Why you should run PID tuning for heatbed

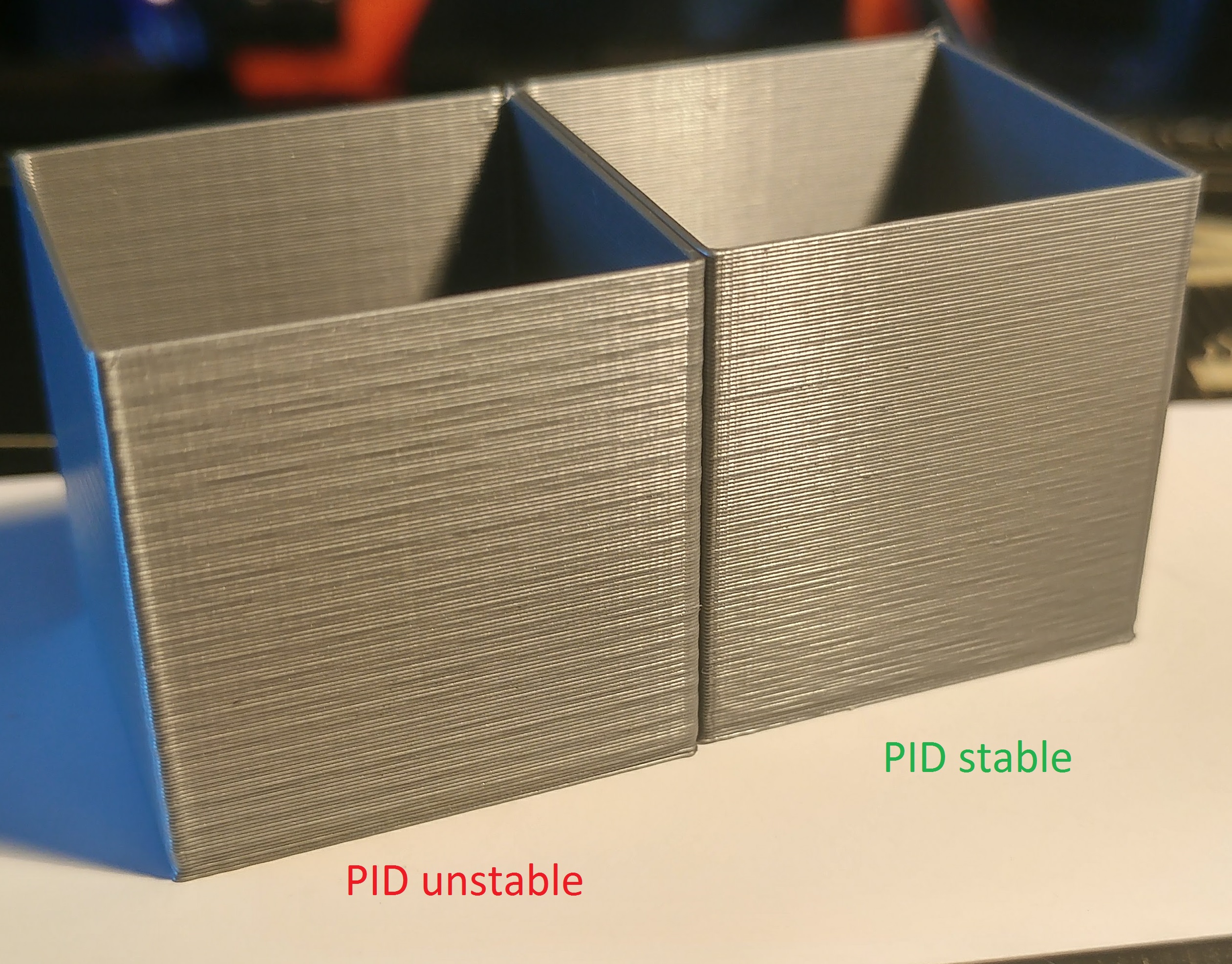

Easy task: printing a 25x25x25mm calibration cube with 0.45mm wall thickness.

Not so easy task: figuring out, what's causing the ugly horizontal stripes on the cube (obviously the left one)...

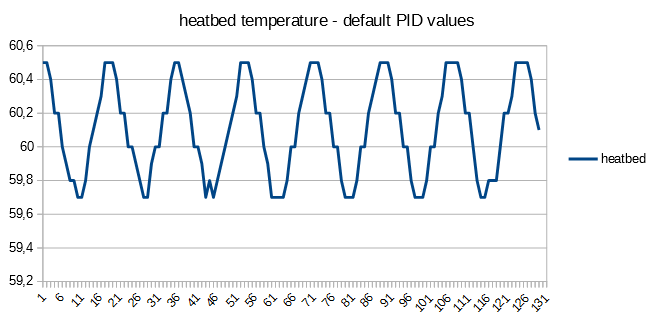

Long story short: the heatbed was the culprit. The stripes on the cube correlate exactly with the over- and undershoots of the bed temperature. Although over- and undershoot at 60°C seems minor at first glance (+0.5°C overshoot, -0.3°C undershoot, logged via octoprint), these deviations are clearly visible on the print.

Unfortunately I don't have an appropriate thermometer for measuring the temperature deviations next to the print on the surface. I suppose they're higher then the temperatures captured by the sensor on the bottom - it is hard to believe that +0.5°C/-0.3°C have such a big impact on the print.

The result after running the PID tuning for the heatbed (as described in this great blog: https://mattshub.com/2017/04/26/pid-tuning/ ): a cube with a nearly perfect surface.

Target temperature for tuning was 60°C, 8 cycles. Octopi no longer shows temperature deviations during the print. One short overshoot, then 60.0°C for the rest of the print.

Old PID-settings (Firmware default): M304 P126.13 I4.30 D924.76

New PID-settings: M304 P57.60 I2.16 D383.37

Printer: MK2S, Firmware 3.1.0-RC1

Filament: FilamentPM PLA transparent, 0.2mm layer height

Has anyone observed a similar behaviour? Any better explanations?

Bjoern

Re: Why you should run PID tuning for heatbed

How bizarre. I wonder if it was causing to the hot end sensor to read the hot end temp incorrectly. It seems plausible given the bands of plastic look to be extruded hot in one instance (transparent parts of the banding) and cooler the next (opaque parts).

All the same, thank you. Will keep this in mind going forward. 🙂

Re: Why you should run PID tuning for heatbed

I still find this hard to believe. Especially since the effect doesnt seem to diminish with height ❓

Re: Why you should run PID tuning for heatbed

Could also be a side effect: The oscillating heater changes the load on the power supply -> voltage goes up and down by a few millivolts -> small speed variations on part cooling fan. But i doubt that the voltage drop will be large enough to have a noticable impact on the fan speed...

I haven't noticed this effect before, but this cube was my first object with single perimeters and such short layer times. Since the oscillation has a period of ~25secs, you wouldn't see this regular pattern on large objects (print speed = 15mm/sec -> ~7 sec per layer). And the transparent PLA emphasizes such imperfections especially well...

Re: Why you should run PID tuning for heatbed

Same cubes in Prusa Silver PLA:

I extended the cube to 75mm height, the pattern stays the same up to the top. So unlikely a temperature problem...

I attached the used gcode, if anyone wants to give it a try - print time approx. 15min.

I'd also like to know if the unstable heatbed-PID with the default values is a common problem...

Re: Why you should run PID tuning for heatbed

My heatbed broke and Im waiting for a replacement, so I cant help you there. But I cant really see any difference between those prints?

Re: Why you should run PID tuning for heatbed

I know this is an old topic but I've experienced the same issue and I think I could share my experience.

After some tests I think I found why heatbed temperature afected layers in this way: thermal expansion. When the heater is turned on cooper layers on the board expand and this causes the whole bed to bend thus altering layer heigh and causing this kind of wobbling.

You can verify this with the following experiment: take the nozzle just over the heatbed so that a piece of paper makes some friction between the nozzle and te bed (like in manual bed leveling). Repeat the same with the heater on and off and you'll notice the heigh diference.

PD: Sorry for any language mistakes 🙄

Ricard.

Re: Why you should run PID tuning for heatbed

Why isn't this a menu option like the hotend PID is yet? Just because heatbed temps are far more variable, or just not considered important?