RE: Extruder clicking and PLA filament jammed

@dzym-fardreamer

Once I moved back to a .4 nozzle I did not experience any issues (well related to the topic issues lol) while printing. But to be fair I have not been printing with ABS which is when I really experienced the clicking and jams. I just switched out the hotend with a Triangle Labs Dragon hotend and I will try a smaller nozzle size and see how it goes. If it works out I'm definitely going to pick up a Copper Head or Mosquito as I have been eying them for awhile now.

RE: Extruder clicking and PLA filament jammed

@anachronist

I had the same problem and I could only fix it by replacing the E3D extruder and heatbreak by a coppearhead extruder. https://www.sliceengineering.com/products/copperhead%E2%84%A2

You dont kneed the heatsink, just the headbreak and the head of the extruder.

I had three printers with problems and since the update, 0 jams, for some months

Well, I've had no problems all year with the stock Prusa MK3S until now. I am wondering, what has changed to cause it to start jamming all of a sudden? Spending $60 on a new hot block and heat break is one way to solve the problem, but I really want to know what is different now than a week ago, that causes my extruder to jam after just a few minutes from a cold start.

RE: Extruder clicking and PLA filament jammed

If you have changed nozzles, there is a good chance the heat break/nozzle fitment is not where it needs to be.

Upload a photo of your heater block showing the gap between the block and the nozzle hex.

RE: Extruder clicking and PLA filament jammed

If you have changed nozzles, there is a good chance the heat break/nozzle fitment is not where it needs to be.

Upload a photo of your heater block showing the gap between the block and the nozzle hex.

I did change the nozzle in July. The original one got clogged due to printing ABS (my first time ever), and it wouldn't clear out properly when switching back to PLA, so I removed the nozzle and replaced it with a new one, which I had also bought from Prusa. It worked just fine for my next PLA project, of which I printed at least 4 iterations before I was satisfied with my design. The printer has been unused since then, until yesterday when I tried to print some lion teeth I designed for a Halloween necklace. And it is jamming constantly. Tightening the idler helped a bit, but at some point it just stops feeding filament.

I removed the silicone sock and took a picture, which is attached. What should I be seeing? I believe it looks the same as the previous nozzle. I didn't know how dirty it was until I took this photo.

RE: Extruder clicking and PLA filament jammed

Try cleaning nozzle.

Do a few retractions.

Do a cold pull.

(you could try above with higher temperature filament).

or change nozzle to be 100% that nozzle is not clogged.

RE: Extruder clicking and PLA filament jammed

The nozzle looks mounted properly; so not what I was initially thinking.

A couple of quick checks:

- Nozzle temp is actually reaching 200c or higher?

- Extruder fan is spinning - at speed : you can feel air coming out the other side - no cobwebs from Suzie Spider the Homemaker?

- You've tried new filament (dry as opposed to stale perhaps wet filament)

- You've done a cold pull and can see a well defined nozzle cone

- You've flushed the nozzle at 280c with at least 250 mm of PLA, 500 mm is better

- You've adjusted the Bondtech Gear tensioner - tighter, and looser

- Inspected the Bondtech Gears for debris in the teeth and they are lubricated (the metal to metal drive gears need grease)

RE: Extruder clicking and PLA filament jammed

The nozzle looks mounted properly; so not what I was initially thinking.

A couple of quick checks:

- Nozzle temp is actually reaching 200c or higher?

- Extruder fan is spinning - at speed : you can feel air coming out the other side - no cobwebs from Suzie Spider the Homemaker?

- You've tried new filament (dry as opposed to stale perhaps wet filament)

- You've done a cold pull and can see a well defined nozzle cone

- You've flushed the nozzle at 280c with at least 250 mm of PLA, 500 mm is better

- You've adjusted the Bondtech Gear tensioner - tighter, and looser

- Inspected the Bondtech Gears for debris in the teeth and they are lubricated (the metal to metal drive gears need grease)

Yes to all of questions.

I did discover that there is a cold pull, and a better cold pull. My cold pull consisted of heating up the nozzle, manually pushing PLA filament into it as it cooled to 160C, waiting until it reached below 90C, and pulling it out. I would get a stretched filament with a well-formed nozzle cone tip.

Then I tried the cold pull in Prusa's knowledge base. The difference is, you let the nozzle cool all the way to room temperature, then heat it back up to 85C and pull out the filament. The filament doesn't stretch then... and that mattered. I pulled out a filament with a well-formed tip and a ring of black stuff just above the tip (image attached). It seems, with my previous cold pulls, the filament was getting through that ring and through the nozzle, but the stretching of the filament from the pull left the ring in place.

I did a couple more to be sure it was clean, and tried my print again. This time it got almost all the way to the end before it jammed. Damn.

Prusa Support thinks it may be the PTFE tube inside the extruder is damaged or has a burnt end. The problem is I have to disassemble the thing to get at that little tube. Other than messing around with retraction settings (which I have never had to do), that may be the next logical step. That, or print my part halfway, pause it and let it cool, then print the rest.

RE: Extruder clicking and PLA filament jammed

Update: The PTFE tube was in perfect condition.

RE: Extruder clicking and PLA filament jammed

@anachronist

This was happening a lot to me came across this vid found it interesting watch

RE: Extruder clicking and PLA filament jammed

@anachronist

This was happening a lot to me came across this vid found it interesting watch

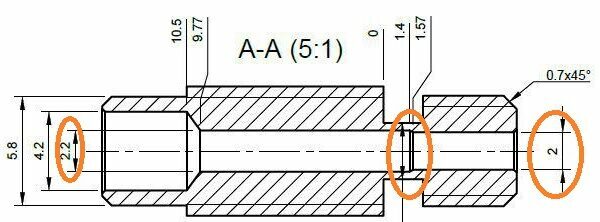

That was interesting. Well... there's no way I'm going to use oil, and I already use a sock. The main contributor to preventing jamming seems to be the bore of the heatbreak in the MK3S going from 2.2mm to 2mm, whereas the MK2 heatbreak bore is a straight 2mm all the way though.

The video also said that the reason for that 2.2-2mm bore is for multi-material printing. Because I have an MMU2S (and I use it), I'm uncomfortable with replacing the heatbreak if the original heatbreak is intended for use with the MMU2S.

The video also recommended raising the printing temperature to prevent jams, although you'll get more stringing. I was printing at 205, now at 210, and that helped, but what seems to have helped the most is to tighten the idler door tension screw until the screw tip is flush with the outer surface of the extruder.

RE: Extruder clicking and PLA filament jammed

@anachronist

I did opt to replace the heatbreak with the one that does not have the increased diameter for multi material, It wasn't that hard to replace the online instructions are very informative and I just took my time. Since replacing the heatbreak I have not had a blockage or any clicking noises and the detail is very nice so for me I would count this as a success from my perspective

RE: Extruder clicking and PLA filament jammed

@the-mad-jedi

I don't doubt it, but are you also using the MMU2S? That video says the heat break with the expanded bore is designed that way to make filament changes work better.

RE: Extruder clicking and PLA filament jammed

@anachronist

Pretty much all of the stuff I print is then detail painted so i don't use multi color so the expanded bore has no use to me, I am more after detail and less jams

RE: Extruder clicking and PLA filament jammed

@anachronist

I had the same problem and I could only fix it by replacing the E3D extruder and heatbreak by a coppearhead extruder. https://www.sliceengineering.com/products/copperhead%E2%84%A2

You dont kneed the heatsink, just the headbreak and the head of the extruder.

I had three printers with problems and since the update, 0 jams, for some months

@dzym-fardreamer

I'm going to try this. When you say "head of the extruder" do you mean the hot block?

RE: Extruder clicking and PLA filament jammed

Not the Hot block but the heatbreak there are 2 types the new design with the 0.2 flange at the top and the older one that is 2mm all the way through. I replaced the new design for the older one and got much better results

RE: Extruder clicking and PLA filament jammed

Top End Bottom end

Bottom end

The New Heat Break with the 0.2 flange

RE: Extruder clicking and PLA filament jammed

Same issue on one of my mks3's.

I can get around it by preheating to 240 and maintaining between 230-240 printing temp.

Less than ideal.

Print quality seems unaffected.

RE: Extruder clicking and PLA filament jammed

Just a small update. Since my last post in this thread, I had to travel to the other side of the country for 3 months. After I returned home I could resume troubleshooting on my printer. The last thing Prusa support suggested is to re-apply the thermal paste to the heat break.

Based on other information I found, this is sound advice.

Jams can be caused by improper heat transfer between the heat break and the heat sink. So even if your hotend is running at a nice stable temperature, the throat of the heat break isn't getting the heat dissipated and the filament is melting up too high. This causes a jam, and it can be fixed by removing the heat break, applying fresh thermal paste, and reassembling the extruder.

Prusa support said that any thermal paste that can withstand 300°C will work. In the United States, this is hard to find. I did find one called Thermal Grizzly Kryonaut at $10/gram, and it can take 350°C and has four times the thermal conductivity of the paste that came with the printer. However, I needed to order some Prusament anyway, so I bought another tube of the Termopasty AG Silver, which is available only in Europe. It should arrive in a few days, and take me another few days to get around to disassembling and reassembling everything. I'll update this thread when I have some results.