First Layer Calibration/ Bed Leveling Issues

Being new to 3d printing there is so much information out there that it seems i may not be able to see the wood for the trees when trying to figure out this issue.

Having complete calibration including first layer calibration i found that even the line within first layer calibration would generally appear to be nicely squished but always looks in some parts of the line to be a little rounded, although the final square would produce OK. but whenever i then came to print anything (sliced with cura or prusaslicer) i always had to adjust the Z to get the head closer to be bed or would not be squished correctly. (on the print following the calibration.

After putting up with this for a little (only creating smaller items in the center of the bed) when i came to do anything bigger i had contact issues with first layer not sticking (asif head was too far away).

I have always cleaned the bed with 99.9% Isopropanol before printing.

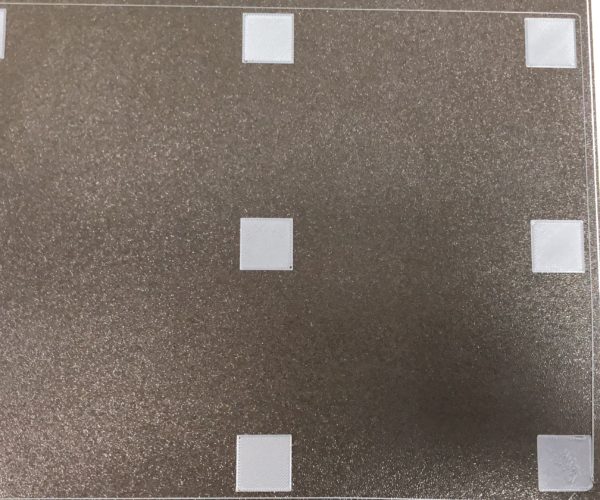

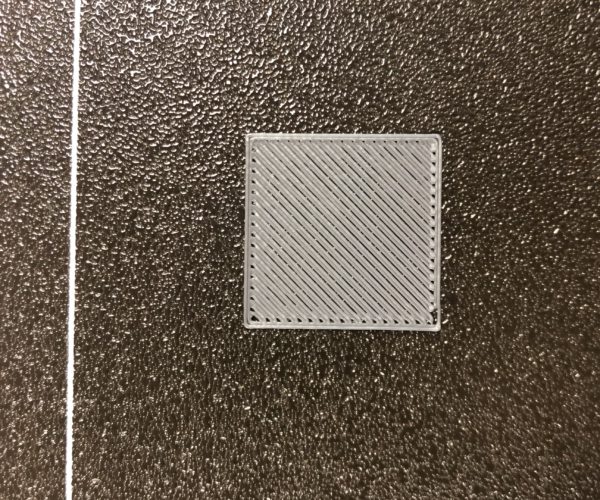

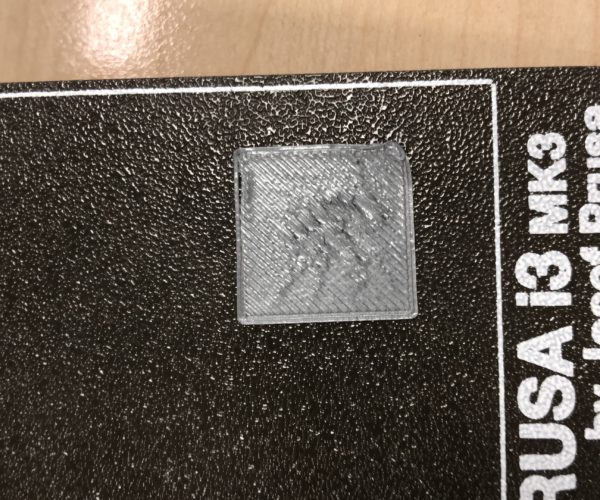

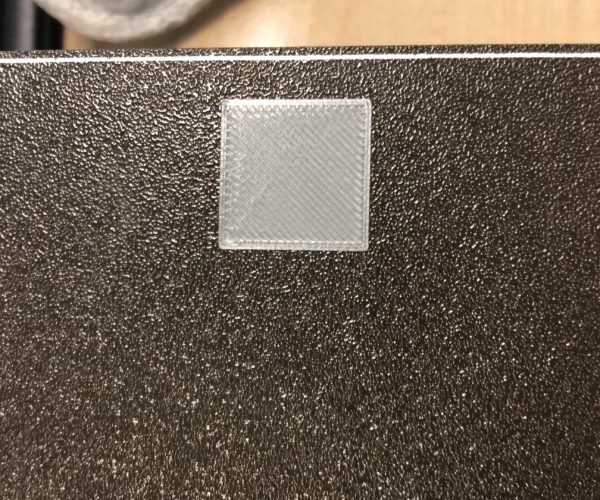

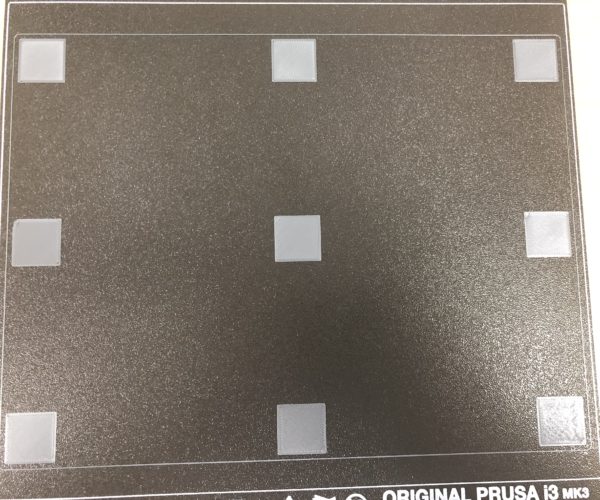

It seemed to be that in different areas of the bed the squish and adhesion would be different.. To try test for this i use calibration file that puts a square in each of the calibration points.. and low and behold every square is different, from some being nice, some not squished and the bottom right being terrible and close.

I thought the sensor and auto leveling are meant to adjust for these slight difference in height across the bed.. am i doing something wrong or is there a guide to try improve this?

So far i have done these.

- Took off the the bed (including removing frame from bearings/rods), re-attached and re calibrated.

- Adjusted the Pinda sensor and re-calibrated

The sheet does not appear to be warped in any way and is flush to the heated bed with no raised spots etc.. I always tried setting the initial calibration to the 7x7 instead of 3x3 and still the same result.

Any ideas would be appreciated.

You can see all the variances in the below images.

RE: First Layer Calibration/ Bed Leveling Issues

Hello,

is the calibration menue , is there the bed leveling OK? Which values are there for the bed? Which FirmwareVersion are you using (Support Menue)

Thx for the informations - Carsten

RE: First Layer Calibration/ Bed Leveling Issues

One major helpful setting is in settings, mesh level, select 7x7, not 3x3.

The next important setting is in custom gcode in the printer profile, is to set M860 to control PINDA temperature before mesh level occurs. If the PINDA is warming up during the level, each spot measured will be slightly different. Soaking the PINDA to 35 or 40c reduces the front to back variation due to PINDA temperature rise.

RE: First Layer Calibration/ Bed Leveling Issues

@umaker @tim-m30

Hi Guys..thanks for your response, The Bed level corrections are all set to 0 at present.. Firmware is 3.8.0-2684...

I have reset the machine again today, also reset and re-calibrated after going through the manual (just incase i has missed anything.. i dont think i have) and re-seating the PINDA sensor. Although these appear to be better, there is still the obvious difference across the bed.

I also added the custom gcode for the PINDA temp which doesnt appear to have made much difference, although the perimeter skirt sometimes doesnt adhere in places so gets in the way. First print this did adhere and i had the result attached.. adding the gcode and it i didnt get a decent result due to the perimeter not sticking and then getting in the way later on.

I dont ever seem to have an issue with a single line adhering when doing the calibration though.

As with my post i have already tried changing to a 7x7 instead of a 3x3..

If it would help i could make a video of the calibration and also the alternative 1 layer test so you can see how this seems to print. I dont like that i cant seem to trust the first layer to print and therefore always have to sit to watch that and restart a few times if on a larger piece.. But you can see from the XYZ cube that in the most part a print that is printed in a half decent areas produces alright...

RE: First Layer Calibration/ Bed Leveling Issues

The adhesion issues are related to your mishandling the sheet. A thumbprint is about the worst thing you can do to make your life difficult. PLA and oil do not mix. And soap and water is the only way to adequately clean oil off the sheet. Handle the sheet by the edges: never touch the print surface. Use tools to remove parts: plastic razor blades work well.

Also - most textured sheet owners say washing the sheet in soap and water was required to make PLA stick; and after the wash alcohol scrubs works for a while.

The PINDA soak to a higher temp helps most when doing several prints in a row. If you only print once and let the printer cool down for hours, you might not see a difference between prints: but warming up before mesh level does allow for a bit more consistent mesh level from front to back because the PINDA is less likely to warm a lot more along the way like it does when you start cold.

That last image of the test coupons looks pretty even; but the center is too low, forcing everywhere else low, too. I'd increase Live-Z about 25 microns (e.g., -0.800 to -0.775). Even 50 might be needed, but don't go so far you get gaps.

That said, without the PINDA soak, subsequent Live-Z tests will make you chase your tail. One test starts at 25c, the next at 35c, and the next 40c ... all incurring the temperature variable gods of PINDA. And yes, the PINDA is that temperature sensitive.

RE: First Layer Calibration/ Bed Leveling Issues

As a complete beginner in 3d printing, who has mounted a kit recently, I had a lot of problems doing the first layer calibration yesterday. I have a textured plate and PLA didn't stick at all at the surface. I cleaned it multiple times, and was thinking of acetone and even sandblasting the plate.

I did all the forum to figure out what I was doing wrong, and questionned myself about my quality of build. The solution for me was finally very simple.

In my case speed "out of the box" was 100 mm/s, and I got a lot of warping and could never end one single print. Then, by pushing the knob during print and entering the tune menu I finally slowered the speed to 60 mm/s. This was a real game changer and suddenly my printer was behaving like a charm. I was able to print those rectangles nicely and to do a single layer calibration without any problem. This night I printed my first print without any problem.

So as senior member of the absolute beginners my advise for first layer calibration problems on a new build would be: Slow down your speed

Regards Michael