifting of the extruder as it moves along the rails of the x axis. From what l can see, the extruder catches just slightly in the center of the x axis rods, leaving minor errors down the part. See pictures below. I think I need to make sure the rods are perfectly square and properly lubed. Other ideas appreciated, thanks!

RE: Minor axis catching - E axis - First Print Troubleshooting

That sort of makes sense: the infill is printing faster than the perimeters, and why the artifact is only in the infill. Check the LCD under "belt tension". While not what you should use to set belt tension, it does give you a fair indication of axis friction. Anything below 260 is a problem, and closer to 300 best.

Another possible cause is a loose belt drive gear. If not installed using a very specific procedure, a gear can wiggle on the shaft. Set screws must be installed flat first, then once properly aligned and torqued, only then tighten the second jam screw on the shaft round. Done any other way, the screws will come loose.

As for bearings: if you did not pack them with grease before inserting the rods, they will cause you problems.

RE: Minor axis catching - E axis - First Print Troubleshooting

Hey - another gent had an exact infill artifact like your, and it occurred to me his belt drive gears might be the cause: he chaecked, and sure enough one was loose.

Flat First: Drive gears must be tightened flat-first.

1) Start with both set screws fully loosened so the pulley is free to spin on the motor shaft.

2) Align one set screw dead center with the flat on the motor shaft, slowly tighten the screw until it fully contacts the flat surface.

3) Torque the flat set screw to spec.

4) Now tighten the jam set screw, and torque it to spec.

Once tightened, never touch the flat set screw unless the jam screw is first fully loosened.

Why Flat First? Set screws have flat ends. If you tighten the jam screw first the set screw on the shaft flat doesn't fully contact the shaft, only one small edge of the screw surface is biting. Reversing torques can easily shift the shaft to a position the flat screw no longer contacts the shaft. This lets the jam screw wriggle loose. And after a while, vibration loosens the screws until the gear is free to rotate.

RE: Minor axis catching - E axis - First Print Troubleshooting

Thanks for the follow up! I did some reading and ended up doing exactly what you reccomend, checked the pulleys and sure enough x axis was loose. Tightened it and everything thing since has printed beautifully. thanks for your help!!