Under extrusion(?), clicking sound and print failure

Hi all,

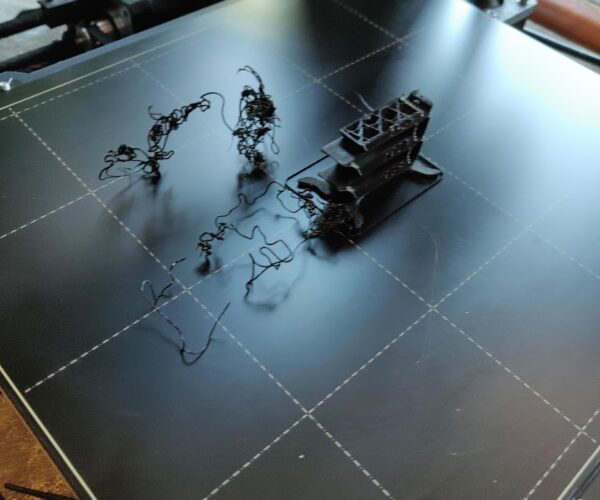

after a long delayed upgrade from Mk2 MMU1 to MK2.5s MMU2S, I did not manage to print successfully. 1st I encountered the famous spaghetti monster

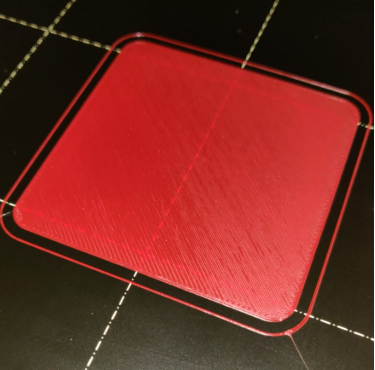

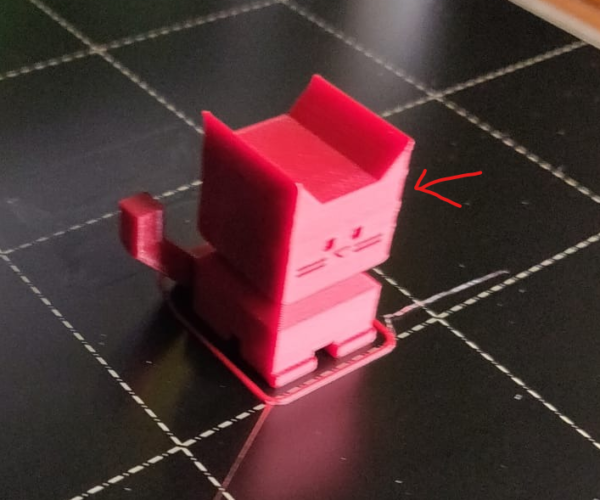

Which I assume was due to bad 1st layer (why did I print in black to make calibration? 😐 ) Once I was finally able to have a good 1st layer (switching to red PLA was much much easier to adjust) I was able to print I was somehow able to print the Calicat (with some slight imperfections).

With the joy of 1st successful print, I started tried ~10 prints with different settings (mainly playing around temperatures, speed, a LOT of cleaning, cold pull, etc...) I've never been able to print bigger objects. And after some point, not even being able to reprint the Cali cat. Most of the time, I was hearing the cliking sound in the extruder and it just stop extruding.

For example, I was trying to print the small tea holders (left is 100% infill, right is 20%):

I was assuming that I may have tighten too much the extruder tension screw, but even unscrewing it as much as possible while leaving it there, the clicking sound and the extrusion stopping still happened. No blob or apparent clog. I was able to unload the filament without any issue (even though it looked like it was chewed where the gear was). I cleaned the gears just in case (all good), checked the alignment (all good), cold pull (did not seem to have any dirt or blob), checked the PTFE tube (all good), used the acupuncture needle.

It seems to happen when there is suddenly a lot of retraction and deretraction. I tried to reduce the retraction speed but did not change much (left picture).

Settings are pretty much the default one for the MK2.5s MMU2s at 0.2mm layer height. Bed temp at 67, 1st layer 215C, remaining layers at 200C. retraction speed at 30mm/s (left), 35 mm/s (right).

I ordered a new hotend (E3Dv6) to test if that could come from that. Apart from that, I am not sure what to try or do to make this work. I'd welcome any suggestion or to point in the right direction.

Cheers

Best Answer by Mark Mac:

I was having extruder clicking problems for well over a year now. It was driving me crazy with the failed prints. No rhyme or reason to the failures. Finally I watched a video ( ) on the issue that resolved it. Basically, I replaced the MK3 heatbreak with a MK 2.5 heatbreak. The bore on the MK 2.5 heatbreak is constant at 2.0 mm, where the MK 3 bore varies from 2.0 mm at the hotend of the heatbreak to 2.2 mm. This lip is too much into the cooling zone of the heatbreak, so on a retraction the large bore cools the filament enough to block the flow of the filament on the return to positive flow causing the extruder to skip (i.e. click) and the filament to jam. The video really explains this issue very well. I replaced mine and the problem went away. If you do not want to replace the heatbreak, you can do the following in an attempt to mitigate this issue, but it does not always work (it was hit or miss for me):

1. Use a silicon heat sock on the heater block for better constant nozzle temperature.

2. Reduce your retraction movement to 0.4mm to 0.0 mm. You may need to experiment with this.

3. Increase the nozzle temperature. (e.g. PLA at 215/210 deg C to 215/240 deg C). Again you will need to experiment with the temperature to see what would work best.

I hope this helps and solves yours and others problem on this issue.

RE: Under extrusion(?), clicking sound and print failure

I was having extruder clicking problems for well over a year now. It was driving me crazy with the failed prints. No rhyme or reason to the failures. Finally I watched a video ( ) on the issue that resolved it. Basically, I replaced the MK3 heatbreak with a MK 2.5 heatbreak. The bore on the MK 2.5 heatbreak is constant at 2.0 mm, where the MK 3 bore varies from 2.0 mm at the hotend of the heatbreak to 2.2 mm. This lip is too much into the cooling zone of the heatbreak, so on a retraction the large bore cools the filament enough to block the flow of the filament on the return to positive flow causing the extruder to skip (i.e. click) and the filament to jam. The video really explains this issue very well. I replaced mine and the problem went away. If you do not want to replace the heatbreak, you can do the following in an attempt to mitigate this issue, but it does not always work (it was hit or miss for me):

1. Use a silicon heat sock on the heater block for better constant nozzle temperature.

2. Reduce your retraction movement to 0.4mm to 0.0 mm. You may need to experiment with this.

3. Increase the nozzle temperature. (e.g. PLA at 215/210 deg C to 215/240 deg C). Again you will need to experiment with the temperature to see what would work best.

I hope this helps and solves yours and others problem on this issue.

RE: Under extrusion(?), clicking sound and print failure

Hey Mark Mac,

thank you for the help! I wish I'd seen this video earlier! I had no idea the design for the heatbreak changed. I still have the old heatbreak for the MK2 so if nothing improve, I'll change to use this one. I checked my filaments that I needed to cut after a jam and it match what was explained int he video (slightly larger bulb at the end which cause the jammed). Just in case this has caused some damaged on the PTFE tube, I replaced it.

In the mean time, I played with the retraction settings and got some luck! I reduced by twice the retraction length (I'm now at 0.4mm) and increased the retraction speed. I got some luck and was able to have a fully successful print! (And no stringing as a bonus!). I'm continuing the test to see if it resolved it or it was just a Sunday evening lucky shot.

I am printing a 3dBenchy. Let's see how it goes.

Thank you so much!

RE: Under extrusion(?), clicking sound and print failure

the Modified heatbreak came out part way through Mk2 lifespan, so your spare, may be the modified type If you still have the PRE MMU1 heatbreak, you should be ok! the modified heatbreak was actually brought in, because the MMU1 was having difficulties!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Under extrusion(?), clicking sound and print failure

Ahh, thank you Joan. Good to know. I tried with my old extruder but it did not improved so I may already have the modified heat break (I had MMU1).

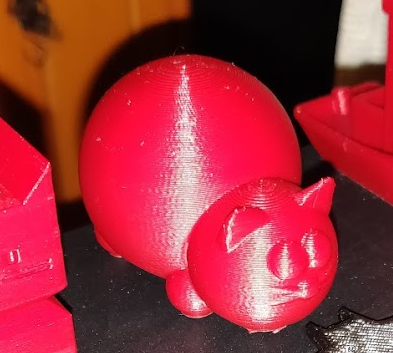

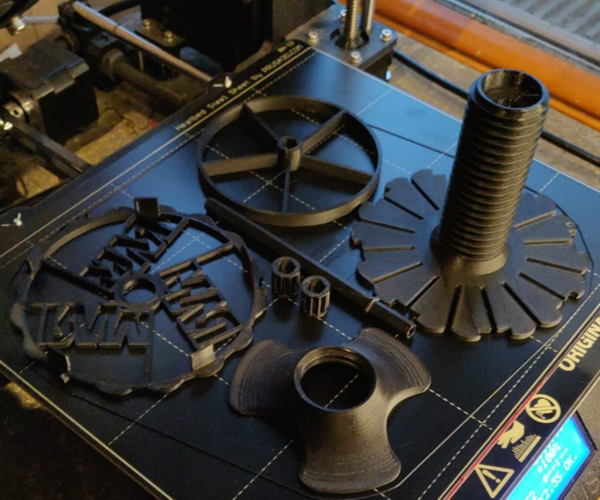

I made some very promising progress with small prints. I mean small in footprint, around 2 to 3h print time. And they printed to perfection:

But when going into longer prints with the exact same settings, I always get stuck. Most of the time, event before 2h prints. Like this one:

This is the farthest I got (~4h):

And this is what puzzled me: no clicking sound anymore. It just starts under extruding at some point and then stops. So far, I'm not able to understand what that could mean. I tried a few cold pull and nothing out of the ordinary came out of it. I removed the PTFE tube to check any damage but all good as well.

I am printing again with the red filament to see if it gets better.

I'm receiving a new hotend today. Let's see if that helps improve.

Cheers!

RE: Under extrusion(?), clicking sound and print failure

@roy-corey

I always reduce my retractions because I found that standard retractions lead to clogs.

so My Mk2 with MMUv1 runs at 2mm retraction, rather than the standard 4mm retraction(It's a Bowden setup, hence the larger than normal

retraction)

My Mk3 runs at 0.4mm retraction instead of o.8mm

you could also try, 'Only Retract When Crossing Perimeters' "Print Settings>Infill>Advanced (in expert mode)

this reduces the total number of retractions and reduces the 'hammering' which can cause the end of the filament to enlarge and clog...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Under extrusion(?), clicking sound and print failure

I set up my retraction settings at the same level you mentioned and it made a huge improvement on both speed and quality (0.4mm for retraction length and lift Z at 0.3). I was finally able to print my 15cm batman without any issue with my red filament. But when I tried with the black one, I almost immediately got issues (the black one is Prusament while the red is not 🤔 They have been stored for 2 years without being opened). I will replicate the setup of the red filament for the black one just to confirm (or not) it is indeed also a filament issue (moving it on extruder 1 mainly).

Thank you again, I able to print now even if not everything is resolved

RE: Under extrusion(?), clicking sound and print failure

the Modified heatbreak came out part way through Mk2 lifespan, so your spare, may be the modified type If you still have the PRE MMU1 heatbreak, you should be ok! the modified heatbreak was actually brought in, because the MMU1 was having difficulties!

Shh! The conspiracy theory is that Prusa surreptitiously slipped the design change in sometime after the release of the Mk3. If people realize that there are fixes other than outright replacement of the heatbreak (last year's hot craze) or twiddling extruder motor currents (this year's hot fad) they might end up spending time figuring out what the underlying problems are.

RE: Under extrusion(?), clicking sound and print failure

Hey everyone.

I finally got a new hotend (I believe with the updated heat break, ordered it from the E3d website) and it is now fully functional! Yeah \o/ I am not exactly sure what was the problem with the previous one. I don't have any clicking sound anymore and I am able to print multi material without any issue. Thank you for your help 🙂