Grease on bottom X rod shows black after 130 hours

The other day I was printing after having a very good day printing the day before. I had to stop a print since it wasn't coming out well.

The extruder stopped in the front on the right side. When I went to print again it would start calibrating from the front center then indicate a Z-axis era. I turned it off and on, again the same thing. I then decided to run the wizard, all was fine. When I went to print the head would move around and make this violate noise and vibration at each calibration point.

I contacted support, checked the screws on the motor shaft and then requested if I could move the extruder with it powered off. I did notice that when moving the x-axis to the far right it had lots of resistance and notice that rods were dry after 130 hours.

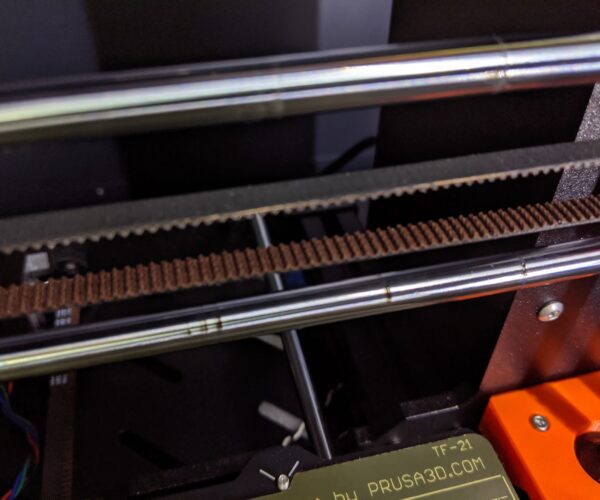

So I cleaned and lubricated all the rods. I then went ahead and printed successfully however, I'm concerned about what the picture shows. Rings of black grease from the bottom x-axis rod! The top is clean and so are the Y and Z rods. This was a kit, after all these hours printing it seems odd that something might be wrong?

RE: Grease on bottom X rod shows black after 130 hours

You don't grease the rods; you grease the bearings. The black stuff you see is grease pushed aside by the bearing grease seals. And dust.

They keep outside stuff outside, and grease inside.

Keep your rods clean and dry. Lubricate your bearing correctly, and consider yourself lucky the shipping oil on them lasted as long as it did.

RE: Grease on bottom X rod shows black after 130 hours

The instructions illustrate to use a small dab on the rods. Also from what I read the first maintenance is about 200 hours.

RE: Grease on bottom X rod shows black after 130 hours

https://manual.prusa3d.com/Guide/Printer+maintenance+tips/1437?lang=en

RE: Grease on bottom X rod shows black after 130 hours

Hello

and what do you think of using PTFE lubricant on rods to avoid dust to stick on rods ?

MK3S & Fusion 360

RE: Grease on bottom X rod shows black after 130 hours

Nothing beats clean.

RE: Grease on bottom X rod shows black after 130 hours

Of course I do agree.

but after cleaning 😉

MK3S & Fusion 360

RE: Grease on bottom X rod shows black after 130 hours

I will let someone else comment on their experiences with PTFE - but I think you will be surprised how little dust / dirt sticks to a clean polished rod.

What does accumulate, the grease seals will knock off (or push over into a black smudge...).

RE: Grease on bottom X rod shows black after 130 hours

So a frequent cleaning of rods (just a wipe) is recopmanded. Ok thank you for this tips.

MK3S & Fusion 360

RE: Grease on bottom X rod shows black after 130 hours

Before printing today I wiped the black rings off and relubricated. I'm going to be proactive and wipe them down and re-lube every week or two.

RE: Grease on bottom X rod shows black after 130 hours

If you actually lube the bearings - I would expect it would last six months to a year - at least.

RE: Grease on bottom X rod shows black after 130 hours

to lube the bearings I would need to disassemble?

RE: Grease on bottom X rod shows black after 130 hours

Well the bearings all have grease seals. They keep inside grease in - and outside grease out. So good grease really needs to go inside.

Next time you have occasion to tear down your printer - add greasing the bearings to your checklist.

RE: Grease on bottom X rod shows black after 130 hours

Are you sure linear bearing keeps grease inside like standard bearing ? Marbles seems to be opened not enclosed.

I will receive mine soon and will have a closed look.

MK3S & Fusion 360

RE: Grease on bottom X rod shows black after 130 hours

Here is a short article on bearing lubrication. Note that oil is not appropriate for vertical rods - it runs off.

https://www.linearmotiontips.com/lubrication-grease-or-oil/

RE: Grease on bottom X rod shows black after 130 hours

Thanks for this link.

So for me this is back to initial problem : Grease or PTFE.

Major inconvenience of grease is that it will make the rods dirty and capture dust, which is the opposit of what we want.

MK3S & Fusion 360

RE: Grease on bottom X rod shows black after 130 hours

You are forcing me to voice my opinions again.

1) Pack the bearings with anything. Lard is better than nothing. (a good grease is recommended though)

2) Keep the rods clean and dry.

RE: Grease on bottom X rod shows black after 130 hours

Hi,

This page explain how to maintain linear bearing : set-your-bearing-straight

MK3S & Fusion 360

RE: Grease on bottom X rod shows black after 130 hours

Hi,

This page explain how to maintain linear bearing : set-your-bearing-straight

Well I certainly approve of that post.